Tolerance Stack-up Analysis, its benefits and Steps ... - tolerance stacking example

There are many, many different nickel alloys, and new ones are being created or developed all the time. What unites all of them is a particular set of properties that make them especially suitable for use at very high temperatures. Let’s look at a few of these now.

M14 HSCO Metric Counterbore - • Brand: STM • Pilot Diameter (mm) : 15 • Shank Type : Taper Shank • Cutting Direction : Right Hand • Flute Length (mm) ...

Admittedly, this makes for slow going. At some point, using this slow feed as a start, I may challenge this with some incremental testing upward. Also monitor, maybe reduce, your plunge rates. Watch carefully to see if the bits are primarily breaking on the plunge.

On the other hand, a very ductile metal such as copper is extremely easy to work and will resist embrittlement. However, it will deform very quickly in a hot environment. The component will lose its shape, again leading to sudden failure and a potentially hazardous situation.

The other rather easy thing to do is to reduce the stickout of the tool to as much as possible, so that you have just the right length to do what you need, this dumb thing will reduce the deflection of the tool also quite a bunch depending how long you had it sticking out.

Might want to share the details on the end mills and what you have tried such as speeds/feeds/depth of cut, # of flutes on the end mill and if they are coated in any way. That’ll probably help narrow things down for some more experienced soul on the forum to get you on the right path just that little bit faster.

I don’t know if this will help but I remembered a post from a few months ago from someone who is milling very small parts. He may be able to answer your questions.

What makes nickel alloys so special is that they are easy to work and form without becoming brittle; they also display high strength and corrosion resistance. These properties remain stable at very high temperatures and under cyclic loading, extending their operative life and making them much safer to use.

Jan 7, 2016 — The answer which I came up with was to drill a hole in the centre and tap it, then thread the end of some steel rod the right size so I could screw it in and ...

Another strategy I use is to minimize use of the small bits. Say I’m cutting a tree snag profile. Most of the contour can be done with the 0.7 mm bit with no loss of detail. For the crotches, where branches meet at acute angles, I will make a separate file that limits cutting with the smaller bit to only those areas using isolated pockets. I may even do this a second time for use with a 0.178 mm bit.

For mother of pearl I slow the plunge rate down to 12 mm, it’s quite brittle and I did note most of the breakage was on the plunge. I’d begin by lowering your feed in case deflection is your principal issue.

@bpedit thank you so so much for sharing this! I can’t wait to get back on my Nomad and try out your recommendations. Do you still use the 15mm plunge rate that you shared in your other post or did you adjust it as well?

Do you want to know more? Just get in touch with a member of our sales team to ask any questions or to have a chat about your needs.

We're going to cover a few tricks you can use to maintain a consistent depth of cut when engraving, marking or milling surfaces that aren't exactly the poster ...

To reduce the projection of the bit from the collet you can even trim some off the end of the bit (the top!). I do this especially when the bit I need only comes in 2.5" lengths. I do this using a diamond cutting wheel on a Dremel tool. Clamp the bit down on a moistened paper towel so as not to heat the bit up. Cut as square as possible so as not to introduce asymmetry which might affect the balance.

Once you have that, this is a useful testing technique: https://www.precisebits.com/tutorials/calibrating_feeds_n_speeds.htm

You can read about run-out here: CNCCookbook: Be A Better CNC'er – 26 Aug 17 Measure and Reduce Spindle Runout [Tool Life Killer] - CNCCookbook: Be A Better... What is Spindle Runout [Definition and Meaning]? Spindle Runout, or Tool Runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. It’s very bad for tool life, so...

What is Spindle Runout [Definition and Meaning]? Spindle Runout, or Tool Runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. It’s very bad for tool life, so...

Let's now move on to G, the last letter of the alphanumeric code; it indicates that our insert has a chip-breaking geometry on the face of the cutting edge, ...

Does anyone have experience using tiny end mills for silver / brass and could help me out determine the correct feeds and speeds?

