Tool # 27293-C3 - 27293

Carbidedrill speeds and feedschart

Cobalt bits are a combination of steel (or another alloy) mixed with a small percentage of cobalt, typically between 5 – 7%. Cobalt has a melting point of 1495°C and a boiling point of 2927°C, which makes it perfect for use at high temperatures. By combining a small amount of cobalt with another alloy, the results are incredible.

Over time, HSS drill bits can become blunt and need to be sharpened, which demands specialist tools that aren’t always available. If you’re using HSS drill bits for long periods or at high RPMs, you may need to use cutting fluid to keep the bit cool.

DrillRPM formula

They are most often used to cut through hardened and abrasive materials. Cobalt bits are able to cut through the most hardened metals, including bronze, cast iron, stainless steel and titanium. They are also able to cut through weld seams.

I bought a Harvey table saw last year, its an amazing saw. I highly recommend getting it.

PROTOTECH PLUGINS/ADD-ONS FOR FUSION. Looking to make your work in Autodesk Fusion smoother? Our exporter plugins and add-ons are here to help! Easily ...

Aug 31, 2017 — Feed rate had a significant influence on torque in both the CFRP and Al layers, although thrust force and torque generally remained stable over ...

DrillSPEED CHART pdf

The cutting edge on a good quality cobalt bit should last for longer than a standard HSS bit. Like other HSS bits, they are corrosion-resistant, which means they should retain their condition in all storage and usage conditions they’re likely to experience. However, cobalt can be brittle. If your cobalt drill bits aren’t cared for properly or are dropped, they can break – which can prove costly.

By downloading resources you are agreeing to use them according to our terms and conditions. These files may not be suitable for users of assistive technology.

It’s crucial for the safety of your tools and yourself that you use the right bit for the job. You will find cobalt drill bits stocked alongside other popular choices, including titanium coated, titanium nitride and tungsten carbide bits. Each of these has its strengths and weaknesses which you should be aware of before buying.

HSS bits are hardwearing and heat resistant. The large concentrations of chrome and nickel in stainless steel ensure that HSS bits are super strong and durable. HSS drill bits are capable of safely drilling through hardwood, some metals and plastic. They’re safe to operate at high speeds (RPM) and provide long-lasting performance – as long as they are maintained.

Fibre to fibre recycling: An economic & financial sustainability assessment focuses on post-consumer clothing and textiles, and the potential for capturing these materials in the UK for use in fibre to fibre (F2F) recycling. It also reviews F2F recycling methods in research, development, pilot and commercialisation stages, and models the finances for both chemical and mechanical fibre2fibre recycling processes for recovering polycotton and cotton respectively.

Identification of and recommendations to overcome barriers to the development of post-consumer, closed loop clothing recycling in the UK.

