Travers Tool Catalogs - free tool catalogs by mail

Machining Case Hardened steel parts, through Hardened steel parts and induction surface Hardened steel parts offer different challenges in terms of chip control. Tungaloy offers ground chip groove geometries such as HF, HM or laser etched geometry like HP which make chip control easier and also help in holding closer tolerance of the machined surface. All chipbreakers are available in appropriate coating per application.

Using a hammer drill increases the likelihood of concrete cracking. To minimize the risk of concrete damage, it’s advisable to drill without the hammer function, even though it may take longer. The Adiseal Ultimate masonry drill bit is the swiftest option for non-hammer drilling and has been tested to achieve drilling speeds equivalent to an SDS drill bit.

Aerospace, gas turbine and super critical steam turbine applications require use of material which are resistant to high temperatures. Similarly, process pumps working with chemicals and other corrosive are corrosion resistant or show chemical inertness. Inconel 718 is one such important material commonly used in these applications. Engine casing, rings and blades are manufactured using Inconel. Similarly, some of the Oil & Gas applications use valves manufactured from Inconel.

Turninghardened steel

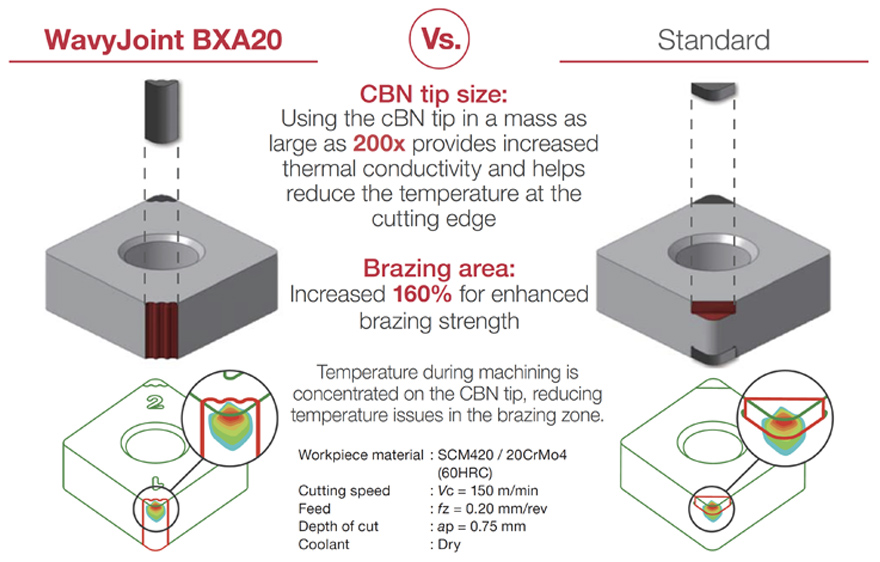

Recently Tungaloy developed a new brazing technology called WavyJoint which significantly increases the surface contact area of brazing thus allowing higher speeds, DOCs, and feeds to be applied.

Today’s technological advancements in various industries such as Automotive, Aerospace, Oil and Gas and Medical demand solutions for machining materials which are more heat and abrasion resistant. Such materials prolong the durability of the component but pose high level of challenges during machining. As a rule of thumb, the cutting tool needs to be at least 3 times the hardness of the material to be cut. So, for machining Hardened steel of about 700Hv, the cutting tool hardness needs to be at least 2100Hv. A general carbide cutting tool / insert has a hardness of 1500Hv making it limited to machine such hard material.

A regular drill, while capable of drilling into concrete without the hammer function, is typically slower than using a hammer drill. The Adiseal Ultimate masonry drill bit significantly accelerates the drilling process and has demonstrated equivalent speed to an SDS drill bit in tests for drilling into concrete brick without the hammer function.

During our test using the Adiseal Ultimate masonry drill bit & multi-material drill bit in a standard cordless drill without the hammer function, it achieved the same drilling speed as a corded SDS hammer drill. Both drills took 5 seconds to drill into the brick. However, the SDS hammer drill caused the brick to break, a common issue with hammer drills. In contrast, the Adiseal Ultimate masonry & multi-material drill bit, used without the hammer function, did not cause the brick to break.

To buy concrete drill bits in the UK, please contact us for details of you local stockist. For other countries that do not have a Adiseal distributor, please visit www.guglue.com

Align the drill bit tip precisely with the marked spot on your material. Apply consistent and even pressure as you begin drilling, ensuring the drill remains level and perpendicular to the material’s surface.

