Titan USA Carbide Drills: Jobber, Stub, & Straight Flutes - straight fluted drill

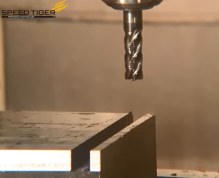

Peckdrilling with end mill

Many variables affect the performance of threaded holes and the taps used to generate them. One very important factor is the drill size used to produce the hole that will be tapped. Most tap drill charts call out only one tap drill size, and that will produce an approximate 75 percent thread. In general, tap tool life can be increased significantly by using a lower percent of thread and we suggest using values between 60% and 70% for most applications. Thread strength is not directly proportional to percent of thread. For example a 100% thread specification is only 5% stronger than a 75% thread specification but requires 3 times the torque to produce.

Center cutend mill

DrillMillBit

Metric threads of the International Standards Organization (ISO) have the same 60-degree thread form as UN threads, though the diameters and pitches are not interchangeable. Metric tap drill charts have the same drill size problem in that they use the same formula as that employed for the obsolete AS threads. In both ISO and UN thread series, having a range of useful drill sizes allows designers and machinists to tailor effective thread depth for long holes, various materials and thread strength requirements. It also allows for the combining of inch and metric taps and drills where convenient to do so.

0086-813-8127573

0086-813-8127573