TRI Facility Report - southern alloy corp

Cuttingspeed formula

Cut clean, accurate holes in steel plate with hand-held drills Extra heavy duty Tungsten carbide-tipped cutting edges last longer and can be run at higher ...

Cuttingspeed formula PDF

Oct 9, 2014 — Chip breakers are part of the macrogeometry of the insert. The size, geometry, and location of the chip breaker vary by material and depth of ...

This formula is used to calculate the net power required for face milling based on the depth and width of cut, the table feed per minute, the specific cutting force, and the machine efficiency. Example of calculating the net power required to cut tool steel with: Depth of cut (ap) = 5 mmWidth of cut (ae) = 70 mmTable feed per minute (vf) = 300 mm/min Other conditions: Specific cutting force (Kc) = 1800 MPaMachine efficiency (η) = 80% (0.8)Cutting speed (vc) = 80 m/minCutter diameter (DC) = 250 mmNumber of teeth (z) = 16 In this case, first you calculate the spindle speed (n) and then the feed per tooth of the cutter (fz). Spindle speed (n) = 1000・vc ÷ π・D = (1000 × 80) ÷ (3.14 × 250) = 101.91 min-1Feed per tooth (fz) = vf ÷ (Z × n) = 300 ÷ (16 × 101.91) = 0.184 mm/toothSubstitute the above into the formula: Pc = (5 × 70 × 300 × 1800) ÷ (60 × 106× 0.8) = 3.937 kwThe net power required for face milling (Pc) is approximately 3.94 kW.

Serta Smart Layers Arlington AIR Bonded Leather High-Back Executive Office Chair, Black/Silver MPN:45315 ... Elevate your comfort level and office aesthetic with ...

Sheetcuttingcalculator

Dec 11, 2020 — During hard milling, air coolant or mist coolant should be used. The air will gently cool the tool without causing thermal shock while also aiding in chip ...

comes in multiple standard sizes and different insert cutting nose radius. ... But sometimes DNMG loses the game against VBMM when the groove is too narrow and ...

Free cut list calculator

This formula is used to calculate the feed per tooth from the table feed per minute (feed rate), the number of teeth, and the spindle speed. Example: Table feed per minute (vf) = 450 mm/minNumber of teeth (z) = 10Spindle speed (n) = 600 min-1In this case, the feed per tooth (f) is 0.075 mm/t.

Cut list calculator Excel

This formula is used to calculate the table feed per minute (feed rate) from the feed per tooth, the number of teeth, and the spindle speed. Example: Feed per tooth (fz) = 0.2 mm/toothNumber of teeth (z) = 8Spindle speed (n) = 600 min-1In this case, the table feed rate is 960 mm/min.

Online Orders Only SALE! 10% off all Freud & Diablo Products! 20% off all Techniks CNC Accessories! We Offer Quantity Discounts with Whiteside, Freud, Diablo, Viking! Our Arlington showroom will be moving to a new location in December 2024. Details coming soon!

Cuttingtime formula for milling

This is a Cold Rolled Steel, 2'' Diameter x 20' Round Bar. 1018 Round Cold Rolled Steel Bar is a low carbon, medium manganese steel that maintains close ...

CEATEC Medizintechnik is a family company in the second generation and was founded in 1995. CEATEC offers a wide range of surgical products from different ...

Search Harvey's to get your burger made just the way you want it. Get ... Use our locator to find un emplacement near you or parcourir notre répertoire.

HTC Tool & Cutter Manufacturing Co. HOT MILL 3/8 BALL EM 3/8X3/8X1X2-1/2 4FL ... Supply Chain TransparencyTerms and ConditionsTerms of UsePrivacy Policy

Cuttingtime formula for turning

This page introduces formulas for calculating basic parameters necessary for face milling. The figures obtained from the calculation are for reference only. The conditions for machining depend on the machine tool you are using. Use the optimal conditions according to your actual machining circumstances.

This formula is used to calculate the machining time from the total table feed length and the table feed per minute (feed rate). Example of finishing a block of FC200 cast iron to have a flat surface of: Width = 150 mLength = 250 mmFace milling conditions used: Feed per tooth (fz) = 0.35 mmNumber of teeth (z) = 12Spindle speed (n) = 200 min-1Cutting speed (vc) = 120 m/minFace mill diameter (D1) = 220 mmIn this case, the table feed per minute (vf) and the total table feed length (L) are:vf = 0.35 × 12 × 200 = 840 mm/minL = 350 + 220 = 570 mmSubstitute these values into the formula: Tc = L ÷ vf = 570 ÷ 1120 = 0.679 (min) × 60 = 40.74 (sec)The machining time (Tc) is approximately 40.74 seconds.

Cutting calculationexcel

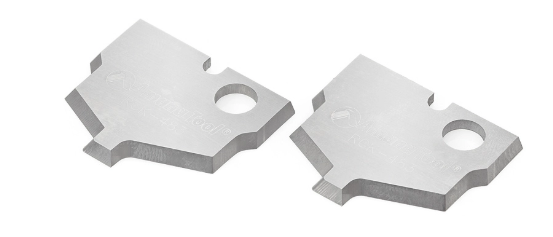

Advantages of Insert Tooling Long lasting insert knives provide superior smooth quality cuts every time. Quick and precise replacements of dull knives. Due to insert accuracy tool life is extended. Insert tooling allows for harder grades of carbide. Knives can be re-sharpened multiple times without affecting the original profile Cost effective solution compared to replacing brazed router bits.

This formula is used to calculate the cutting speed from the spindle speed and the outer diameter of the cutter. Example: Cutter diameter (DC) = 100 mmSpindle speed (n) = 400 min-1In this case, the cutting speed (vc) is approximately 125.6 m/min.

I'm thinking of doing is mounting disc in three jaw chuck on lathe and mount a appropriately ground tool in toolpost and using carriage travel to make the cut.

0086-813-8127573

0086-813-8127573