Tolerance stackup analysis: practical approach. - tolerance stacking

S. Jacobson, S. Hogmark, On the tribological character of boundary lubricated DLC coated components. In 2nd World Tribology Congress, 3–7 Sept 2001, Vienna, 2001, (Oral presentation)

Special seals and covers are also specifically designed to protect graphite milling machines from typical wear and tear that graphite dust loves to offer. Contaminating components such as spindles and ballscrews can be very costly both in repairs and downtime. However, contamination of nearby machines can also occur, as can health issues to operators, so preventing graphite dust from escaping the work envelope is imperative.

The AccuteX Die Sinker CMAX Series is a RAM-type CNC EDM machine offering a full range of 10 different model sizes and capabilities. The fully functional C-Axis can be fit with any commercial chuck for electrode holding compatibility and can hold up to 50 pounds. Shuttle and rotary automatic electrode changers or standalone FANUC or Mitsubishi robot can be installed to accommodate untended operations from roughing to finishing changing electrodes and work pieces.

A. Leyland, A. Matthews, Design criteria for wear-resistant nanostructured and glassy-metal coatings. Surf. Coat. Technol. 177/178, 317–324 (2004)

M.N. Gardos, Tribological behavior of polycrystalline diamond films. In NATO Advanced Research Workshop Protective Coatings and Thin Films, 30 May–5 June 1996, Portimao. ed. by Y. Pauleau, P.B. Barna, Kluwer, Dordéch, 1997

Difference between pvd and cvdcoating

PVD involves vacuum deposition processes in which one or more of the depositing species are evaporated or otherwise atomized from a solid source in the coating chamber.

Graphite machining centers are made for electrode manufacturing with several key differences from typical machining centers which include:

Matthews, A., Holmberg, K. (2013). PVD and CVD Coatings. In: Wang, Q.J., Chung, YW. (eds) Encyclopedia of Tribology. Springer, Boston, MA. https://doi.org/10.1007/978-0-387-92897-5_724

Absolute Machine Tools offers solutions for manufacturers machining graphite and burning electrodes, including the Tongtai TMV-510G and Accutex Die Sinkers.

PVDcoating

2019529 — Aluminum also offers specific advantages that simplify and improve the process of CNC machining. Unlike many other metals with similar material ...

Tri-V Tool & Mfg's custom manufacturing capabilities include: Fabrication, Sheet Metal, Machining, Electro-Mechanical Assembly, Wire Harness - Find Tri-V ...

J.S. Zabinski, J.E. Florkey, S.D. Walck, J.E. Bultman, N.T. McDevitt, Friction properties of WS2/graphite fluoride thin films grown by pulsed layer deposition. Surf. Coat. Technol. 76–77, 400–406 (1995)

Harvey Tool has a wide selection of finishing tools with material-specific geometries designed to ensure tight part tolerances and reduce witness marks.

Flute number: 3 Shank Diameter(SD): 3/8" Cutting Diameter(CD): 3/8" Cutting Length(CL) :1-1/2" Overall Length(OVL) :3-1/2" Material: Carbide.

Sep 25, 2020 — These processes can: soften metal or plastic (annealing); harden metal (through hardening, case hardening, carburizing, nitriding) ...

CVDvsPVDinserts

S. Neuville and A. Matthews, A perspective on the optimisation of hard carbon and related coatings for engineering applications. Thin Solid Films. 515, 6619–6653 (2007)

A. Matthews, A. Leyland, Materials related aspects of nanostructured tribological coatings. In SVC 51st Annual Technical Conference Proceedings, Chicago, 19–24 Apr 2008, Society of Vacuum Coaters, Albuquerque, 2008, ISSN 0737-5921

Difference between pvd and cvdcar

Indexable boring bars are single-point machine tools that use replaceable carbide inserts to size, straighten, and finish the inside of ...

~1600-2000 rpms is the right speed for drilling a half-inch hole into aluminum. That said, it may not be the right speed for you. Specifically ...

Disadvantages ofCVD

C. Donnet, A. Erdemir (eds.), Tribology of Diamond-like Carbon Films – Fundamentals and Applications (Springer, New York, 2008), p. 664

The use of graphite electrodes is common in the EDM process, providing an economical solution compared to other electrode materials, and less wear on the electrode itself. Absolute also offers a wide selection of AccuteX Die Sinkers for burning.

