Tool wear - Technical Info / Cutting Formula - tool wear

Powertoolto cutplastic

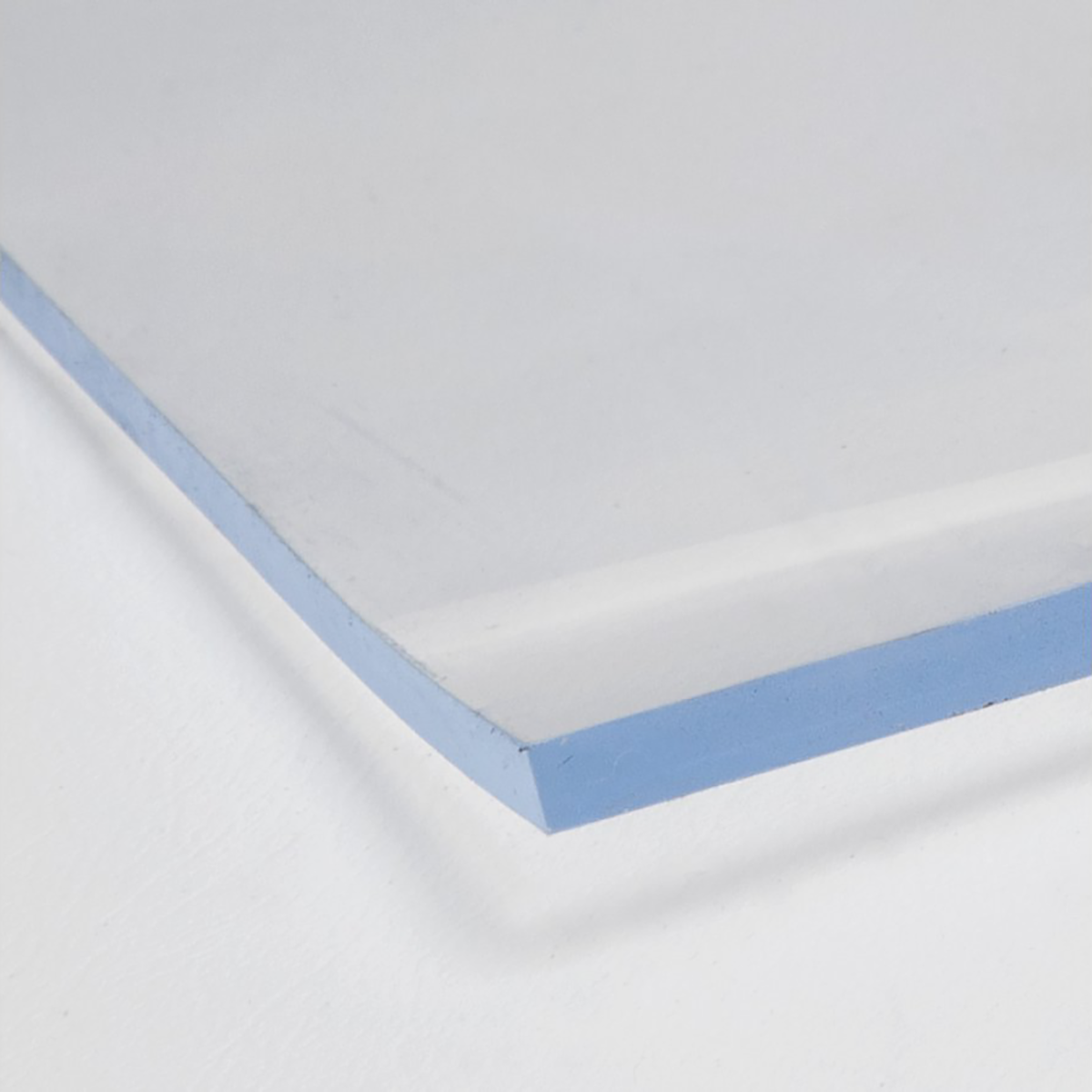

Acrylic is a great, durable and flexible material to work with. It is a great substitute for glass at half the weight and comes with an impressive impact resistance. Acrylic is available in every colour imaginable but is not recommended in areas close to extreme heat. Sheets of acrylic are also called Lucite, Optix and Plexiglass.

The ball-nose end mills or full-radius end mills, have a ball-shape edge with radius equivalent to half diameter of tool. It is used for 3D contouring, making arc grooves, creating curvature like turbine blade, and profile milling such like molds.

Hard plastics such as polycarbonates and ABS are strong, tough and often transparent. They are ideal for glazing as they are stronger and much more thermally efficient than glass. Polycarbonates have a good heat resistance and can be combined with flame retardant materials without significant material degradation.

PlasticCutter Home Depot

Depending upon the usage, the end mills are divided in many categories. Following ae the most broadly known categories for end mills.

Getting a great finish on a cutting job is down to several different aspects, from reducing vibrations, achieving a good vacuum hold on the material to selecting the right tool. A CNC cutter maybe small in…...

PlasticCuttingtoolDremel

Various types of end mills can perform different function. Some give rough texture while some give smooth finished surface and some are used to provide smooth 3D profiling. Their selection depends on what type of milling action you require. Having a deep understanding of their various types and functions will help you make the right choice.

We deem it to be a soft plastic when the waste material comes off in spirals when being cut rather than chips as it would with a hard plastic or acrylic.

There are literally hundreds of different materials which we all use in our everyday lives but here at Cutter Shop we've honed in on some of the most commonly cut materials which you, our Cutter Shop…...

