Titanium Materials for Sale - YINGGAO - titanium suppliers near me

⭐⭐⭐⭐⭐“I got my paint protect film done 2 weeks ago, and went back today for the windows tint. Ive been super satisfied with this company. They are professional, punctual and honest. Brian and his team responds promptly to messages and provides fair quotes. I am thoroughly impressed with both the quality of the work, and the fantastic service that I was given. Everyone I spoke to was extremely helpful. I couldn’t be happier with my PPF, and my windows. Highly highly recommended this place!” -Mason P. on Google

Soluble Oilcoolant

The Mist-Fit is Aeroex’s most popular option for lubricants and coolants for a reason. Its compact and modular design means it’s ready for deployment in any shop, and it’s easily configurable – for example, if you are using lubricants or coolants at different phases of your operation. A three-stage progressive filtration system uses mechanical elements to catch most of the product before finishing with a depth-loading fiber bed filter with MERV 15 rating to capture the hard-to-get oil mists that can cause problems in your shop. Our Canadian engineers have included a number of design features that promote drainage, limit filter changes, and prevent clogging. Mist-Fit is a great value choice for day-to-day machining with coolants and light oil lubricants. If you are using synthetic oils, we may recommend an optional four-stage HEPA filter to capture the sub-micron smoke and vapor particles. There is also an optional odor control for issues mentioned earlier.

Jun 7, 2022 — I've used a SDS rotary hammer to drill a couple of dozen 3/8 inch holes in concrete, and the bit barely looked worse for wear. Share.

Engine oil

Feb 27, 2019 — 1. Edge cracking. Edge cracks are longitudinal cracks within a few feet of one of the edges of the pavement. They can be caused by settlement ...

Sep 23, 2016 — Nickel is used as a catalyst for the hydrogenation of unsaturated compounds in several types of oils, changing substances from liquids to solids ...

Subscribe to our YouTube channel for more educational videos. So you’ve decided to invest in long-term paint protection for your car. That’s fantastic. But,

Cutting oil

water-basedcoolantfor machining

Welcome visitor you can login or create an account. My AccountShopping CartCheckout Catalog Search. 2 ...

Glock tungsten guide rod review. Gen 4 glock tungsten guide rod review. Glock 43x pure tungsten guide rod. Glock tungsten guide rod south africa.

Jul 13, 2024 — A fine thread leaves a larger root diameter on the male fastener, so it is stronger. A coarse thread will not pull out of a softer metal like aluminum as eaily.

