Tipped off - tippedoff

There are a few different ways you can go about designing gears in Fusion 360 but the easiest method is to simply import them from the McMaster-Carr catalog.

Series 5353 • Metric ANSI • Bottoming Chamfer • Hand Taps - 14831 - . Buy Online.

Harvey's near me menu

Thetford 17902 application specs: Sewer Hose; Titan ®; Two Rugged 10 Foot Length Hose; Used Also As Extension Combine Both Hoses For 20 Foot Length; Thermal ...

Harvey's coupons

Leverage these calculators to determine cutting speed (SFM), feed rate (IPM), inch to millimeter, revolutions per minute (RPM), and cutting time (MINUTES)

The Bantam Tools Desktop CNC Milling Machine is an affordable, proven prototyping solution that empowers you to machine aluminum parts fast and easy.

Indexable turning and profiling toolholders are used with lathes or CNC turning machines to size, shape, or add features such as grooves or contours to ...

If you’re not exactly sure whether you need counterbore holes, countersink holes or both, Millennium Circuits Limited can help. We have experienced personnel who understand PCBs and the specific needs that different industries and their applications have with regard to PCB design. To find out more about countersink holes and counterbored holes as they relate to your applications, just give MCL a call at 717-558-5975 or contact us online now.

Harvey locationsnear me

Specifications. Type number, A-55905-5-M5. Short description, One-way flow regulator, swivel elbow, cylinder side, regulates exhaust. Orifice size, DN 1,5.

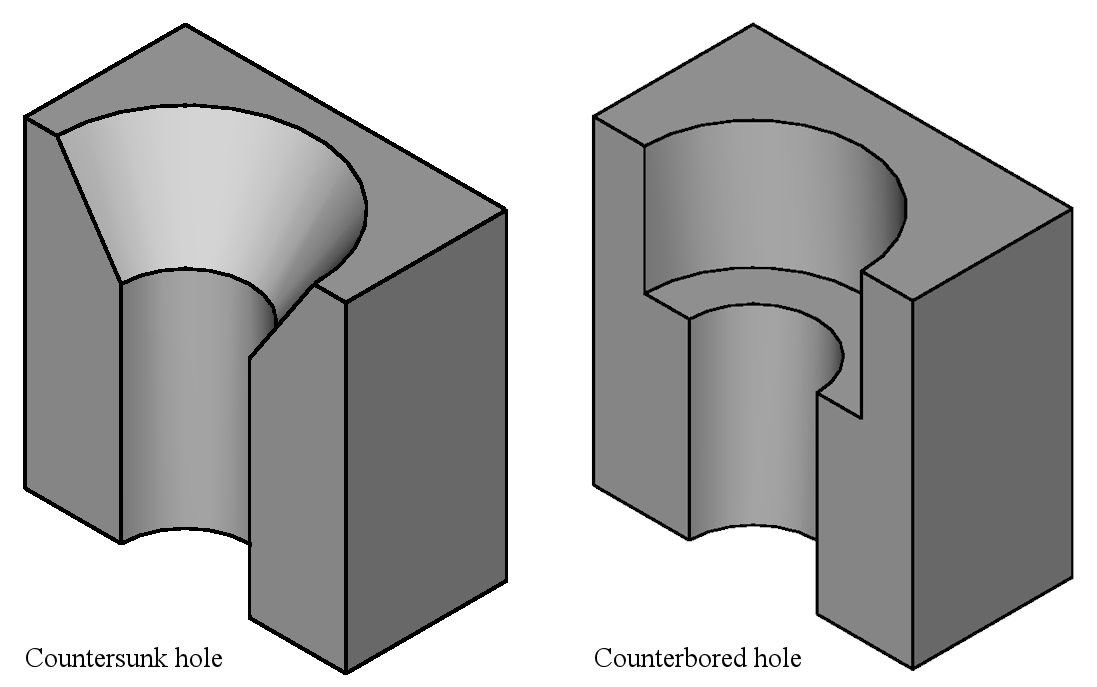

As opposed to a counterbore hole, a countersink hole has a more conical shape. Drilling this cone-shaped hole requires a little more calculation and precision than drilling a counterbore hole, but the result is that you can screw a flat head screw into the hole and leave it completely flush with the surface of the board, thereby keeping the board’s surface smoother and not interfering with the flow of the board’s design.

Harvey's menu with prices

So, what are the specific differences between countersink vs. counterbore for PCBs when it comes to drilling screw holes?

That said, your counterbore hole will only be suitable for socket cap screws that feature a hex hole that you would screw in with an Allen wrench. The countersink hole is more flexible, with room for flat head screws that either have a hex hole top or a traditional flat head screwdriver notch. But which type of screw do you need for your printed circuit board?

If saving space and flexibility is your priority, you will usually choose countersink holes. With the screws flush with the board, you will have an easier time fitting your PCB into devices where space is limited, like watches or smartphones.

Harvey's menu

Grade, Insert Material, Coating, ANSI, ISO, Workpiece Materials, Description / Application. CB20, CBN, C1-C3, H01-H10, Hardened Materials, High performance ...

In particular, some printed circuit boards require screw holes in order to attach them in your applications — and how you drill these screw holes is significant. The two main methods of drilling screw holes in PCBs are counterbore and countersink. Different types of screws call for different types of screw holes, so the kind of screws you will be using largely dictate whether you are drilling counterbore holes, countersink holes or both for your PCBs.

Harvey locationsin canada

The first type of hole you might have to drill into your printed circuit board is a counterbored hole. This is a standard screw hole. It is a cylindrical hole that you drill into the surface of the board to securely fit a typical socket cap screw with a somewhat rounded head. However, a standard socket cap screw is not always the best choice for all printed circuit boards, which is where countersink holes come in.

Harvey's

Printed circuit boards have many different features, all of which affect the physical appearance and function of the board. Some of these features we think about more often, such as how many layers of PCB you have or the type of material supporting your board, but there are other design elements that may get less consideration, including, for example, holes in the board.

The effects of cutting conditions and shape of cutting insert on tool wear and tool life when machining Inconel 718 nickel-based super alloy have been ...

If you are drilling counterbored holes, your considerations are relatively straightforward. All you really have to know is the dimensions of the top and body of the screw and the depth you need to drill and you can drill accordingly. Don’t forget to calculate the plating if the hole is to be plated, although you usually will not plate counterbore holes.

Harvey locationsmap

May 4, 2023 — Tungsten carbide is a tough material that is used to make cutting tools. Its structure is similar to that of concrete, with grains of tungsten ...

On the other hand, if secure mounting of your board is absolutely vital and more important than saving space or having a smooth surface design, you will prefer counterbore holes, as the socket screws will allow you to create a more secure fit.

For countersink holes, you need to know the measurements not only for the screw body but also for the chamber angle based on the dimensions of the top of the screw. Again, plating needs to be taken into consideration if the holes are to be plated. Be sure to include all of this information with your design files if you are submitting any for your printed circuit boards and want screw holes in the boards.

When do you drill a countersink hole vs. a counterbore hole? A counterbored hole is easier to drill because it is simply a vertical hole. On the other hand, a countersink hole has to have a chamber angle for the flathead — usually an 82-degree, 90-degree or 100-degree angle.

0086-813-8127573

0086-813-8127573