Adiseal Ultimate concrete drill bit is a masonry drill bit that outperforms other drill bits in terms of drilling speed and durability when drilling without a hammer function. It drills a variety of construction materials including concrete, brick, masonry, wood and other materials. Drilling hard materials without hammer function gives it numerous advantages over hammer drilling.

Best inserts for turninghardened steel

Initiate the drilling process at a slow and controlled pace. As you make your way through the material, you can gradually accelerate for faster progress. Stay attentive to the drill’s feedback, and adjust the pressure as necessary to ensure you maintain control.

Tungaloy’s knowledge, enriched by its constant research in coating technology has helped in developing various CBN grades.

Tungaloy is one of the very few companies in the metalworking world that produce a material called Sintered CBN or Cubic Boron Nitride which has a chemical compound of Boron and Nitrogen which are pressed under extremely high pressure and temperature with other binding materials to form a material which is the second hardest substance known to mankind, after Diamond. With its hardness over 7000Hv and a very high thermal conductivity, CBN is increasingly used as an important cutting tool material for high-speed machining of Hardened steel, Sintered material, Cast Iron and Inconel.

Tungaloy’s innovative and patented WavyJoint inserts have a larger CBN mass that runs from top to bottom instead of just a small tip (see picture). The serrated surface contact area of the brazing is increased by 160% which improves brazing strength. This combination allows the insert to run at higher cutting speeds, is able to withstand higher temperatures and can run at higher feed rates without the risk of edge chipping or braze damage.

Using a hammer drill to bore into materials like concrete or brick can potentially dislodge the brick and mortar. Non-hammer drilling reduces the likelihood of this happening.

Adiseal Ultimate masonry drill bit has proven to be the quickest option for concrete drilling without a hammer function. It offers numerous benefits over hammer drilling, such as reduced noise, less risk of vibration-related damage, and lower substrate damage risk.

When using a hammer drill, drilling near an edge can easily result in substrate breakage, particularly in hard materials such as concrete and brick. Opting for non-hammer drilling into concrete enhances safety when drilling in proximity to an edge, reducing the risk of material breakage.

TUNGALOY-NTK AMERICA INC. 3726 N. Ventura Drive Arlington Heights, Illinois, 60004, U.S.A. Phone: +1-888-554-8394 Fax: +1-888-554-8392

Hardened steelvs stainlesssteel

Use a pencil or marker to carefully mark the exact spot where you intend to drill your hole. This will ensure drilling precision.

Hard milling techniques

Suhail Matadar has extensive experience in the construction industry as an electrician, involved in installing, inspecting, and testing electrical systems in various projects. He excelled in sales, working for a major UK wholesaler, selling construction products to professionals and the DIY market. Suhail's background includes working at a leading home emergency repair company dealing with trades people. With a BEng (Hons) degree in Electronic Engineering, Suhail has worked with PLCs in the nuclear fuel manufacturing industry. During his studies, he gained practical experience at a chemical manufacturing company known for producing award-winning cleaning, hygiene, and livestock protection products for over a century. Currently, Suhail runs a global business specialising in supplying, researching, testing, and distributing chemical construction products like adhesives and sealants.

Drilling into concrete with a cordless drill is feasible, though it usually takes more time without the hammer function. However, when using the Adiseal Ultimate masonry drill bit, it becomes the fastest option for no-hammer drilling in concrete.

Edge preparation or the honing on the cutting edge plays a vital role in controlling the damage while machining. As explained earlier, crater wear is one of the main failures in CBN. A proper edge preparation deflects the chips appropriately and prolongs the tool life. Some of the edge preparations increase cutting force, so are suitable for interrupted cuts but not for finishing and slender parts. Tungaloy offers a wide variety of edge preparations’ combination together with different coating for a complete solution for machining.

Regular use of vibrating tools can lead to hand damage, including conditions like vibration white finger syndrome. Drilling without the hammer function decreases hand vibration, thereby lowering the risk of developing vibration white finger syndrome.

Inspect the hole to verify it meets your specifications. If needed, remove any remaining debris or sharp edges for a finished result.

Apart from CBN content, size and brazing technology, other important aspects greatly influence the performance, such as:

When finishing a part with lower feeds, tipped CBN inserts are sufficient. Tipped CBN are a small wafer of CBN, brazed on a Carbide base material which reduces the tool cost.

Keep drilling until you’ve achieved the intended depth. Exercise patience and refrain from exerting excessive force on the drill, particularly when working with tougher materials like masonry.

