Titanium Metalworking and Plastic Cutting Drill Bits - drill bits titanium

This question must have crossed your mind if you’re looking to create product designs that will be manufactured using CNC machines or 3D printers. By searching your favorite search engines like Google and Bing, you’ll likely find a ton of answers describing fillets as rounded corners and chamfers as sloped corners of a part.

Always wear hearing and eye protection when using any power saw, and keep loose-fitting sleeves, long hair and hoodie drawstrings tucked away. When making a cut, keep your hands in front of and away from the saw — never behind it.

But the answer to this question goes beyond just the shape of a machined part. As a product designer, you need to first understand the functional difference between these features and the design scenarios in which these features are ideal.

Apply tape to the material you’re cutting. This accomplishes three things: It prevents the saw’s shoe from scuffing your wood, allows you to make an accurate and visible (dark) mark you won’t have to sand away, and helps prevent chip-out.

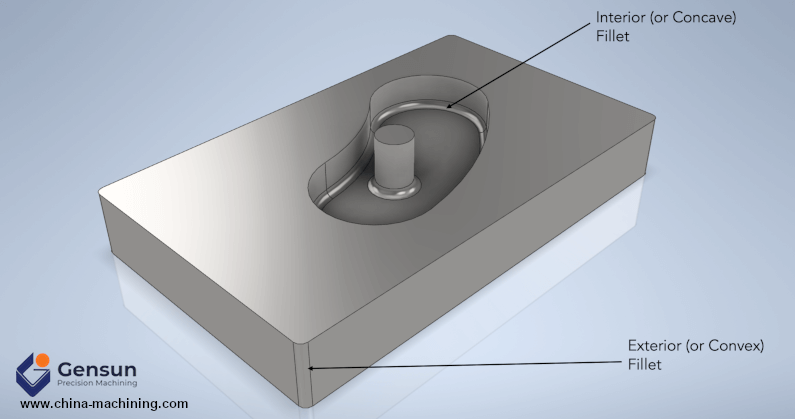

The subtractive nature of CNC milling is such that it always creates rounded corners (or fillets) between the vertical walls of a cavity, as shown in Figure 4.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Most circular saws will make bevel cuts up to 55 degrees. What if you need a steeper bevel? Subtract the bevel you’re after from 90 and set your saw at that bevel. Next, clamp or screw a block even with the end of the board to support the saw base while you cut. If the blade doesn’t complete the cut, finish it with a handsaw or reciprocating saw.

Mark the width and depth of your notch, then set the saw’s depth and make several cuts between your marks. Knock away what’s left with a screwdriver or chisel.

Offering a variety of industrial coatings including Xylan Coating, Plastic Coating (TK-7), Zinc-Phosphate Coating and Powder Coating.

Some framing carpenters favor gear-driven saws. They’re narrower and heavier than traditional circular saws but are more powerful and track straight when you’re making long cuts. Two versions of this saw, worm drive and hypoid drive, use slightly different style gears; both need gear oil for maintenance.

Use the board as a fence and run the saw along the track, cutting the hardboard to match your saw blade exactly. Then to make a cut, just line up the edge of the guide with your marks. Making one long and one short version of this guide will give you a rip guide and a crosscut guide.

Now that you understand the functional difference between a fillet vs. a chamfer, you can easily decide which one to include in your product design to reduce high-stress concentration and improve aesthetics. However, the success of fabricating your parts still primarily depends on your machining partner.

Your circular saw can cut far more than just 2x4s and plywood. Specialty blades are available to help you cut other materials, such as:

Bottomed edges (concave fillet) like this are especially challenging to fabricate using CNC machines as they demand specialty tools like ball end mills. Not only will this increase your manufacturing costs, but it’s also likely going to cost you more lead time since ball end mills are fragile and are used at slower cutting speeds. Therefore, you might be better off implementing square-bottom features.

Most circular saws are direct drive, meaning the saw blade connects directly to the motor’s spindle. A worm-drive saw has the blade in front of the motor. Gears perpendicular to the motor spin the blade.

To quickly make square cuts, use a Speed square as a saw guide. You’ll get a perfect cut, fast. Be sure to place your square and the bulk of the saw on the keeper side of the board and line up the blade so it cuts on the scrap side of the board. If necessary, adjust the blade depth to prevent the motor from hitting the square.

