Tungsten Carbide Inserts - Abrasive West LLC - carbide inserts manufacturers

Thread mills are made from solid carbide and most machine taps are made from HSS (high speed steel). However, thread mills will last much longer than taps, reducing downtime, and they will not break and get stuck in the hole like a tap can. Thread mills can be a much more cost-effective solution than machine taps, especially in difficult materials or applications.

Laser beam machining uses high energy light beam to melt and remove the workpiece material. LBM machining operations, like laser cutting, can work on all types of materials. These types of machining operations are usually applied on materials with poor conductivity because of the limitations of EDM and other electrical methods. Applications of LBM machining operations are:

Machining operations have many different types to suit various requirements. These different types of machining processes are:

The boring operation is used to enlarge a pre-drilled hole. The enlargement is done with a single-point cutting tool. Initially, a small hole is drilled with the help of a drill press or any other alternative. Boring tools can be mounted on lathes, milling machines, and drill presses. Applications of boring are:

Distinguish betweenconventionaland unconventional Manufacturing process used in Industries

There is no hard and fast answer to this question. Some thread mills are far faster than standard machine taps, some high-performance machine taps are faster than thread mills. It depends entirely on the application and the tools being used. However, thread mills are far safer to use than taps and can prevent scrapping of workpieces due to broken tools.

There are plenty of differences between conventional machining and non-conventional machining processes. Here is a complete list of these differences:

Electro chemical machining combines the chemical machining process with electrical energy. This process is the opposite of electroplating. This process is independent of surface hardness and machinability. Therefore, it can be used to machine hard materials with ease. It is also good for machining materials with poor machinability. Applications for ECM are:

Reaming is used to enhance the quality and precision of holes. Reaming operations are used for the secondary finishing of workpiece holes. It can make the hole diameter more accurate, round, and with a smooth surface finish. Reaming utilizes multi-point cutting tools. Reaming machine is called a reamer. The reaming process follows holes created by drilling or boring. Applications of reaming are:

Non conventional machining process does not use traditional cutting tools. Instead, these machining techniques utilize heat or force for material erosion. Non conventional machining processes are more modern with high precision. Let us go through these various types of machining operations:

Indexable thread mills are generally for larger diameter threads, however there is a cross over between solid and indexable thread mills at around M16. Solid carbide thread mills will offer greater rigidity (indexable tools and mainly HSS shanks), often have longer flute lengths and more flutes, so they can be faster than most indexable thread mills. However, they can also be very expensive compared to indexable thread mill inserts above M16. Indexable thread mills offer the flexibility of being able to machine different thread forms and pitches with one holder. This makes them a very cost-effective solution. They are also exceptionally cost effective for large diameter threads. Some indexable thread mills are available with multiple inserts for higher performance applications, or with very long holders for long reach applications. In summary, it depends entirely on the tools being used and the application. For help and support in choosing whether to use a solid carbide thread mill or indexable thread mill, please contact our technical support team on 01924 869665.

Lapping process is used for secondary finishing operations on a workpiece. In lapping, the workpiece surface rubs against the lap plate. There is an abrasive paste or powder placed between the two surfaces. Lapping averages the rough features of the workpiece surfaces, leading to smooth edges. Application of lapping is:

The milling process utilizes a high-speed rotary cutting tool against a stationary workpiece. It works on an automated or manual milling machine. The cutting tools in milling machines have various shape options. Based on the variation of cutting tools, there are many different types of milling operations. Common examples are end milling machine, face milling machine, knee milling, etc. Applications of milling machines are:

Conventionalmachining process pdf

Conventional machining processes are the traditional machining processes. These processes use physical tools like cutting blades and drill bits to accomplish the machining action. The different types of conventional machining processes are:

