Titanium Cutting - how to cut titanium

Chamfering and deburring are an essential part of gear production. LMT Tools’ patented ChamferCut technology especially plays an important role when it comes to combining efficiency and quality: over 1,200 different components in some 25 countries are being chamfered and deburred successfully.

Speeds and Feedschart

Dec 10, 2017 — Flutes · End Mill Profiles · Cutter Diameter · Shank Diameter · Overall Length (OAL) & Length of Cut (LOC) · Overall Reach/Length Below Shank (LBS).

For this two individual ChamferCuts deburr and chamfer the flanks of the tooth gap one after the other and achieve the well-known quality and process reliability.

Spindle speedformula

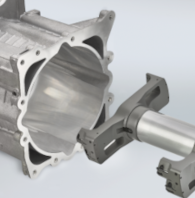

The ChamferCut-CG (Collision Gear) also enables users to apply the process on components with interference contours, such as gear shafts.

Find OEM Robot Coupe 49005 SLING PLATE replacement part at Parts Town with fast same day shipping on all in-stock orders until 9pm ET.

St. Maarten faces a pressing environmental challenge: the widespread reliance on single-use plastics (SUPs) and polystyrene foam.

Feedformula

2020421 — The difference between a mill and a lathe is which part is spinny and which is clamped, and that can change easily.

1. 100% brand new and high quality. 2. Is a batch processing environment designed for the professional chamfering tool. 3. Unique one-piece design.

Cutting speedformulaPDF

Feed rateformulafor milling

Precise – reliable – cost-effective. This is chamfering with the patented ChamferCut technology. As component-bound form cutter, ChamferCut allows the chamfering and deburring of gears in a continuous process. A consistently high chamfer quality is possible even in high-strength materials. ChamferCut stands for long tool life, short cycle times and a positive impact on subsequent processes. This reduces the component costs considerably.

Millingspeeds and feedsChart

I own a g0690 table saw and a 15" planer from them. They've been great. However, the smaller benchtop grizzly tools haven't impressed me at all.

initial cutter offset value and can be defined as either a DIAMETER or RADIUS ... Mill around outside of part using cutter compensation to offset the cutter,.

Feed rateformulafor turning

Online grocery shopping is available to customers in Springfield, several Springfield-area towns, Waynesville, Lebanon, West Plains, Clinton, Monett, and Aurora ...

As shown in the formula below, feed is â (cutting length per minute) ÷n (main axis spindle speed). (Cutting length per minute) ÷ (RPM) is the movement of the cutting edge during one work rotation.

Cutting speedformula

We are be happy to provide you with more information. Together, we develop ideas that make your production more efficient, innovative and profitable. Simply give us a call, send us an e-mail or use the contact form.

From now on internal gears can also be deburred and chamfered with cutting methods: The ChamferCut-IG (Internal Gear) makes this possible for users. For example, manufacturers of planetary gears can now benefit from all cost and quality advantages of the established proven ChamferCut process.

After starting with chamfer cutting on involute gears, today all process advantages can also be used with sprocket gears and worm gears, as well as with other gear types. With the newest tools, ChamferCut-CG and ChamferCut-IG, LMT Tools is introducing a new variant of ChamferCut in 2019, again delivering the highest quality results with low tool costs and extremely high productivity.

Need to build your own custom tool, select one of the blank templates below, and input all desired information. END MILL. END MILL DESIGNER.

The Machinability Rating of 304 Stainless Steel is 45% and The Machinability Rating of 316 Stainless Steel is 40% ... Run 303 Stainless at 70 SFM. Run 304 & 316 ...

When machining a 10 mm diameter shaft, lets says a 100 mm length is machined in 1 minute, at 1,000 RPM. This means that the cutting length per minute is 100 mm/min.

Cutting speed (when turning) is the peripheral speed of the work and the amount of insert movement in metres per minute. (Ï x Dm) of the formula below is the periphery of the work. The periphery x n (RPM) is millimeters the cutting edge moves on the periphery of the work in a minute. It is usually expressed in m/min. Divide by 1,000 to change to m from mm.

0086-813-8127573

0086-813-8127573