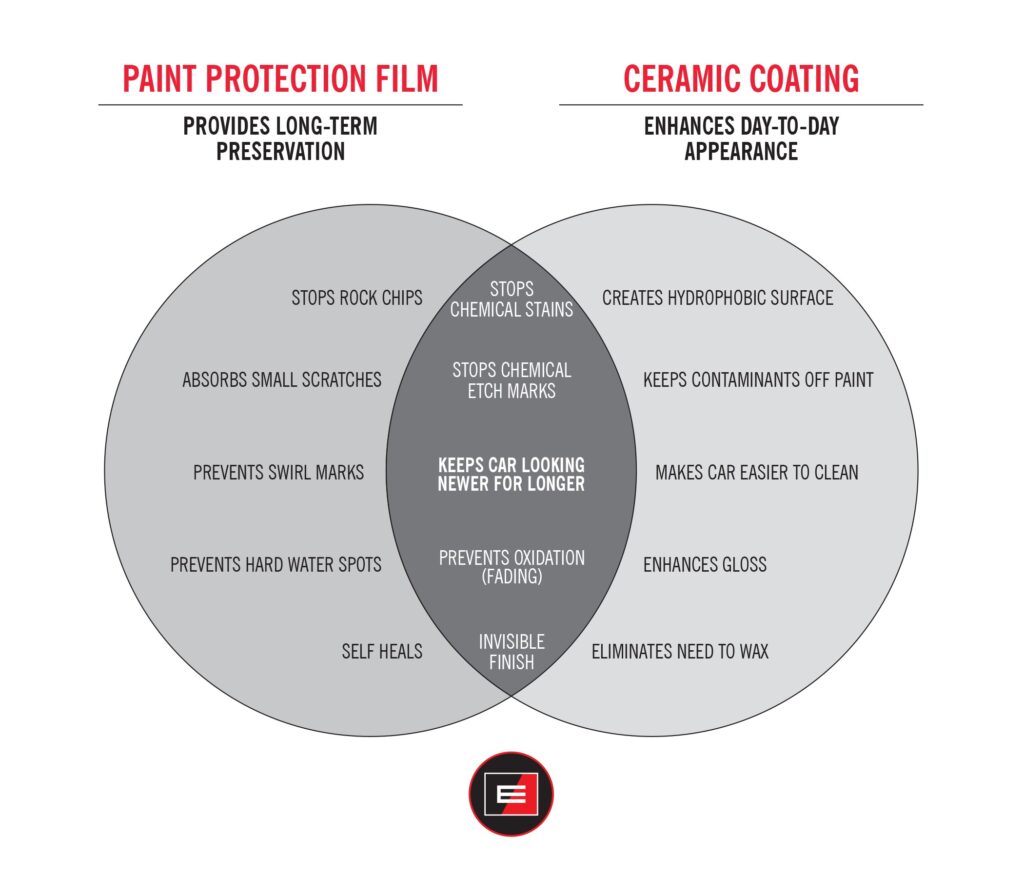

Together, the two products will preserve your car’s paint over the long-term, and enhance its appearance on a day-to-day basis.

Copyright © 2020 All Rights Reserved | Privacy Policy | Terms and ConditionsThis site is protected by reCAPTCHA and the GooglePrivacy Policy andTerms of Service apply.

Carbon fiber-reinforced polymers (CFRPs) have very good mechanical properties, such as extremely high tensile strength/weight ratios, tensile modulus/weight ...

Ceramic Coating is a liquid polymer that is applied to the exterior surfaces of a vehicle. After application, it chemically bonds with the vehicle’s factory paint, establishing a layer of protection and a hydrophobic surface. The hydrophobic properties of Ceramic Coating make it harder for contaminants to bond with your car’s paint. This has two main benefits for the car owner.

Here’s the good news. You don’t have to choose one or the other. They can both be applied to the same vehicle. The dynamic duo of Paint Protection Film and a Ceramic Coating is the ultimate form of invisible protection you can purchase for your car.

If you want to learn more about the history and technology behind Paint Protection Film, read our formal introduction to the product.

PPF vs Ceramic Coating Do you care about your car? Do you care about the physical appearance of your car’s exterior? If so, you’ve probably

Some coolants are compromised of oil diluted with water, which can lead to corrosion depending on the material of your machine or the product. The diluted nature of these coolants means they have less lubricity than their synthetic counterparts, limiting their use to lighter applications. Water-based coolants also have odor problems caused by bacteria depending on how they are used and stored. There are also synthetic lubricants, which are popular for precision machining but risk generating smoke (another air quality concern).

In the end, if you choose to purchase Paint Protection Film or a Ceramic Coating, you will be adding value to your vehicle.

Cutting and shaping metal through machining is an intense process that generates significant amounts of heat, creating implications for shops to perform these operations at scale. This is a well understood constraint on modern machining and there are strategies in place to deal with this. Given the amount of heat generated during the machining process, it’s very common to use oil lubricants or water-soluble coolants in your machining process to either reduce the heat generated or mitigate the impact of heat generated.

Your choice of lubricant versus coolant is likely to depend on your shop, the materials you are using, what operations you are running (e.g. drilling, milling, tapping, etc.), and how much heat is being generated. With each choice, it’s important to be aware of the dynamics of the fluids you are working with and how best to manage risks to your shop. Aeroex has been in the business of mist collection for more than twenty years and has studied the market to provide you with customized solutions that meet your performance expectations.

