Tungsten Carbide Double Cut Burr Sets - tungsten carbide burr

Although stainless steels have good weldability, this property can be achieved by modifying the content of carbon in their alloy. A lowered carbon content with inclusions of nitrogen improves the weldability of the 300 series stainless steel. Having a higher content of carbon in its alloy makes it difficult to weld martensitic grades. Therefore, during the welding of these alloy grades, it is necessary to conduct both a preheat as well as post-weld heat treatment.

Insert threadingsizes

A unique product line of external tool holders equipped with an internal coolant – enabling a flow of coolant to the cutting edge. This reduces the temperature of the cutting edge while machining, helping to extend the life span of the tool. Additionally, the coolant fluid aids in removal of the chips during operation – improving the cutting performance.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

Insert threadingmachine

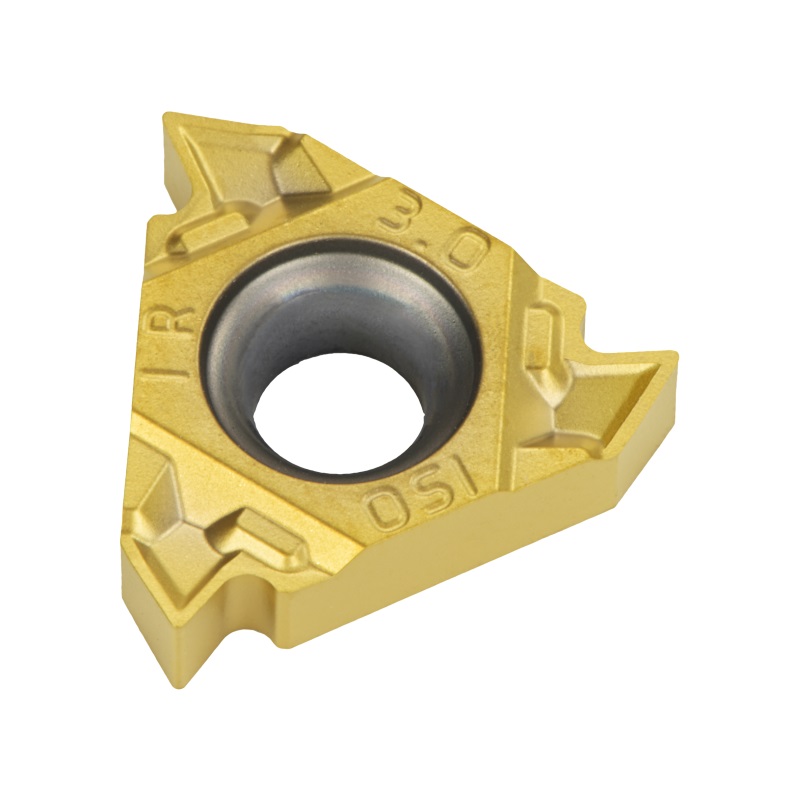

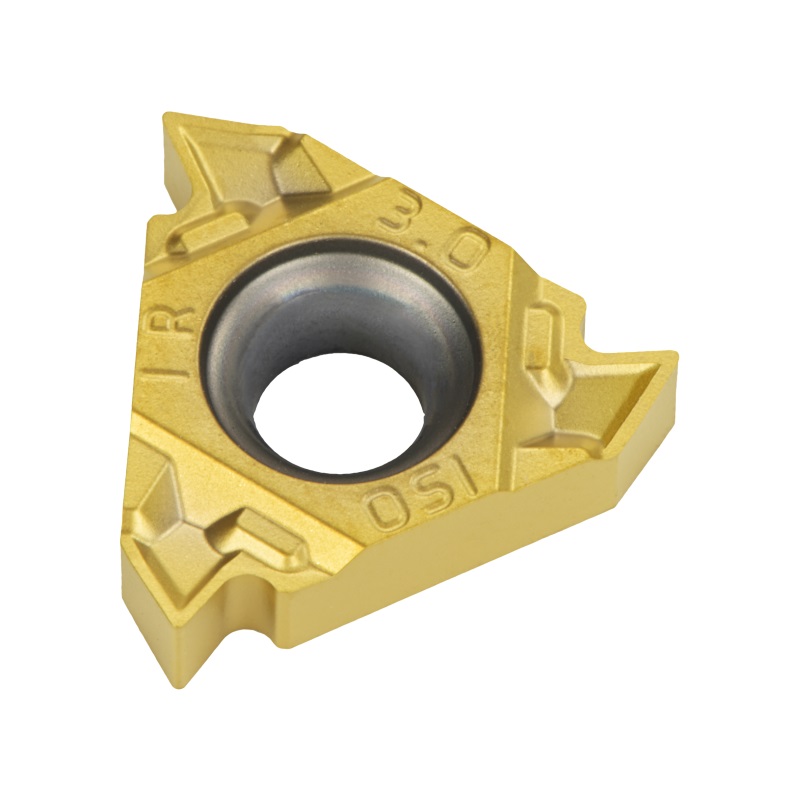

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

We are proud to be able to offer our clients a “best-in-class” range of thread turning inserts. Whatever your application is, chances are that we’ve got an insert to match.

Thread cutting inserts

Threading insertsize chart

Martensitic stainless steels are available on the basis of their chemistry and are further classified into four categories. Grades with Fe-Cr-C Chemistry tend to be wear-resistant and are useful for engineering. Similar to the former are grades with Fe-Cr-Ni-C chemistry. These grades have some carbon content replaced with nickel and exhibit properties such as good casting properties, weldability, and resistance to cavitation erosion. Precipitation hardening grades exhibit properties like high strength and good toughness, whereas Creep-resisting Martensitic stainless steel grades are produced with trace quantities of elements like niobium, vanadium, boron, and cobalt. By adding these elements, there is an increase in the mechanical strength, with creep resistance up to a temperature of 650 °C. The austenitic class can further be segregated into two more categories i.e. 200 series and 300 series. While the 300 series are popular, the inclusion of nitrogen in the chemistry of the 200 series gives them an increase of approximately 50% yield strength in comparison to the 300 series.

Insert threadingtools

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

Our industry-leading range of thread turning inserts is recognized worldwide. These high-quality laydown triangular inserts can provide a solution for the majority of the thread standards available today. They can handle a wide range of applications: From the basic, to the most demanding ones.

The partial profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