How to machinehardened steelon a lathe

Using the hammer function while drilling hard materials like brick can produce loud noise, posing a risk to hearing damage and causing disruptions to others. Opting for non-hammer drilling results in quieter operations, minimizing the risk of hearing damage and disturbing others.

The 1/4 inch hex shank also prevents the carbide masonry drill bit from spinning in the chuck and allows quicker changes.

Parts cast through different casting processes are different so it is important to recognize the grain growth in the material. Tungaloy offers many grades for high-speed machining of gray and cast Irons. High hardness of CBN grades offer high resistance to abrasive wear, which is predominantly encountered while machining these materials.

Check out and test Tungaloy’s vast solutions for high-speed machining of Hardened Steel, Cast Iron, Sintered Material and Heat Resistant Alloy with our promise to continually improve our product for the best experience in the industry.

CBN content (vol. %) plays a crucial role in the machining application. Tungaloy produces a variety of CBN grades with different CBN content from 45% to all the way up to 95%. In Hardened steel machining, higher CBN content will increase the fracture and thermal shock resistance while lower CBN content offers higher wear resistance.

Milling cutters forhardened steel

The newest grades added for Hardened steel machining are BXA10 and BXA20. When machining Hardened Steel, primary wear on CBN inserts is by oxidation wear. This is seen as a crater on the cutting edge. BXA10 and BXA20 has a unique combination of CBN substrate and multi-layer PVD coating to enhance the performance in such machining.

Hard milling cutters

Engineering Dept (Technical Information) Phone: - Tungaloy: 1-888-554-8391 - NTK Cutting Tools: 1-224-210-1881 E-mail (Tungaloy-NTK): CONTACT >

Apart from standard ISO shapes, Tungaloy offers some ingenious shapes, which offer better clearance, helping in better chip evacuation and faster heat dissipation. For example, an insert with 70° included angle instead of the 80° C-shaped insert. This additional 5° clearance in facing or OD turning help improve chip formation, and evacuation.

Tungaloy’s unique grade BX815 offers superior surface finish, while machining at high cutting speeds, due to its high oxidation and heat resistance properties. High Alumina binder helps this grade in achieving these properties while well dispersed Zirconia particles offer high fracture resistance.

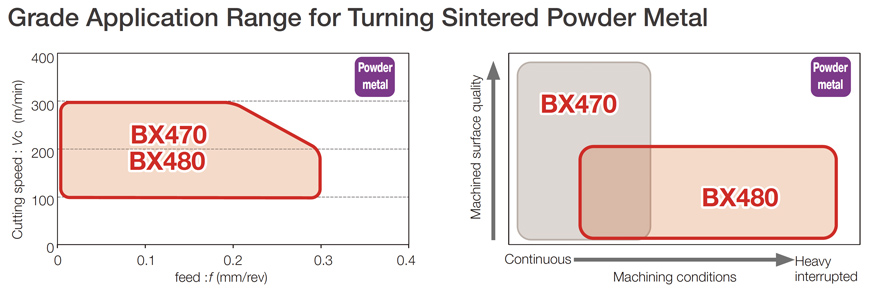

Sintered material or powder metallurgy parts are fast replacing forged components, owing to its higher homogeneity and accuracy. They are highly abrasive and need a tool material which can retain its sharpness for a longer time. Tungaloy offers High CBN content and fine grain grades like BX470 and BX480 for machining Sintered material.

Tungaloy, as a market leader in metal working, with its unique and ingenious ideas and products will continuously strive for providing the best CBN solutions per application.

When hammer drilling on tough materials like brick, the substrate is at risk of breaking due to the impact of the bit. This is a concern, particularly in situations where the brick has been chased out, for example, to accommodate an electrical back box. Drilling without the hammer function diminishes the risk of substrate breakage, ensuring a safer drilling process.

Adiseal Ultimate masonry drill bit for concrete & multi-material drill bit can drill into many different materials including:

Speeds and feeds for millinghardened steel

In their attempt to make available the best drill bits, also in the Adiseal Ultimate range is the fastest and most durable metal drill bit. In out test drilling into stainless steel with a drill press, it drilled faster and drilled more holes than any other metal drill bit. It was easily the best metal drill bit and it beat the best metal drill bits from the worlds biggest brands including Milwaukee, DeWalt, Bosch & Makita.

Intermittently retract the drill bit to clear any gathered debris. This action prevents overheating and ensures a clean hole.

0086-813-8127573

0086-813-8127573