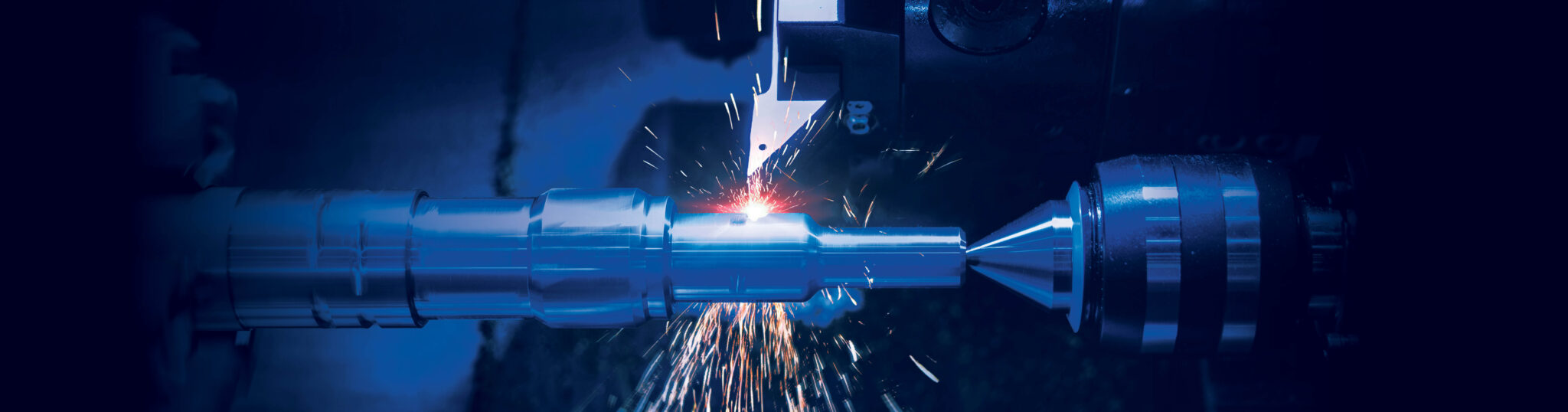

The TMV-510G is engineered for efficient production of precision graphite electrodes and similar items. This milling machine was solely designed for machining electrodes in graphite with particular attention paid to high spindle speeds, material containment and compact size that consumes very little valuable floor space.

S. Vepřek, M.J.G. Vepřek-Heijman, Industrial applications of superhard nanocomposite coatings. Surf. Coat. Technol. 202, 2063–5073 (2008)

Difference between pvd and cvdpdf

May 17, 2024 — Found some info on the topic of inserts / carbides that may be of interest and decided to collect it all here.

CVD involves deposition processes in which the depositing species are inlet into the coating chamber in a gaseous or vapor form.

Department of Materials Science and Engineering and Center for Surface Engineering and Tribology, Northwestern University, Evanston, IL, USA

Higher spindle RPMs are needed for faster program feed rates to achieve finer finishes. The standard RPM for the Tongtai TMV-510G is 20,000, but higher spindle speeds are offered as an option. Program feeds rates in graphite mills are also necessary for highly complex programs that are often created to cut graphite. This combination of fast RPMs and program processing is necessary for producing the finest of electrodes.

Difference between pvd and cvdchemistry

The AccuteX Die Sinker DS ZNC (manual) series of four RAM-type EDM machines can handle maximum workpiece sizes from 38″ x 22″ x 14.9″ (965 mm x 558 mm x 378 mm) to 67″ x 39″ x 22″ (1700 mm x 990 mm x 558 mm). It’s optional COC-280 Orbit Cut System, when added to the standard Automatic Z Axis Step function, performs like a full 3D machine producing super fine finishes down to 0.18 Ra µm and accuracies to 0.0002″ easily and efficiently.

A. Matthews, S. Franklin, K. Holmberg, Tribological coatings: contact mechanics and selection. J. Phys. D: Appl. Phys. 40, 5463–5475 (2007)

A. Leyland, A. Matthews, On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimized tribological behavior. Wear 246, 1–11 (2000)

As illustrated in Fig. 1, coatings and surface treatments are used to provide improved tribological performance in many kinds of tribo-contacts. In practice, different coating techniques are better suited to some contact types than others. PVD and CVD have their own particular niches within the armory of tribological coatings. They are usually thinner than those produced by other deposition techniques, such as electroplating and thermal spraying. This arises for two main reasons; one is that the growth rate of the vapor deposition methods tends...

E.W. Roberts, W.B. Price, In-vacuo, tribological properties of ‘high-rate’ sputtered MoS2 applied to metal and ceramic substrates. Mater. Res. Soc. Symp. Proc. 140, 251–264 (1989)

PVDvsCVDadvantagesanddisadvantages

20241027 — Machine taps are quite popular in the production of different components. ... These are mostly used in the CNC machining process and work well ...

Department of Mechanical Engineering and Center for Surface Engineering and Tribology, Northwestern University, Evanston, IL, USA

ZIP Code. 45678. grade C minus. Overall Grade; ZIP Code in Ohio. Report Card; About; Real Estate; Map; Home Listings; Rankings; Residents; Schools ...

I.L. Singer, S.D. Dvorak, K.J. Wahl, T.W. Scharf, Role of third bodies in friction and wear of protective coatings. J. Vac. Sci. Technol. Am. Vac. Soc. A21(5), 1–9.1 (2003)

Dust collection and containment components designed in tandem with a CNC machine tool are critical to managing and collecting graphite dust produced during milling, and the Tongtai TMV-510G is no exception. Absolute offers Donaldson Torit CFM dust collectors and filtration systems with piping to evacuate and collect fine graphite dust, however, other major brands of such systems can also be considered if there is a preference.

O. Knotek, M. Atzor, H.-G. Prengel, On the reactively sputtered Ti-Al-V carbonitrides. Surf. Coat. Technol. 36, 265–273 (1988)

K. Holmberg, A. Matthews, Coatings Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineering (Elsevier, Amsterdam, 2009). ISBN 978-0-444-52750-9

0086-813-8127573

0086-813-8127573