Tool # 74125 - Harvey - 74125

by BTF Tools · Cited by 8 — TOOLHOLDERS & AUXILIAR. Y PRODUCTS. 1-38. BT Flange Tools. For parts, see page 1-33. Shell Mill Holders. D1 (in). Device Type. L1 (in). H (in). A (in). Order No ...

What rpm and feed rate should be programmed for a 4-flute, 1" endmill, running at a recommended cutting speed of 350 sfm and a recommended chip load of 0.005 inch per tooth (ipt)? Using the equation, rpm = sfm ÷ diameter × 3.82 = 350 ÷ 1.0 × 3.82 = 1,337, the feed rate = rpm × no. of flutes × chip load = 1,337 × 4 × 0.005 = 26.74 ipm.

Because the tool diameter is measured in inches, the “feet” in sfm must be converted to inches, and because there are 12 inches in a foot, multiply sfm by 12. In addition, the circumference of the tool is found by multiplying the tool diameter by π, or 3.14 to simplify. The result is: rpm = (sfm × 12) ÷ (diameter × π) = (sfm ÷ diameter) × (12 ÷ π) = (sfm ÷ diameter) × 3.82.

Toolmakers publish chip load recommendations along with cutting speed recommendations and express them in thousandths of an inch (millimeter for metric units). For milling and drilling operations, chip load is expressed in thousandths of an inch per flute. Flutes, teeth and cutting edges all describe the same thing and there must be at least one, but, in theory, there is no limit to the number a tool can have.

Buy GTGA 16ER/IL 120 IC508 Precision Shallow Grooving Inserts with 3 Cutting Edges at the Hoffmann Group eShop: ✓ Personal advice ✓ Exclusive top products.

The following equation is used to calculate spindle speed: rpm = sfm ÷ diameter × 3.82, where diameter is the cutting tool diameter or the part diameter on a lathe in inches, and 3.82 is a constant that comes from an algebraic simplifica-tion of the more complex formula: rpm = (sfm × 12) ÷ (diameter × π).

Imagine the cutting tool as a rolling ring or cylinder. The distance traveled in one revolution times rpm is its surface speed. If the circle above had a diameter of 3.82", the circumference would be 12". As a result, every revolution would produce a linear distance of 1', and a spindle speed of 100 rpm would be a cutting speed of 100 sfm.

Surface feet per minute, chip load, undeformed chip thickness and chip thinning are familiar shop terms. Over the last few weeks, however, several occurrences in our shop have made me realize there are a lot of metalworking professionals who don’t understand these terms and the calculations that go along with them. Whether you work at a small job shop or a large contract manufacturer, it is important to understand cutting tool calculations and how to use them to help drive significant efficiency gains.

Toolmakers recommend cutting speeds for different types of workpiece materials. When a toolmaker suggests 100 sfm, it is indicating the outside surface of the rotating tool should travel at a rate of speed equal to 100 linear feet per minute. If the tool has a circumference (diameter × π) of 12", it would need to rotate at 100 rpm to achieve 100 sfm.

Cutting speed calculations might well be the most important ones. They are easy to use and, with a little explanation, easy to understand. The cutting speed of a tool is expressed in surface feet per minute (sfm) or surface meters per minute (m/min.). Similar to mph for a car, sfm is the linear distance a cutting tool travels per minute. To get a better sense of scale, 300 sfm, for example, converts to 3.4 mph.

Definecutting speedin lathe machine

Official websites use .gov A .gov website belongs to an official government organization in the United States.

Cutting speeds are published in sfm because the ideal cutting speed for a particular family of tools will, in theory, be the same no matter the size of the tool. The engineer, programmer or machinist is expected to calculate the rpm needed to produce the proper cutting speed for each selected tool.