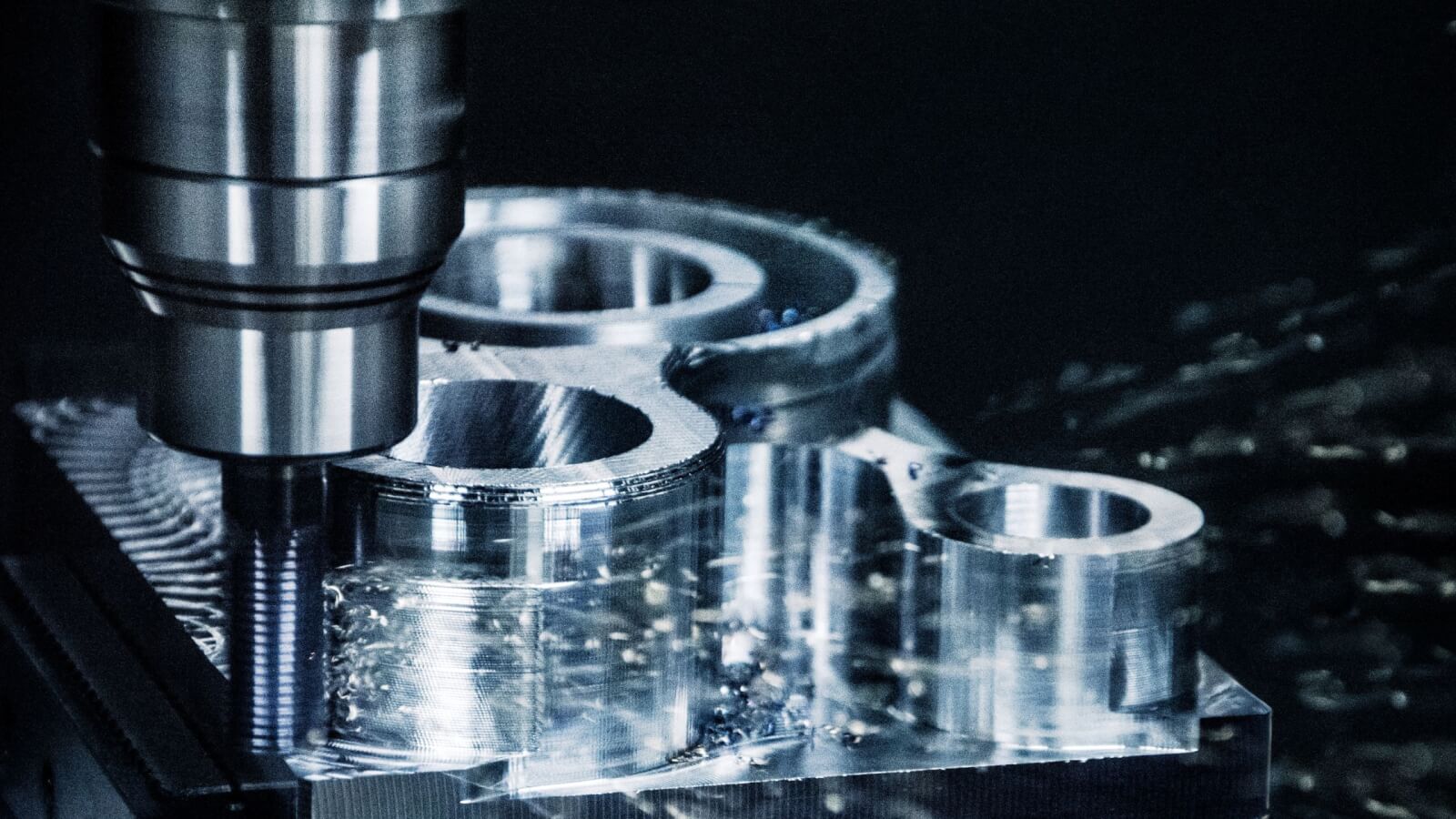

CNC machining

We know that speed of delivery is so important to customers, we will ensure your enquiry is sent to our most trusted manufacturers to ensure we can achieve the best delivery time for you.

Ion Beam Machining is a surface finishing process. It alters the structure of the workpiece on a molecular level. Ions are accelerated and made to collide with the workpiece. The high velocity ions alter the material molecules on the workpiece surface. Applications of Ion Beam Machining process are:

Conventional and non-conventional machining operations can provide better results than any alternative. The choice between the different types of machining operations will depend on priorities such as costs, precision, and cutting speed you require. Based on the information presented above, you can decide which machining operation will provide the best result for your needs.