If you want to learn more, take a look at this Mercedes AMG GT-S we equipped with Paint Protection Film, or read about the specific benefits of applying a Ceramic Coating to your wheels.

At Aeroex, we will not push “one-size fits all” solutions on you. We value the time and patience of learning your specific challenges and getting consensus on a solution that is best for your situation. Oils and coolants present different challenges for machine operations and shop management, and we will work to fit right in with the corresponding oil mist collector that is right for you. To help us understand your needs, contact Aeroex today.

⭐⭐⭐⭐⭐ “Brian and his team have always done the highest quality work and have always exceeded my expectations. They care about their clients and have always made sure I was happy and they stand behind their work. It’s hard today to find companies that exhibit the integrity and professionalism that Brian and his team do. That’s the reason I use them and will continue to do so. They are the best around.” -Don F. Read more reviews on Google.

Paint Protection Film is applied first to the portions of your vehicle that will be most susceptible to rock chips or scratches from road debris. Since a Ceramic Coating does not protect against this kind of damage, it’s important to apply Paint Protection Film to these areas. This often includes the front bumper, hood, fenders, side mirrors, rocker panels, and rear wheel arch.

For each operation, a shop will choose which fluids make the most sense given the type of machining, material type, past experience, etc. Each choice of coolant or lubricant will have different outcomes for your process, and for the safety and quality risks posed by mists in your shop when these fluids are used. Aeroex understands the range of fluids machining shops use and considers the properties of each when recommending a mist collector or industrial air purification solution. Here are a few things to consider:

Do you care about your car? Do you care about the physical appearance of your car’s exterior? If so, you’ve probably done some research about the products available for protecting and preserving your car’s paint, and you’ve probably come across some information about two different products: Paint Protection Film (PPF or Clear Bra, such as XPEL Ultimate), and Ceramic Coatings (such as Opti-Coat Pro+).

Types of cutting fluids PDF

All vehicles pictured on this site were served by Exclusive Paint Protection – Detailing, PPF, Ceramic Coating & Window Tinting.

The standard clearance is quite large. You can use an end cutting milling cutter, grind a drill to about a 170deg point or ideally make a D bit to get a flat ...

Oil lubricants come in a range of viscosities ranging from low viscosity to high viscosity. The goal of each is the same – to reduce friction and heat generation during machining. A fluid that is too thick can make your machines work harder, leading to wear and tear because of undue effort. However, if the oil is too thin, it may not be sufficient enough to prevent friction and create lubrication. In any machine operation, a balancing act is needed to select the right lubricant for the job.

Oils are relatively viscous fluids, meaning that the friction between their particles is greater than the surfaces they interact with. This is what makes oils “slippery”, making them an excellent lubricant for machining. By reducing friction between surfaces and workpieces, less heat is generated during machining. Note that if any heat is generated in spite of a lubricant, the oil will not reduce the heat. Lubricant can be applied during machining or with a coating layer on the tool itself.

⭐⭐⭐⭐⭐“I had paint protection and window tint installed on my car from Exclusive Detail. I could not be happier with the results. From my first interaction with Brian over the phone through to picking up my car it was A+ service. Brian answered every question that I had thoroughly and went over any pros and cons of the options that I had available to me. I receive compliments on the look of my car every where that I go and they want to touch my car (grrr..). I would not hesitate to recommend Exclusive Detail to anyone looking to get any of the services they offer given the results that I’ve seen with my car.” -Danny B. on Google

Coolants are the second major category of fluids to use in machining that will help you manage potential heat generation and can keep your machines operating. There are a number of differences when compared to lubricants that add considerations for selecting machining fluids.

Enginecoolant

Despite these similarities, Paint Protection Films and Ceramic Coatings do have significant differences and serve different purposes.