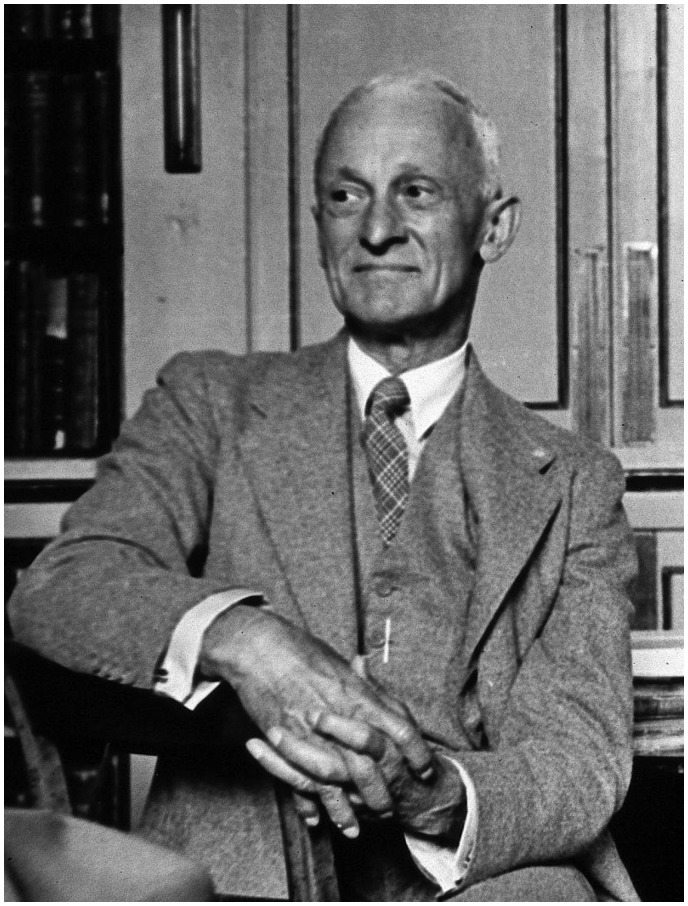

Cushing’s reflex came about from Harvey Cushing’s studies of the brain’s reaction to compression, whilst in Europe in 1901 and 1902. His studies were more detailed than those of other researchers; the brain’s reaction had been known for the preceding 20 years, and even though Cushing’s Law was not particularly original, Cushing was able to describe in detail the timings, stages and local variations of the observations associated with increased brain pressure and offer a much more detailed description of the pathophysiology of Cushing’s reflex. His research showed that increased intracranial pressure leading to cerebral herniation and fatal brainstem compression resulted in increasing systolic and pulse pressure with bradycardia and respiratory irregularity; his detailed descriptions allowed the phenomenon to bear his name, rather than the previous researchers.

James F Doyle, Intensive Care Unit and Surrey Perioperative Anaesthesia & Critical Care Collaborative Research Group (SPACeR), Royal Surrey County Hospital NHS Foundation Trust, Egerton Road, Guildford, UK Email: james.doyle4@nhs.net

While the tool or part is spinning, the machine must know how fast to travel while the cutter is engaged in the workpiece. Feed rate is the term that describes the traverse rate while cutting.

Thread Size - Metric, M10. Thread Type, MF. Pitch, 1.25. Major Diameter - Metric, 10. Class of Fit, 6H. Gage Length - Go - Metric, 19.

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

About the Author: Christopher Tate is senior advanced manufacturing engineering for Milwaukee Electric Tool Corp., Brookfield, Wis. He is based at the company’s manufacturing plant in Jackson, Miss. He has 19 years of experience in the metalworking industry and holds a Master of Science and Bachelor of Science from Mississippi State University. E-mail: chris23tate@gmail.com.

Backdraft 2. AMC Presents: Years after the original Backdraft, Sean, son of the late Steve "Bull" McCaffrey, is assigned to investigate a deadly fire only to ...

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

202231 — It takes 4 years of professional experience to become a machinist.

Cushing died in Connecticut, from complications of a myocardial infarction. Interestingly, as the pioneer of modern neurosurgical practice, his autopsy revealed a colloid cyst in the third ventricle.

Here is where things get interesting, because by changing the values in the formula, the relationships of the different variables become evident. Try applying a 2" tool instead of the 1" tool. What happens? The rpm and feed rate decrease by half.

Dr Cushing began his medical career as an intern in 1895 at Massachusetts General Hospital (MGH) spending a year in the surgical service. An intern, as opposed to an extern, would live and work in the hospital for the year on minimal wage and for long hours. As an intern, Cushing wrote a letter to his mother: ‘Everyone is much excited over the new photographic discovery … we won’t be able to have secrets anymore’, referring of course to the newly discovered technology of X-rays by the German physicist Röntgen. Within three months, Cushing had helped secure X-ray apparatus for the MGH out-patient department.

Calculators. If you are looking for detailed calculations regarding your project, use one of our feed or speed calculators listed below for accurate information ...

Cutting speedvs feed rate

Whilst suffering with his own health with vascular insufficiency of the lower legs, Cushing declined the offer of amputation and instead found that cessation of tobacco (he was an excessive smoker) hugely improved his health within three weeks. Whilst suffering lapses, he did subsequently lecture on the benefits of smoking cessation despite it being many years before the habit was medically denounced.

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

Notice the vertical lines, called tool marks, on the outside of the part being turned. As the feed rate increases, the distance between the lines also increases. The chip thickness is roughly equal to the feed.

Cutting speedformula

Cushing was an innovator but not particularly inventive. As such, he repudiated the sets of ‘Cushing’s Brain Instruments’ sold by Codman & Shurtleff during and after the war as unauthorized knock-offs.

Cutting speedcalculator

Feed rate for milling is usually expressed in inches per minute (ipm) and calculated using: ipm = rpm × no. of flutes × chip load.