Abrasive jet machining uses abrasive particles to remove material from the workpiece. A high-speed stream of gas provides energy to the abrasive. Abrasive jet machining is known by many other names like pencil blasting, abrasive micro blasting, and micro-abrasive blasting. The applications of Abrasive Jet Machining are:

Conventional machining operations rely on metal alloy cutting tools. Commonly used cutting tools are made of carbide steel or high-speed steel. However, non-conventional machining operations rely on other means. For instance, cutting action in these techniques can be achieved by water force, electrical heat, chemical reactions, or friction of abrasive particles.

The non-conventional machining process is generally far more accurate than conventional alternatives. In non-conventional machine operation, the thickness of the cutting medium can be narrowed down to extreme proportions. For instance, the laser beam or electrical arc is smaller than the thickness of a human hair. This leads to extremely precise cuts with little kerf width.

Tapping cutting tool is used to make internal threads on the work material. The cutting tool itself is called the tap. Tap can have a cylindrical or conical shape. The tap rotates and moves inside the workpiece linearly. This results in the thread formation on the internal periphery of the workpiece. Holes are pre-drilled on the workpiece with drilling or boring. Application of tapping are:

Thread mills are a high precision tool yet most customers use them in ER collet chucks and without through coolant. By using a hydraulic chuck, shrink chuck or any other holder with <0.003mm run-out, you will reduce vibration and therefor tool life and thread quality. Secondly, by using a through coolant thread mill it clears the chips out of the hole and prevents ‘double cutting of the swarf’ which can damage or mark the threads.

Machining is a manufacturing process that removes material in a controlled manner to produce the required part. Therefore, machining is also known as a subtractive manufacturing process. The workpiece is always bigger than the required part. Machining processes have a higher precision than alternatives like additive manufacturing techniques.

Broaching uses a toothed cutting tool to remove material from a workpiece. The tool used in broaching is called a broach. Broach takes a minimal amount of material from a workpiece in a single pass. It is applied for making niche features in a workpiece. Broaching commonly makes parts like:

Conventionalprocess meaning

Many modern CNC machine tools come equipped with a thread milling cycle, however if your machine does not have a pre-programmed thread milling cycle that does not stop you from thread milling, however your CNC machine does need to be capable of simultaneous 3 axis machining. If your machine does not have a thread mill cycle, you can simply use the Vargus GENIUS software which will generate your thread milling programme for you for whatever machine control you require.Why are thread mills more expensive than taps?

A conventional machining operation can be difficult when working with materials of poor machinability. A hard material will create excessive tool wear with these machining techniques. However, non-conventional machining operations can easily remove material from the toughest workpiece. Therefore, these processes are preferred for materials with high hardness or poor machinability.

Machineoperation

Chemical machining uses chemical reactions to remove material from the workpiece. This process is also called Etching. The material removal occurs by dipping the workpiece in a chemical agent. The workpiece is masked, and the areas to be removed are left unmasked. This process can create thorough cuts as well as engraving. Applications of chemical machining process are:

Drilling is used to make holes in a workpiece. The holes are used for screws or aesthetic purposes. Drilling operations are the most common type of machining process. Drilling is carried out on a drill press. Drill presses can be manual, or CNC machine mounted. The cutting tool is called a drill bit. Applications of drill press are:

Precision machining is a process used to remove material from a workpiece while holding close tolerance finishes. The precision machine tools typically used in this process include CNC milling machines, lathes, and grinders. Precision machining process is crucial for producing intricate parts with a high degree of accuracy and smooth finishes, often to tolerances measured in micrometers or even nanometers.

ECM machining

Our internal technical support team or external applications team are available to support you in your thread and groove milling applications. Contact us now for support on:

Electrical Discharge Machining (EDM) uses electrical pulses of high voltage frequency for cutting the workpiece. The pulses generate electrical arcs that melt the material at the required location. This results in a highly precise cut. This method applies to cutting conductive materials only. Applications of electrical discharge machining are:

Types ofconventional machine

Conventional machining operations are less expensive than non-conventional alternatives. Non-conventional machining relies on complex equipment that requires a high initial investment. Additionally, the operator for non-conventional processes requires a special skill set. The conventional machining process is usually simple, requiring no specialized operator skillset.

Planing is used for machining a complete surface in a single pass. Planing machines can smoothen an entire surface of a workpiece. It can also create inclined surfaces. Planar cuts can also create niche features on surfaces. Applications of planing are:

Coated carbide thread mills for general thread milling applications. Helical flutes spread the cutting load & reduce vibration.