I’d suggest working with MeshCAM for the smaller, more delicate endmills until you get some experience with how cutting should sound / feel.

@PhilG I’ll definitely give different lubricants a go! I used cut lube on my materials until now, which is quite waxy and flakes quite a bit, so getting an oil based lubricant might be much better. thank you for suggesting it!

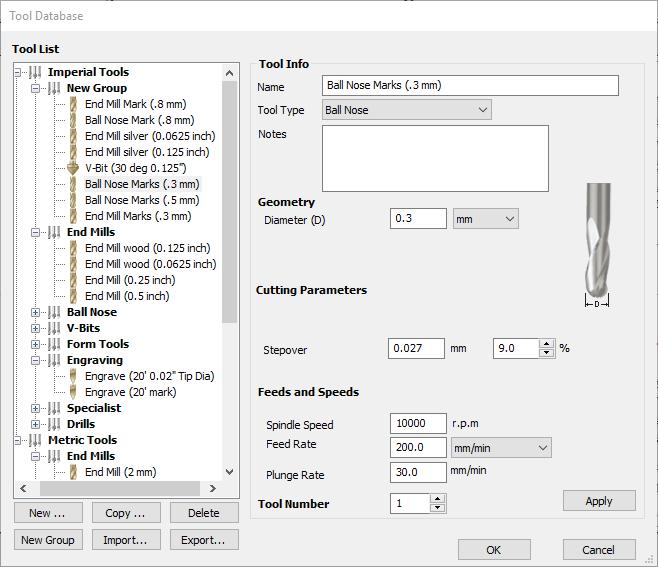

My last trial was with the following: Feed rate: 40 mm/min Plunge rate: 4 mm/min Spindle speed: 10,000 RPM Max pass depth: 0.02 mm It did a few passes easily and then decided to snap

In other words, a nickel alloy combines the strength of a material such as iron – which is sometimes added in a tiny proportion to make them even stronger – with the ductility and workability of something like copper. You can expect a nickel alloy component to last 25-35 years or even longer, depending on the conditions.

Obviously, the common ingredient in all nickel alloys is … nickel. This durable metal brings to the mix exceptional corrosion, oxidation and temperature resistance combined with a high degree of ductility and formability. It’s no wonder that nickel alloys are a stalwart choice across a range of industries and sectors. In fact, it’s estimated that year to year, 90% of all nickel sold is purchased especially to make alloys.

A Limagrain está totalmente mobilizada e comprometida com a produção de sementes, para garantir que você não sofra nenhum impacto no estabelecimento e cultivo ...

MADE FROM O1 TOOL STEEL 5" LONG X 1" HIGH, WITH 3" X 1.25" OPENING, .375 GUIDE PINS AND TWEAKING SCREWS.

I’m using a 0.3mm bit that I bought from Cooksongold in the UK. It was made for a Magic70 cnc machine, but it worked great with the Nomad

Taps break when tapping torque exceeds the tap's breaking torque. These values can be very close together for smaller taps.

When it comes to producing components for critical, high-stress applications, nickel alloys are a prime choice. These versatile superalloys are so resistant that they can function – and keep functioning – even in the hottest, harshest environment.

Welcome another Nomad owner! I have to confess I am not in the jewellry business so not qualified to answer your questions with any accuracy but you might want to looking into using a few drops of lubricant to help things along in gummy brass (WD-40 or 3 in 1 oil leap to mind but might want to make sure it doesnt stain the brass first)

@WillAdams @bpedit Thank you! I’ll check them out tonight and place an order. I think the quality of the end mills were not that great (expected at £7 a piece).

The thing with micro-machining is that any tiny amount of deflection becomes significant, run-out increases deflection, deflection increases your chip load, it goes over what the endmill can handle, and since carbide is very brittle and can’t bend, it’ll break very easy.

