Titan Promotions - titan tools

Dijetcatalogue

As a jeweler you really should be using metric drill bits. Period, end of discussion. But I decided that I should include additional information as it makes the discussion complete. A common standard for metric drill sizes is the Renard series, which uses a simple factor to determine the diameter. I will not go into that as most jewelers use very small drill bits. I personally rarely ever use one over 5mm in size. for me, as a general rule, I tend to buy my drill bits in sizes that allow me to set round gems. The drill bits that I use every day range in size from 0.8 mm (0.0025 ct) to 5.0 mm (0.50 ct) in diameter and I tend to buy them in the sizes closest to the gems I set.

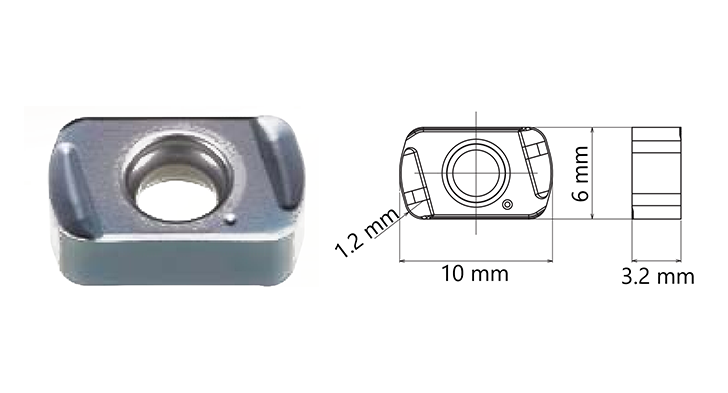

The QM Max G2 is a double-sided insert with 4 cutting edges. This geometry is designed for roughing and achieving high metal removal rates. The one size insert covers a range of diameters from 5/8” to 2” bodies. Max depth of cut on this high feed is .040” and can handle a heavy chip load. There are two styles of inserts for hard milling, one being a chip breaker and the other a flat top. The flat top “ENMQ” insert is the best for 60 HRC material and interrupted cut. This cutter also has an insert that is excellent for machining high nickel alloys.

0086-813-8127573

0086-813-8127573