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

Machining operations run most of the manufacturing processes worldwide. They either create the final product completely or make the tools needed for manufacturing. Therefore, understanding machining processes is key to the skillful execution of your next manufacturing project.

This depends entirely on the application, machine tool, material or budget. Thread mills have many benefits over taps, however on some applications taps can be faster, more cost effective and easier to programme than thread mills. For help and support in choosing whether to use a thread mill compared or a tap please contact our technical support team on 01924 869665.

Knurling is a surface finishing process. It creates a pattern on the workpiece surface. The pattern can be vertical lines, horizontal lines, or criss-cross grids. Knurling can be done for aesthetic reasons and practical purposes. It utilizes a knurling pin rolled against the workpiece surface. Applications of knurling are:

Sawing uses a cutting tool for slicing through the workpiece. The cutting tool can be abrasive or have toothed bands on the blade. Sawing is used to divide a workpiece into small parts. It is not as accurate as other machining processes. Applications of sawing are:

Drilling is the most common machining process. It is used in secondary processing after every other machining operation. Similarly, grinding is also very common due to its secondary finishing application. Among primary machining operations, turning and milling machines are very common.

Shaping machine is a fast way of altering the basic shape of a workpiece. It uses the reciprocating mechanism between the cutting tool and the workpiece. The workpiece moves back and forth against the cutting tool. Shaping can generate flat surfaces, inclines, and even curved surfaces. Applications of shaping are:

The material removal rate in conventional machining operations is higher. This is because of a higher tool contact with the workpiece. It also leads to faster tool wear. In non-conventional processes, the material removal rate is slower.

A conventional machining process has limited accuracy. This is because of the limitations on the minimum thickness of the cutting tool. However, non-conventional machining processes are highly precise. This is because the thickness of laser, water, or electrical arcs can be narrowed down to a microscopic level.

Difference between CNC andconventional machine

Waterjet cutting is a cold-cutting non-traditional machining process that uses the force of high-pressure water with a very narrow stream. The water stream can pierce through hard materials as well as softer materials with ease. Abrasive particles are often added to the water to speed up the cutting process. Applications of water jet machining are:

Plasma arc machining uses a high-velocity ionized gas. The ionized gas creates a plasma arc that melts the workpiece at the desired location. The high-speed stream of air blows away the melted material. This results in a clean and highly precise cut. Applications of Plasma Arc Machining operations are:

Micro machining is a precision engineering process where components are created on a micron scale. It involves various techniques, each tailored to specific materials and applications, allowing for the production of intricate and detailed parts. Here’s an overview of common micro machining methods and their applications:

Thread milling has become an increasingly popular alternative to tapping and thread turning for many applications due to the advantages that it delivers. Whilst it is not suitable or cost effective for every application, it has many benefits compared to tapping or thread turning:

This article will discuss in detail the various types of machining operations. You can choose the right fit for your requirements based on the information provided here.

Ultrasonic machining uses a high-frequency vibrating tool to remove workpiece material. There is the presence of abrasive material between the tool and the workpiece. The abrasive material is mixed with water to create a fine abrasive paste. The tool vibrating at high frequency uses the abrasive paste on the tip to remove the material. Applications of ultrasonic machining are:

In turning, a workpiece rotates around a central axis. The cutting tool is stationary and removes symmetrically from the workpiece’s surface. Turning operations are generally performed on cylindrical and conical shaped objects. The workpiece can be hollow or solid. Some applications of the turning process are:

Conventional cutting processes are faster than non-conventional options. This is because the cutting tool can contact and remove a large area of the workpiece. Non-conventional processes have to melt or erode the workpiece on a particle level. This leads to a slower cutting speed.

Grinding is a secondary finishing process for improving the surface finish. It uses an abrasive rotary disc called a grinding wheel. Grinding processes can smooth the defects caused on a workpiece due to other machining processes. Surface grinders can also improve the dimensional accuracy of a workpiece. Application of the grinding machining process are:

The conventional machining process utilizes a solid cutting tool. Therefore, it is limited in the type of shapes it can produce. Usually, these methods are applied for machining simple shapes. However, non-conventional machining operations can machine shapes with high complexity.

0086-813-8127573

0086-813-8127573