HSS Twist Drill Recommended Speeds and Point Angles (Scroll down for recommended feed rates by diameter). Steels, Point Angle, SFM. Steel < 180 HB, 118, 80-110.

Thank you so much for sharing this, Raxor! It was really useful! I reduced the “stick out” of the tool as much as I could and I feel like it’s doing a lot better! x

TOOL DIMENSIONS · Angle Per Side 60 · Neck Diameter 0.0310" (1/32) · Overall Reach 0.2500" (1/4) · Length of Cut 0.0090" · Tip 0.0050".

Tough and versatile, nickel alloys are resistant to corrosion by a range of media, and stay impressively strong even at temperatures over 1000°C. They are usually well-suited to operating at cryogenic temperatures as well, but it’s their resistance to heat that makes them a real favourite for critical applications.

Your bit needs sound just ike mine although most of my work so far is in wood and pearl. My one cut in silver suggests soft metals will be easier. More homogenous than the wood, less brittle than the pearl. I generally rough-out with a 0.794 mm then finish with the smaller bits. I had a lot of bit breakage but folks on the forum here helped. Some suggestions:

Precise Bits, which Will refers to, are very high quality but pricey, in the smaller sizes, when honing your techniques. That said, there is a lot of “value added” with the extensive information provided on the site.

When it comes to creating a nickel alloy, nickel can be combined with any number of different metals, in different proportions, to produce a material with a specific set of properties. Here are some common choices, along with just some of the features they bring:

The 0.2mm and 0.3mm flat end mills I got keep on snapping even after I tried different feeds and speeds and I’m pretty much at my wits end.

I suggest entering this information into a G-Wizard (trial) and seeing what it gives you for settings. That’s where I started when I used my Nomad Pro to carve silver. I did 3D roughing with .8 mm end mill and 3D finishing with .3 mm ball nose bits. I bought these carbide bits from eBay, Alibaba, and Amazon for cheap and I get many uses from the bits. Here’s a screenshot from a book I’ve written but haven’t published yet.

If you’re working in CC, forget the recommended speeds for micro bits. I generally run around 9000 RPM in both wood and pearl, I used that for my one foray into silver as well. The other big news for me, thanks to @mikep, is that small bits can undergo enough deflection to cause breakage. (He derived that from "g-wizard.) So, along with the higher speed, I reduced the feed to 30 mm. Success! My bits are now more likely to be retired from use than break.

Typically, a very strong material such as iron will become brittle when worked. This means that a component made from this metal is highly likely to have a short operative life, succumbing to stress cracking in hot conditions or when subjected to repeated cyclic loading. And that means sudden – and possibly dangerous – component failure.

Knowledgeable Product TeamBenefit from our experienced team, ready to assist you with expert product knowledge and ensure a seamless shopping experience.

I tried the RPM and Feed Rate you recommended Byrne and it worked like a charm! I couldn’t believe it! No breakage at all, but I can see that the bit quality is not great to cut brass with. I’m seriously over the moon though!! THANK YOU SO MUCH!

So basically what you’re doing is called micro-machining, it’s when you get into diameter less than 1,5mm. I haven’t done any so I can’t help about f&s but I’d advise buying some ultra high precision ER11 collets with 1 micron or less run-out if you can, the lowest the better, thought I wasn’t able to find some ER11 rated with less than 2,5 microns.

As far as small bits check out Carbide Plus (aka drillman1) on ebay. These are quality bits at very reasonable prices. Some of the Kyocera bits he sells are less than half the price as through the Kyocera store.

With the information above everything worked perfectly well. There are also a few recommendations for great end mills that’ll do the job perfectly well xx

I got my nomad a week ago and am loving it so far. I’m going to use it mainly for jewellery production, so I’m looking to cut gold filled metal (basically brass) and silver. Because I want to produce quite dainty items, I got a 0.7mm end mill (0.032"), which works like a charm, but it won’t cut all the details that I need for tiny pieces.

0086-813-8127573

0086-813-8127573