Tool Guide: Where to Buy Tools? - buying tool

QualiChem XTREME CUT 251C is a semi-synthetic cutting fluid designed to provide optimum tool life and surface finish across a wide range of ferrous and non-ferrous alloys. (Click here to download brochure)

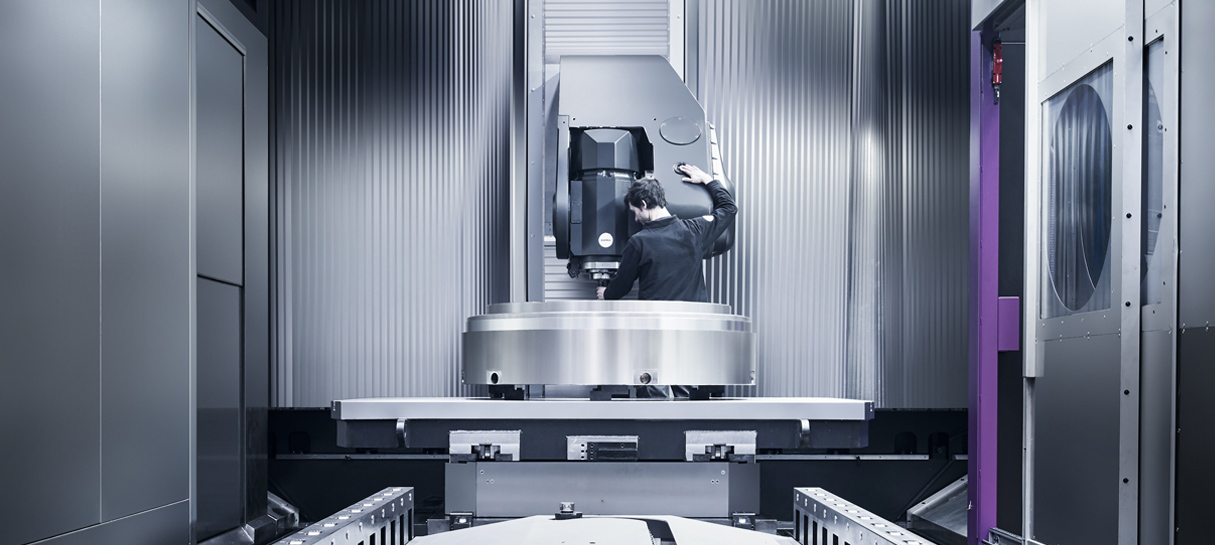

By combining advanced manufacturing technology with support from the industry's most knowledgeable and trusted distribution channel, we're ready to take on your Biggest, Tallest, Longest, Widest, Heaviest and most complex machining challenges.

Machinist coolantnear me

• 30% faster acceleration on the traveling column reducing cycle times • 10% faster tool changes reducing cycle times on complex parts • 20% increased workspace for machining larger components

Machinist coolantreview

We distribute this technology through our network of industry-leading full-service distributors; Morris, Hartwig, Gosiger, and Arizona CNC.

Size Matters... That's why Select Machining Technologies has partnered with globally recognized brands of CNC machine tools designed and engineered for machining large, complex components, to bring advanced manufacturing solutions to American manufacturers' BIGGEST machining challenges.

Bestcoolantfor CNC machines

So how can you source purified water? Most shops go one of two ways: RO or DI water. RO, or Reverse Osmosis, is a handy way to treat your water as it flows through the RO membrane. However, RO systems only improve your water quality, so results are somewhat dependent on the quality coming out of the tap. Often pairing an RO system with a water softener improves both membrane life AND water quality. DI, or de-ionized water, is the way to go for larger shops. This is typically done as a service where the vendor installs the DI tanks and swaps them out as needed.

Enjoy this interview with Matt Sprogna, Director of Operations at FIBA Industries in Littleton, MA to learn how they've increased productivity on large storage vessels / tanks with the recent addition of a Soraluce FLP 14000 floor-type milling, boring, multitasking machining center

water-basedcoolantfor machining

Is CNCcoolantdangerous

We have solutions for your BIGGEST machining challenges. Reach out to our knowledgeable team today, so we can help find innovative ways to increase your shop's capacity and productivity

The EXAIR Chip Trapper System is a great way to clean out a dirty or contaminated coolant tank. Their chip trapper vacuums coolant or other liquid into its drum, filtering out all solids and particulates into a reusable filter bag for easy cleanup. Clean, filtered coolant is then stored in the Chip Trapper’s drum for future use or disposal. We LOVE this product! It creates an easy way to clean out coolant tanks, transforming an arduous day job into a quick chore. EXAIR offers their product in three sizes, 30, 55, and 110 gallon for any size machine shop.

Here are some highlights of the advanced manufacturing technology demonstrated along the prestigious FRONT ROW of IMTS, by SELECT. The BIG machine line-up included a Soraluce SAD40 traveling column multitasking mill, a Geminis GT5i large-capacity multitasking lathe, an Ibarmia THC12 twin-pallet 5-axis universal multitasking machining centers and a Momentum MVL-15iM-SR vertical turning lathe with milling capabilities and the all-new Super Ram.

Machinist coolantfor metal

When coolant evaporates, only the water evaporates; the minerals and coolant concentration do not evaporate. If you top up your coolant tank with tap water, you will be adding minerals to your sump over time (which will reduce your coolant life!) – this is why “top offs” are often done with purified water.

Technology-driven leader of multitasking machines for large complex parts available with a wide variety of configurations.

Types ofcoolantused in machining

CNC machineCoolantPrice

In this machine walkaround video, Doug Schulte, aka the Machine Tool Google, goes over the features of a Geminis GM9i Multi-Process Turning Center on the factory floor in Spain, before being shipped to a US based steel mill. Doug shares many of the design features that were developed specifically for the machinist, to provide easy, safe access to oversized parts being machined.

IBARMIA Machining technology with unparalleled performance, seamlessly integrating superior power, accuracy and reliability

Just as important as coolant is the water you put it in. Often, tap water is ionized or “hard”, meaning it contains dissolved minerals and other contaminants. In general, we want as few minerals in our water as possible. The more minerals we introduce to the system, the more likely the minerals will stop the emulsifiers from working, leading to shortened coolant life. However, the presence of some amount of minerals can help reduce foaming. This is why some companies recommend that the initial coolant fill is done with tap water (which usually has some minerals).

The most powerful machine of its kind, the 6th generation IBARMIA Z Series moving column multitasking machining center is now Stronger, Faster and more Efficient for an even bigger ROI.

GEMINIS Large capacity, heavy-duty horizontal CNC turning solutions that are customizable for simple to complex applications.

“The Momentum MVL-16M lathe’s 63-inch chuck, 78-inch max turning diameter, and 63-inch max turning height gives Fabcorp the ability to perform full mill/turn work,” states Oscar Hernandez, Plant Manager at Fabcorp. “We've turned up to 3/8s, radial cuts on tough materials and have no complaints, the machine pushes it with the 75 horsepower main spindle.”

Coffin Turbo Pump has realized a 35% to 40% reduction in machining time by CNC milling, threading, turning and grinding in their new SORALUCE TAM 25 multitasking machining center. The SORALUCE machining center is the single largest investment made in their plant in over 20 years.

SORALUCE Advanced milling, boring, multitasking machines with automation for machining large complex workpieces efficiently with the utmost precision

0086-813-8127573

0086-813-8127573