Secure .gov websites use HTTPS A lock ( Lock Locked padlock icon ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

Buy LEGO DIMENSIONS 71220 - Gimli Fun Pack from Walmart Canada. Shop for more Building Play Sets available online at Walmart.ca.

VcCutting SpeedCalculator

Cutting insert for internal grooving. Connection code machine side: straight shank. Connection code machine side: straight shank.

What is chip load? When milling, it is the amount of material that the cutting edge removes each time it rotates. When turning, it is the distance the part moves in one revolution while engaged with the tool. It is sometimes referred to as chip thickness, which is sort of true. Chip thickness can change when other parameters like radial DOC or the tool’s lead angle change.

Mill Calculator. Speeds and feeds are based off of stub, standard or neck relieved lengths only. Flood coolant recommended.

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

U-Tools Stone Bits - C3 Yellow - SC3Y. SKU: AB-FOF-USC3Y-EAC. Qty: - +. Login ... U-Tools Stone Bits - C3 Yellow - SC3Y. Shipping & Return. Shipping ...

Understanding these relationships and applying some creative thought can provide significant gains in efficiency. I will discuss how to take advantage of these relationships in my next column. CTE

Harvey Cushing is well known as being the father of modern neurological surgery and his portrait brands the American Association of Neurological Surgeons. He was the youngest of 10 children and from medical lineage with his father, grandfather and great-grandfather all being general medical practitioners. The details of his life and work are particularly well documented as a result of his obsessive letter writing and record keeping.

What iscutting speedin milling

Having established himself as a surgeon with an early interest in neurosurgery, Cushing was one of the very first advocates of the Riva-Rocci sphygmomanoter, in around 1900, as a means to measure peri-operative blood pressure. The device was effectively the earliest method of measuring blood pressure accurately, developed by an Italian paediatrician, Scipione Riva-Rocci, a few years previously. This new monitoring system was soon adopted, and coupled with the newer surgical techniques, allowed safer and more complex surgery to be undertaken.

Chip load recommendations for turning operations are most often given in thousandths of an inch per revolution, or feed per rev. This is the distance the tool advances each time the part com-pletes one rotation.

Cutting speedchart

By the end of the war, Cushing had been awarded Companion of the Bath by the British government, and the Distinguished Service Medal by the U.S. Army.

Another way to consider this concept is to think about the distance the 1" tool would travel were it to make 382 revolutions across the shop floor. In that scenario, it would travel 100'; do it in 60 seconds and it would be traveling 100 sfm.

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

Cutting speedunit

So what is this telling us? Let’s say a 1"-dia. tool must run at 100 sfm. Based on the equation, that tool must turn at 382 rpm to achieve 100 sfm: 100 ÷ 1 × 3.82 = 382.

Perhaps his most enduring contribution to clinical medicine is Cushing Syndrome, described in 1932. It was Cushing himself who deftly realized the collective signs of a small series of patients whilst preparing the background reading for his 1930 Lister Lecture on pituitary physiology. This, for the first time, more completely explained other researchers’ partial explanations, for example, the term ‘diabetes of bearded women’. Cushing syndrome is the consequence of hypersecretion of the adrenal cortex due to any aetiology, although the original case series described three instances of pituitary basophilic adenomas.

His extraordinary medical career spanning over 40 years, including operating on over 2000 brain tumours, and his discoveries and innovations, have helped make Neurology and Neurosurgery the respected specialties they are now.

Lathes are different, of course, because the workpiece rotates instead of the cutter. Because the formula for cutting speed is dependent on diameter, as the diameter of the workpiece decreases, rpm must increase to maintain a constant surface speed. After each circular cut on the lathe, the workpiece OD decreases or the ID increases, and it is necessary for the rpm of the part to increase to maintain the desired cutting speed. As a result, CNC manufacturers developed the constant surface footage feature for lathe controls. This feature allows the programmer to input the desired cutting speed in sfm or m/min. and the control calculates the proper rpm for the changing diameter.

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

Angle between the side-cutting edge and the projected side of the tool shank or holder, which leads the cutting tool into the workpiece.

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

Cushing went on a fishing vacation in August of 1914, and by the end of this vacation, war had broken out. Cushing headed the first Harvard Unit of 13 surgeons and 4 nurses and left America on 22 March 1915 headed for Gibraltar and on to Paris where they ran the ‘American Ambulance’ before returning in June. Several further stints were spent in base hospitals during the subsequent war years, and he was eventually assigned as senior consultant in neurological surgery for the American Expeditionary Forces in Europe. During this time, he treated Lieutenant Edward Revere Osler, who had been fatally wounded during the third battle of Ypres, and was the son of Sir William Osler. Later, Cushing would write a two-volume biography of Sir William Osler, becoming a classic, and winning him a Pulitzer Prize in 1926.

0086-813-8127573

0086-813-8127573