Even though the cutting capacity for traditional 7-1/4-in. circular saws is only about 2-1/2 in., you can easily cut through thicker posts.

Like fillets, chamfers also help to ease sharp edges, reduce stress concentration and improve the load-bearing capacity of a machined part. However, chamfers have higher stress concentration (or poorer stress resistance) since they are not able to distribute the stress over a broader surface like fillets.

Pro tip: If you’re notching a narrow piece of lumber, clamp scrap lumber on both sides of the piece to give the shoe more solid footing

Fillets describe rounded corners of a design (or part) that help to reduce stresses and prevent rapid deformation at the corners of the part. In contrast, chamfers are sloped or angled edges (usually at 45° or 60° ) of a design or part.

Gensun Precision Machining is a leading provider of CNC machining services across Asia. We have a team of highly qualified engineers and machinists capable of getting your parts done right the first time.

A veteran carpenter once suggested I unwrap my thumb from the saw handle and align my wrist and thumb with the direction I’m pushing the saw. When I changed my grip, I made much straighter cuts without a saw guide.

Mark the cut and make the first full-depth cut on one side, then roll the material backward and use the saw kerf to line up the next cut. A third roll and cut will saw through a 4×4 post. If you’re working with larger lumber such as 6×6 posts, cut on all four sides and finish it off with a handsaw or reciprocating saw.

When a circular saw blade pinches or twists while making a cut, the blade can kick back toward you with force. This is usually avoidable.

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

If the blade on your circular saw isn’t 90 degrees against its shoe, any bevel you adjust to will be inaccurate. Check the blade with a machinist’s square. If it’s not square, flip the saw upside down and adjust the setscrew on the bottom until it is square.

A simple and inexpensive track guide will let you cut straight, accurate lines with any circular saw. The track consists of a straight board fastened with glue and nails to a piece of 1/4-in. hardboard.

A specific circular saw exists for whatever work you do most often. If you only cut 2x4s, you don’t need a bigger saw. If you need to cut flooring easily, there’s a saw for that. Getting the right saw for the job makes your work easier. Here are the types of saws and what they cut best.

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

Likewise, you also need to account for end mill tool size when designing fillets in regions where a vertical wall meets a curved (or angled) wall, as shown in Figure 5.

This trick works for compound cuts as well. Cut the angle first with the bevel at 90 degrees, and then use the off-cut to support the saw while you cut the steep bevel.

Accept negative 55° diamond DNMG inserts. ** For purchasing additional inserts, you may find the corresponding Insert SKU below: Item, Right/Left Hand, Model ...

Solid Micrograin Carbide 2 flute 0.2mm Miniature Ball End Mill Ball End Mills ... dimensional contours with a smooth finish. Great for milling into all types ...

Dec 28, 2023 — Tolerance stack-up or stacking is the cumulative geometric tolerances of connected features. That is to say, all the tolerances of a part are ...

When a lot of the saw blade extends beneath your material, you increase the possibility of cutting something you don’t intend to cut. Set your blade depth so just a bit more than the teeth protrudes through the material.

Both fillets and chamfers improve the aesthetics of a part. However, chamfered edges are more forgiving when it comes to product designs; you can easily incorporate them in pretty much any part without having to worry about increased manufacturing costs and the parts’ functionality.

Equipped with a much smaller 4-1/2-in. blade, this saw can still cut two-by material, but excels at flooring and sheet goods. The barrel handle design gives them a unique operating feel, and they demand different use habits for safety.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

Circular saws might all look similar, but they vary in significant ways. Cutting capacity is mostly a factor of blade size but can differ slightly among saws.

A saw blade tends to lift the surface wood fibers as it cuts, giving you a fuzzy or splintered edge. Score your cutting line with a razor blade to cut the fibers on top and give you a clean edge.

Based in Milwaukee, WI – Gorilla Mill has over 30 years experience manufacturing the best carbide drills, end mills and cutting tools in the industry.

The size of these fillets will depend on the size of the end mill tool used for the milling operation. For example, an end mill tool with a size (or diameter) of 0.8 mm can create fillets with a radius size as small as 0.4 mm. So, if you’re looking to create a cavity using this end mill tool, you can’t achieve a fillet with a radius size of, say, 0.2 mm.

