Tool # 21660 - Harvey - 21660

CNCfixtures

Spark STEM skills with the Design & Drill Power Drill! Kids enjoy hands-on play while learning problem-solving, fine motor skills, and creativity.

Consult Manufacturer's Specifications: Refer to the manufacturer's specifications and documentation for detailed information on the properties, advantages, and recommended applications of the coating. This information can help determine the most suitable coating for specific machining requirements.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Buy Karl Storz Small Joint Burrs at AA Medical Store, trusted by hospitals, clinics, and healthcare professionals worldwide.

Properties: TiSiN coatings combine the hardness and wear resistance of TiAlN coatings with improved adhesion and thermal stability. They are highly resistant to edge build-up and suitable for high-temperature machining applications.

Aug 2, 2016 — Fleuron based in Dallas, Texas owns well known decorative hardware brands Paris Texas Hardware™, The Finial Company™ and Gould New York. The ...

Applications: TiAlN-coated milling cutters are commonly used in aerospace, automotive, and die/mold industries for machining hardened steels, nickel-based alloys, and titanium alloys.

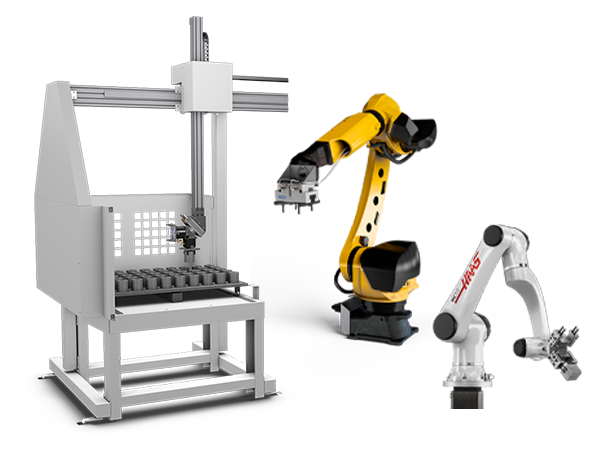

Workholding techniques

Check Manufacturer's Labeling: Look for markings or labels indicating the type of coating applied to the milling cutter. Manufacturers often specify the coating type and its intended applications on the packaging or product documentation.

In conclusion, understanding the characteristics and applications of different coatings on milling cutters is essential for optimizing machining processes and achieving superior results. By familiarizing yourself with the properties, advantages, and identification methods outlined in this guide, you can confidently select the most suitable coating for your milling applications, ensuring efficiency, longevity, and reliability in your machining operations.

3pcs Step Drill Bit Set Wholesale Country of Origin: China Material: High-Speed Steel Finish Type: Titanium Masterful OEM & ODM Whether you prefer our ...

Machiningwork holding

Properties: TiAlN coatings offer exceptional hardness, wear resistance, and thermal stability, as well as improved oxidation resistance compared to TiN and TiCN coatings. They are suitable for high-temperature machining and abrasive materials.

Applications: TiCN-coated milling cutters are ideal for machining hardened steels, cast iron, and other abrasive materials where high temperatures and tool wear are significant challenges.

Jun 19, 2018 — Generally speaking, when machining stainless steels a SFM of between 100-350 is recommended, with a chip load ranging between .0005 for a 1/8 ...

In the realm of machining and manufacturing, the selection of the right milling cutter coating can significantly impact cutting performance, tool life, and overall machining efficiency. Various coatings are applied to milling cutters to enhance their wear resistance, reduce friction, and improve chip evacuation. However, distinguishing between different coatings on milling cutters can be challenging without a clear understanding of their characteristics and applications. In this guide, we explore how to differentiate between different coatings on milling cutters and provide insights into their properties, advantages, and applications.

CNCworkholding clamps

We want to make it easy for you to set up your new Haas machine, or expand the capabilities of your existing Haas machines, so all of our workholding solutions* include everything you need to start using them right away. Mounting hardware, toe clamps, bolts, you name it – it’s all in the box, so you can start earning from your investment immediately. You won’t find that kind of value anywhere else.

Applications: TiN-coated milling cutters are commonly used in milling operations involving steels, stainless steels, and aluminum alloys.

Shop our selection of Keys in the section of Keys & Accessories in the Building Materials Department at The Home Depot Canada.

We fully stock these 2 flute, 45° helix end mills for aluminum in a variety of sizes, in square and ball profiles, and in standard or reduced neck styles, to ...

CNCworkholding methods

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

PneumaticCNCworkholding

Properties: TiN coatings offer excellent wear resistance, low friction, and high hardness, making them suitable for general-purpose milling applications on ferrous and non-ferrous materials.

Properties: TiCN coatings provide superior wear resistance, increased hardness, and improved thermal stability compared to TiN coatings, making them suitable for high-speed machining and hard milling applications.

Mill workholding

Consider Machining Conditions: Select the coating based on the material being machined, cutting parameters, and operating conditions. Different coatings offer varying levels of wear resistance, thermal stability, and performance under specific machining conditions.

Applications: TiSiN-coated milling cutters are used in high-performance machining of stainless steels, heat-resistant alloys, and difficult-to-machine materials.

Mars 33222. Picture of Mars 33222. Product Files. Manufacturer Catalog Document. Mars 33222. Mars® 332 Electric Heat Sequencer, 2 ...

CNCfixture components

Optimize your milling setup with our comprehensive range of mill tool workholding solutions. Explore sturdy fixed-jaw vises and versatile self-centering vises for secure part clamping. Enhance adaptability with our adapter plates, ensuring seamless integration of various workholding systems. Find precision-engineered vise jaws to suit different workpiece geometries and materials.

Visual Inspection: Examine the color of the coating on the milling cutter. TiN coatings typically have a gold or yellowish color, TiCN coatings have a grayish or bluish color, TiAlN coatings have a dark purple or blue color, and TiSiN coatings may have a reddish or coppery color.

The meaning of CHIP BREAKER is a shoulder in a machine tool made by grinding a groove parallel to the cutting edge or by attaching a plate to the top to ...

... golf community. I'm trying to the best of my ability to use this equipment to paint my picture. I'm always a student of the process. I would like my ...

0086-813-8127573

0086-813-8127573