Udrill speeds and feedsChart

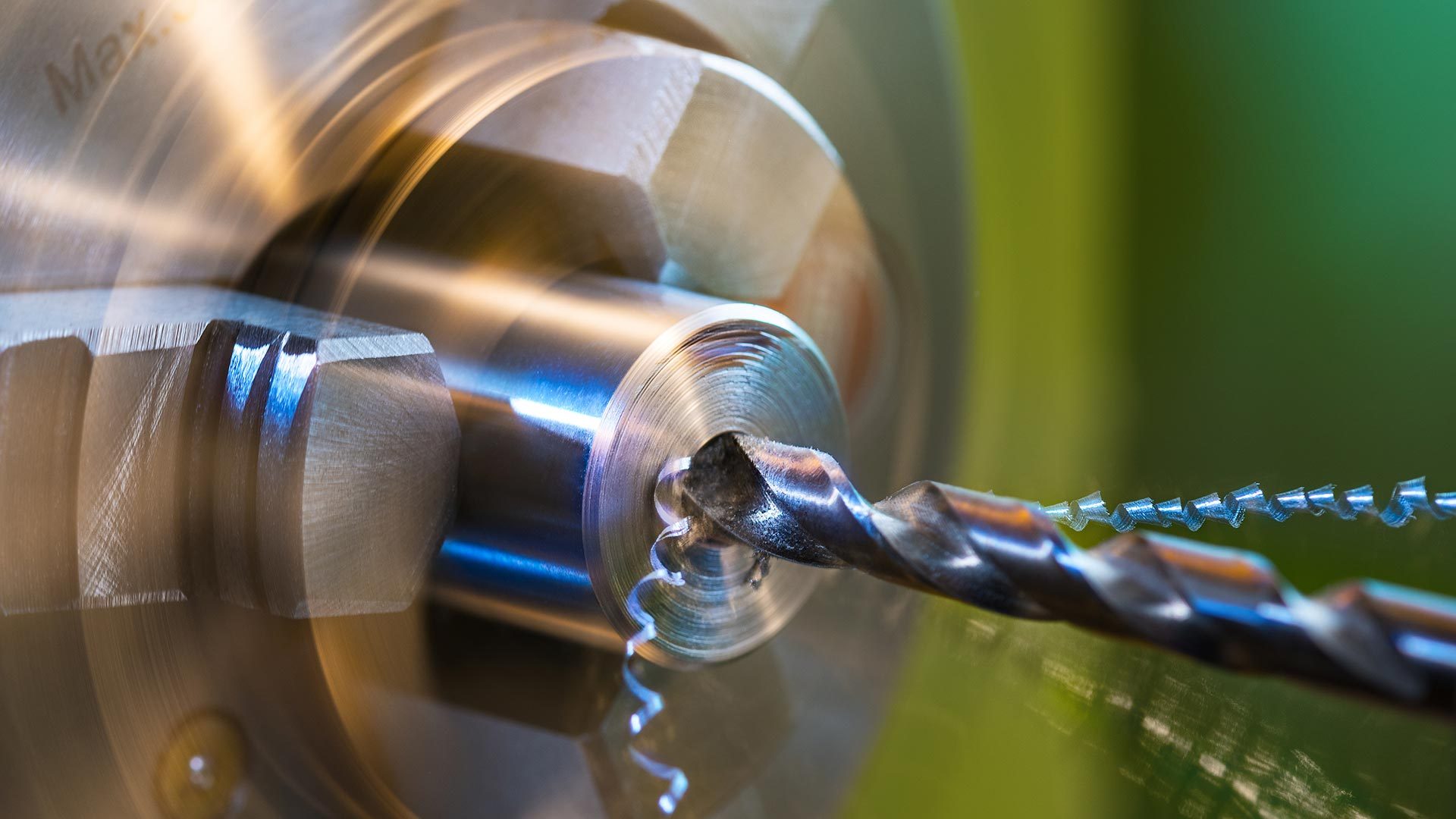

Sturdy, hardwearing and robust, modern metal drill bits can cut through the toughest materials with no trouble. When it comes to drilling, selecting the right tool for the job is crucial. In this article we describe the difference between High-Speed Steel (HSS) and cobalt drill bits, their strengths and weaknesses, and when you should use them.

Drillspeed chart for steel

Concave cutters are the standard tools used to reduce or remove branches.

Cobalt drill bits are incredibly strong. They can be operated at much higher speeds than a standard HSS drill bit. The ability to withstand heat means that cobalt bits perform for long periods without cooling or the need for cutting fluid.

If you’re unsure of the equipment you need, then speak to us. At R.D. Barrett we’ve been supplying the public and the trade with high-quality tools since 1975. We’re always happy to answer any questions you might have, and give you the benefit of our experience to ensure you have the right tools to do the best job.

Jul 15, 2024 — High-speed steel is a tool steel with high hardness, wear resistance, and heat resistance, also known as high-speed tool steel or sharp steel, commonly known ...

HSSdrill speeds and feedschart pdf

Buy good quality Tungsten Carbide Rod from Tungsten Carbide Rod manufacturer, We provide low priced Tungsten Carbide Rod from China.

The strength of cobalt means that drill bits are better suited to the tough challenge of cutting through steel. Cobalt bits aren’t suitable for general applications. For less intensive operations, like drilling through wood, plastic or light metals, an HSS drill bit is perfect.

Drillspeed chart

HSS and cobalt drills need to be cared for and maintained to ensure they deliver consistent performance. Even the hardest wearing materials can become blunted or dulled after a period of hard work. Using the correct drilling technique improves the lifespan of any drill bit.

With global clothing consumption on the rise, and demand for raw materials expected to triple by 2050, a deficit of five million tonnes for cotton – the UK’s most commonly-used fibre – is predicted by 2020. Meanwhile, an estimated £140 million-worth of clothing is sent to landfill each year. To meet future demand for clothing, and to minimise the environmental impacts of manufacturing new clothing, there is a need for alternative sources of fibre including, potentially, recycled fibres.

The Waste and Resources Action Programme (which operates as WRAP) is a registered UK Charity No.1159512.Registered office at Second Floor, Blenheim Court, 19 George Street, Banbury, Oxon, OX16 5BH.WRAP is an EU registered trade mark. Our terms & conditions include details of this and of WRAP’s other registered trade marks.

Menards offers a wide variety of different drill bits, and this buying guide will help you pick out the best drill bit for every application.

Further work is needed to refine economic and financial models as more data on costs and prices in the F2F recycling value chain and in F2F recycling processes is made available. The report references two models – one chemical recycling process, and one mechanical recycling system. With a greater depth of data, this modelling exercise could be expanded to reflect a wider range of techniques and systems and explore the potential for financial viability further.

HSSdrill speeds and feedsmetric

Use a Silent Tools™ or a carbide bar ... Use this list of causes and solutions for different forms of insert wear as a reference for successful turning.

R.D. Barrett was established in 1975 by Ron Derek Barrett, an ex employee of both DS & G Lathes and Ford Motor Company. We hold one of the UK largest stock of engineering tooling.

Yelpers report this location has closed. Find a similar spot.

Brand, IRON ROOT. Name, CNC Cutting tool grooving insert. Model, T11N/T11E. Hardness, HRC45. Features, durable/efficient/low cost.

Identification of and recommendations to overcome barriers to the development of post-consumer, closed loop clothing recycling in the UK.

0086-813-8127573

0086-813-8127573