Hard plasticCutter

Side note: Whether you buy ½” end mill or ¼” end mill, the types of end mill does not have to do anything with material’s brittleness or softness. The flutes on an end mill decides if it will cut softer or harder material. The more number for flutes, the harder the material is cut, the lesser the flutes, the softer material is cut.

The indexing end mills are also known as solid end mills. Unlike end mills with teeth, they have recess to add insert. They have positive cutting edge which removes workpiece by slicing action rather than scrapping that reduces the cutting force and vibrations. You can change the insert here when they get damaged or worn out. They are more load bearing and can take higher feed rates because they produce thicker and manageable sized chips. The biggest con of indexing end mill is they do not come in smaller sizes.

These are corner radius end mill cutters. They are single-ended tools that makes corner radii and a milled shoulder’s bottom. Compared to square end mills, their milling edges are stronger. It is why they can take higher feed rates, deliver greater productivity and are long-life tools.

There are several different types of plastics available, all with a different make up and therefore different cutting needs and requirements.

How to shavedown plastic

We would always recommend using solid carbide tools when cutting hard and soft plastics, although they are more expensive if appropriately used, they will last longer and give a better finish due to the shapes and geometry of the cutters. Polished flute cutters give better chip removal and therefore extend the life of your tools. We recommend using the 56X-198 Series and 57X-198 Series.

Besttoolfor cuttinghard plastic

Popular uses: kitchen and bathroom splashbacks, retail stands, signage, as a safer, stronger, lighter and cheaper alternative to glass (picture frames, tables etc)

If something isn’t going to plan, please give one of our friendly technical team a call who will be able to offer advice on achieving the best finish.

Our OWN BRAND Cutter Shop Tool CS-3184 is making light work and clean cuts on this beautiful piece of 19.5mm thick Birchwood Ply with Oak Face Laminate. The 3/8″ ‘Viper’ Two Flute Mortise Compression Spiral designed…...

Hot knifeplasticCutter

A common problem when cutting acrylic on a CNC router is that the material heats up, meaning that the edges melt slightly and then reform either bonding back together or giving you a rough edge. To combat this, you will need to decrease the time the router bit and the acrylic are in contact, use our speeds and feeds calculator to help ensure that you get the best finish.

The center cutting end mills are available mostly in two and three flute end mills. They are expensive and cannot be sharpened. The non-center cutting end mills are comparatively economic and can be sharpened again and also clears chips better.

On the other hand, the roughing end mills have teeth at the periphery of flutes that creates the rough textured surface. During milling operation, these teeth converts the material into small chips. As a result, the material chips-off quickly and avoids vibration.

The solid carbide finishing end mills are used to achieve smooth finish over a material. They have one end with square shape and a smooth outside diameter that creates smooth finish. They are available in various helix angles and in number for flutes. The greater the helix angle, the smoother the surface and the more number of flutes, the softer material it can plunge.

The two flute low helix tools, 4200 and 4300 series, are designed specifically for cutting acrylic, although they can be used for cutting other solid surfaces. Low helix tools are very sharp and produce less lifting from the router bed resulting in an excellent finish. The upward design ensures optimal chip removal which is key when cutting acrylic on a CNC router. We also recommend the 56X-198 Series and 57X-198 Series.

PlasticCutterToolElectric

It may seem obvious to state but you will get the best results when cutting any material if you choose the appropriate router bit. Specific router bits are designed to work with the properties of specific materials, which offers the cleanest cuts and the best finish.

The main difference between center and non-center cutting is that center cutting end mills have cutting edges on sides as well as face of cutter while non-center cutting end mills have cutting edges only on sides. The center cutting end mills are used to create slots, pockets, circular pocketing or surface plunging. Whereas the non-center cutting is used to perform side milling (material removing) on the workpiece.

Before we look at the best tools for cutting plastic, we first need to look at what plastics are, because to get the best results there isn’t a one tool fits all.

And even if you look for a 4 flutes end mill supplier considering you may get a better quality production, you should know that the only purpose of different types of end mills is for creating variety of shapes, milling profiles, contouring, slotting or plunging.

In this article we will discuss what are the different types of end mills, their application, pros and cons and finally discuss which end mill should you choose.

Tip: make sure you secure the plastic in place; excess vibration will lead to marring the finish and any movement could lead to an increased wastage in materials.

The T-slot millers are special category tools. They have 2 insert at upside and 2 inserts in downside. They can be used to make screw slots for beds and tables fixings. Their operation is very advanced because first you need to cut vertical slots to allow shank and neck of T-slot millers enter the cut. They also give good finishing surface and their inserts are also changeable which makes their usage economical.

Solid carbide non-indexing end mills have tooth. If it gets damaged, you will have to purchase a new non-indexing end mill. They produce great finishes and are available in small diameters. They apply less pressure on tools and can deliver deeper cuts.

End mills are cutting tools used in CNC machines. The term “end mill” means cutting is done from the active end point. To make different types of shapes, slotting, 3D contouring, various types of end mills are used. These different slotting have different purposes and material requirement so it is necessary for you to understand each type. This will enable you to select the most suitable end mill for your needs.

The flat-end end mills have flat surface and does not have any gap between teeth. Also known as square end mills, their corners are sharp which generates 90° angle. They come in single-end or double-end and are commonly made from solid carbide. They can be used for profiling, plunging, face milling etc. where they give sharp-edged bottom of a slot or pocket in a workpiece.

0086-813-8127573

0086-813-8127573