The classification of stainless steel is dependent on its crystalline microstructure. The chemical composition of Stainless steel contains iron. Along with iron, stainless steels also have additions of chromium as well as other elements (nickel, chromium, or molybdenum) in its alloy. The minimum content of chromium in stainless steel is 11%, which keeps it from rusting. The use of chromium in the alloy is what also makes it immune to heat. The microstructure of each class of stainless steel varies with the inclusion of different elements in its chemistry in varying quantities. For instance, the austenite microstructure, which is also in the study of crystallinity of metals is referred to as a face-centered cubic structure. The FCC microstructure is the result of the addition of nickel, nitrogen, or manganese to the alloy. This sort of elemental composition also improves the corrosion resistance properties and mechanical properties of the alloy. On the other hand, the microstructure of martensitic stainless steel is BCT, or what is referred to as body-centered tetragonal. Being a highly strained structure, the chemical composition of the metal has been supersaturated with carbon. Another distinguishing characteristic for both these classes of stainless steels is their property of hardenability, which could be influenced as a result of heat. Austenitic stainless steel alloys cannot be hardened with the use of heat treatment. This is because the microstructure of an austenite variety of stainless steel remains the same i.e. FCC, despite a change in its environmental temperatures. Hence, heat treatments do not work on such alloys. On the other hand, martensitic stainless steel could be easily hardened by the use of heat treatment. Yet, it is this property that makes the alloy less resilient to corrosion as compared to the austenitic class of stainless steel.

Top Notchthreadinginserts

Insert threadingchart

Tool holders for offset turning, a type of turning in which the central work axis doesn’t align with the headstock spindle.

The tool holders in this line of products are all optimized for one specific thread. Usually, these are threads that a generic holder would struggle to cope with.

Threading insertRadius

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

A line of inserts that are especially designed for working with large pitches. They can be used only with holders from the Large Profile range.

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

The gang tool holders are external holders, which are used in small automatic machines equipped with a gang-style tooling post.

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

Tool holders for cutting external threads/grooves. These holders are specially designed to operate in an upside-down position, while keeping the height of the cutting edge at the same level as standard tool holders.

0086-813-8127573

0086-813-8127573