Tool, Machine, and Equipment: Safety and Operation - toolmachine

During the planning stage of a machining project, the construction material is a key consideration. For products that require a high strength-to-weight ratio, corrosion resistance, electrical conductivity, anodization, and recyclability, aluminum is a perfect option. If you need assistance on your next aluminum machining project, the experts at Ardel Engineering are here to help.

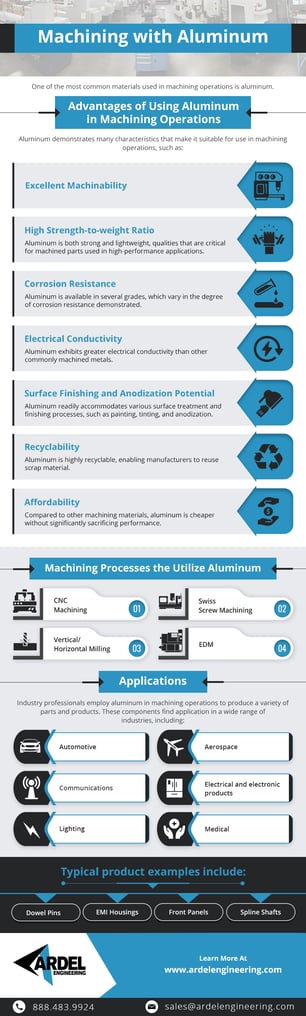

Typical product examples include dowel pins, EMI housings, front panels, lighting fixtures, medical devices, and spline shafts.

Due to its lighter material weight, lower material hardness, and greater formability, aluminum is ideal for use in machining and other manufacturing operations. Below we highlight some of the other advantages of using aluminum for machining applications, discuss how aluminum is used in various machining processes, and outline some of the typical machined parts made from aluminum.

“Machining” is an umbrella term that encompasses a range of subtractive manufacturing processes—e.g., milling, turning, drilling. There are also several types of machining technologies and techniques—e.g., CNC machining, Swiss screw machining, vertical and horizontal milling, and electrical discharge machining (EDM). Below we outline how aluminum is handled in each of these machining methods.

Industry professionals employ aluminum in machining operations to produce a variety of parts and products. These components find application in a wide range of industries, including:

Yes, opt-in. By checking this box, you agree to receive our newsletters, announcements, surveys and marketing offers in accordance with our privacy policy

In addition to its excellent machinability, aluminum demonstrates many characteristics that make it suitable for use in machining operations, such as:

In the world of precision machining, choosing the right method can make a significant difference in the quality, efficiency, and cost-effectiveness of manufacturing processes. One method that stands out for its precision and versatility is Swiss machining. With Ardel Engineering, explore what Swiss machining is, when to choose it, its advantages, and applications.

Machining is a subtractive manufacturing process, meaning it removes material from a workpiece to create the desired part or product. It is highly versatile, accommodating a wide range of metal and non-metal substrates. One of the most common materials used in machining operations is aluminum.

As indicated above, the machining process accommodates a variety of materials, ranging from metal and plastic to paper and wood. In addition to aluminum, some of the materials regularly employed in machining operations include other metals (e.g., steel and stainless steel) and thermoplastics (e.g., ABS, PEEK, POM, and PTFE). Compared to these materials, aluminum offers a number of advantages:

The 74025 Grating Assembly is designed for installation into the Oriel® Cornerstone 130 family of monochromators. This 30 x 30 mm grating comes bonded to a mount, allowing it to be installed inside the instrument. The grating efficiency exceeds 20% over its entire operating range, with a peak efficiency exceeding 75% at its blaze wavelength. This Grating Assembly may be installed in the field, after which the grating must be aligned and calibrated. However, it is suggested to return the instrument to Newport for grating installation and calibration. During recalibration, the instrument is thoroughly assessed to ensure optimal performance and routine maintenance services are performed. The monochromator is returned with a Certificate of Calibration, guaranteeing the instrument meets or exceeds it specifications.

At Ardel Engineering & Manufacturing, we specialize in the precision CNC machining of parts and products made from a variety of metals, plastics, and engineering-grade materials. To learn more about our aluminum machining capabilities, contact us or request a quote today.

Many steps go into manufacturing a complex part, which is why it is crucial to maintain a cooperative effort across all departments in order to achieve high quality, cost effective parts. Explore how to achieve this goal in our in-depth eBook that offers design tips for machining parts.

Choose products to compare anywhere you see 'Add to Compare' or 'Compare' options displayed. Compare All Close

Ardel Engineering stands at the forefront of precision manufacturing, offering state-of-the-art machining services through vertical and horizontal CNC milling machines. Our commitment to excellence is reflected in our adept utilization of advanced machinery and techniques to meet the stringent demands of various industries.

0086-813-8127573

0086-813-8127573