⭐⭐⭐⭐⭐“Brian and his entire staff are very knowledgeable when it comes to protecting your vehicle. They focus on attention to detail, as part of their craftsmanship. On top of the superb job that they provided, on my car, Brian made suggestions that I hadn’t even thought about. He kept me informed throughout the entire process with photos and updates. This was my second go around for paint protection on my car, and the service was like night and day compared to the previous shop. I HIGHLY recommend Exclusive Detail to any potential customer looking for quality, honesty and top notch professional service. l will bring all of my future vehicles to Exclusive Detail for that seal of approval. BEST SHOP, HANDS DOWN!” -Carlos C. on Google

Are you ready to drive protected? If so, contact us today to schedule an appointment or ask any questions you may have about how you can protect your car’s paint.

Tapping with the roll tap initially selected. ①. When the Go plug gauge measures tight, try tapping again with a tap with a larger thread.

Coolants differ from oil lubricants in that they take heat away only after it is generated, rather than preventing it in the first place like oils would. While heat generation occurs, the coolants continually keep the cutting zone at a lower temperature. The main benefit of a coolant is that it does not risk ignition, which allows more opportunities to scale up your machining operations without risk of fire hazards or added resources for monitoring.

As you can see, both products serve the purpose of keeping your car looking newer for longer by protecting and preserving your car’s paint.

Difference between coolant and lubricantautomotive

Jan 21, 2011 — A fine hack saw blade or a diamond cut off wheel but tape both sides of your cut and glasses with dust mask would be good.

What’s the difference between these two products? What will they accomplish for your car? And what will be the best solution for protecting your car’s paint?

The ARO Series incorporates all of the design and quality of life features known and loved in the Mist-Fit. The ARO Series has added capacity for heavy machinery using thick oils that need near-constant runtimes without disruptions for filter changes, maintenance, or clogging. The ARO is the premium choice for the virtual elimination of smoke and mist at scale, delivering up to 4000 cfm and potentially accommodating multiple machines simultaneously.

In addition to this common central aim, the two products have some overlapping performance features. Specifically, both products help reduce damage from UV exposure and acidic contaminants.

Types ofcoolantused in machining

Perhaps most importantly, oil is a combustible and volatile fluid. If for some reason too much heat is generated and the flashpoint is reached, lubricants can ignite. So, any machining operation and oil collection solution needs to account for these fire prevention and safety considerations. Oil lubricants can also lead to smoke along with volatilized mist, meaning that your air purification system will need to be able to capture these particles.

Once the most vulnerable areas are protected with Paint Protection Film, your whole car receives a Ceramic Coating. The coating will bond to both the vehicle’s factory paint and the film that has already been applied. When applied on top of film, coating will provide an additional layer of protection from chemical etching and stains. It will also help keep the film clean and free from contaminants, which will lengthen the life of the film.

Everywhere else on the vehicle, whether protected by film or not, the Ceramic Coating will thwart oxidation and chemical etch marks or stains. Moreover, the hydrophobic surface will make it harder for contaminants to bond to the vehicle, keeping the paint cleaner and making it easier to wash. The smooth surface of the Ceramic Coating will also enhance the gloss of your vehicle’s factory paint.

Paint Protection Film is a transparent, urethane material that can be applied to any exterior painted surface on your vehicle. In short, automotive Paint Protection Film preserves the quality of your car’s paint by reducing the risk of multiple kinds of damage, such as…

So if your aim is to protect and preserve your car’s paint so that it looks stunning every day your drive it, a combination of Paint Protection Film and Ceramic Coating may be the best fit for you.

DBAs: “Exclusive Paint Protection – Charlotte Detailing, PPF, Ceramic Coating & Window Tinting” and “Exclusive Paint Protection – Lake Norman Detailing, PPF, Ceramic Coating & Window Tinting”

0086-813-8127573

0086-813-8127573