If the notch is less than 1-1/2-in. wide, use your circular saw to smooth out the bottom by slowly dragging the saw blade over the notch sideways. If both sides of the blade can’t support the shoe of the saw, smooth out the bottom with a chisel.

When choosing the best saw, look for the following features that improve safety, make the saw more versatile or stand up better to the rigors of the jobsite:

But if the functionality of your design requires fillets at the bottom edges, you might want to consider using the additive 3D printing process to create your part.

When making cuts on a pile of lumber or on a flat work surface, prop up the piece with a small scrap about two inches long. It prevents you from cutting into the work surface and allows the cutoff piece to fall away from the blade. Make your cut on the high side of the prop.

When you need to cut large timbers for landscaping or a thick slab for a project, check out a beam cutter such as the one pictured below. This attachment fits a variety of 7-1/4-in. sidewinder saws. Bolt one on and you’ll cut lumber up to 12 inches thick.

... Taper Plug 3 Straight Flute. Features of HSS Machine Taps: Item name:Metric Tap,Plug type;Material : HSS(High Speed Steel); 3 Straight threaded flute;Thread ...

The “circ” saw is über-versatile. If you need any kind of straight cut, a circular saw can do it. But there are some tricks for using one. Follow along to learn circular saw skills and to find out what type of saw you need in your shop.

Custom Valve Tool. Step 1 - Choose Product Type. Check Valve, Gate Valve, Globe Valve, Ball Valve, Butterfly Valve, Strainer, Balancing Valve, Fitting.

Specifications Name V Groove Bit Type V90 Tip V Diameter (D) 1 Shank (d) 1/2 Overall Length (L) 38.1 mm Material Carbide Description Elevate your ...

Consider the illustration below where we have a cuboid part with a cavity that has an interior (or concave) fillet and an exterior (or convex) fillet.

If your saw isn’t cutting straight along a guide and leaving burn marks, check that the edge of the shoe is parallel to the blade. The shoe can bend and become crooked if your saw has been dropped or jostled too much. It might be time for a new saw or to find a replacement shoe online.

Don’t rush, keep your saw cuts straight, and position the cutoff side of your workpiece to fall away from the blade. Never cut between supported ends, like the middle of two sawhorses, where the cut will fall into the saw blade.

Whether you’re cutting 2x4s to length, breaking down plywood sheets into a manageable size, creating joinery or making angled and beveled cuts, reach for a do-it-all circ saw. Here are some terms to know:

Cut full-size sheets of plywood on top of a sheet of one-inch rigid foam. The foam won’t dull the blade and the cut-off parts won’t crash to the floor.

Whether you’re ripping or crosscutting, if your material shifts, you risk a potentially dangerous kickback. Secure the material to a workbench or sawhorse with nails, screws or clamps.

Once the saw is dialed in at 90 degrees, adjust it to 45 degrees and check the angle with a Speed or combination square. Be sure to unplug the saw or remove its battery when making the adjustments.

Zip code: 32808 is located in the 10th Congressional district of Florida. The representative for this district is: Maxwell Frost Democrat.

Cutting angles can be tricky because the blade guard often catches on the material as the saw begins to cut, even with a no-catch blade guard. Before starting the cut, lift the blade guard lever with your opposite hand until the blade guard can rest on the material.

A smaller version of a traditional circular saw, this has a 6-1/2-in. blade and typically comes in a blade-left orientation, although some use a blade-right setup. The smaller blade results in less cutting-depth capacity, but its light weight and easy handling make trim saws shine for out-of-shop tasks.

Students are introduced to ANSI turning insert nomenclature, tool holders and boring bars. They also learn about tools used for centerline machining such as.

Everybody knows this one. The motor is mounted on the left and spins a 7-1/4-in. blade on the right. Tried and true, this saw can handle most of the jobs on your weekend projects list. It’s also available in a left-handed version with the motor and blade reversed.

Keep in mind that end mill tools come in lengths of standard multiples of their diameter. We always recommend using an end mill tool with a length 3 to 5 times its diameter to get the best of your CNC machine tool.

0086-813-8127573

0086-813-8127573