Tungsten Carbide Material Properties - melting temperature of tungsten carbide

The most important part of the tool is your drillbits. I don’t mean the strength of them, bar the few occasions you are drilling metal, even the cheapest bits should be able to drill plastic just fine.

Unfortunately, 2.0mm is the maximum size (you could maybe squeeze in a 2.1mm or 2.2mm). but you cannot use the standard 3.2mm PCB Drill Bits with these.

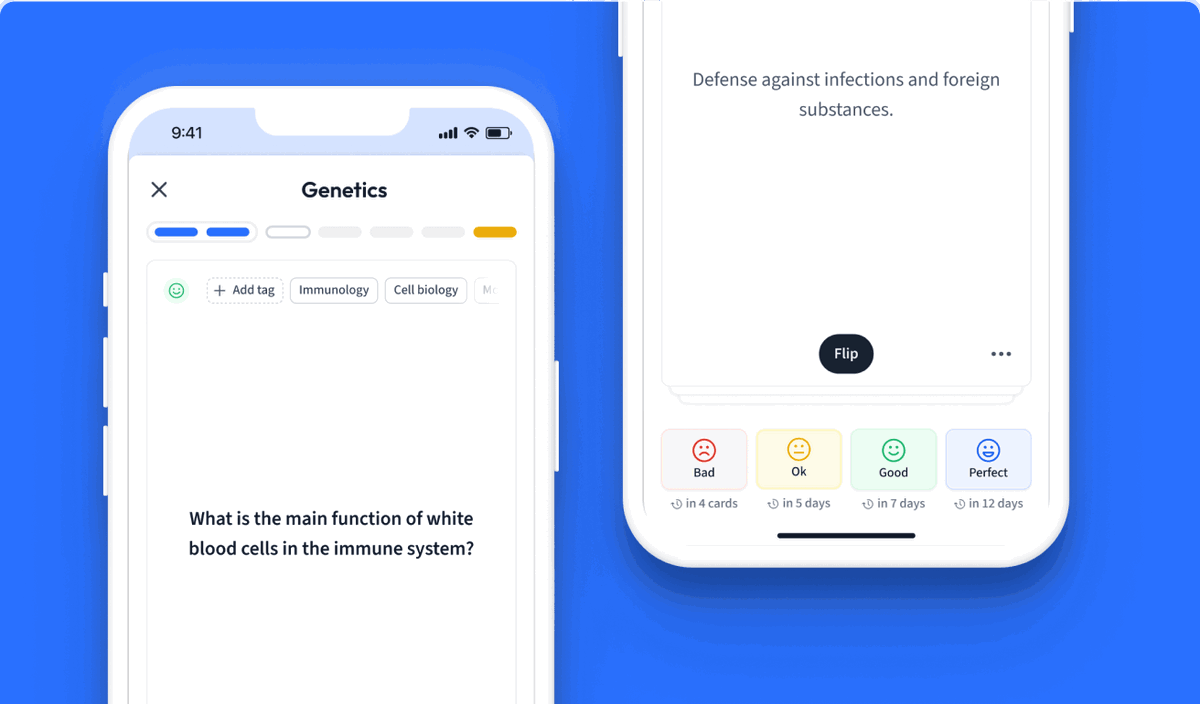

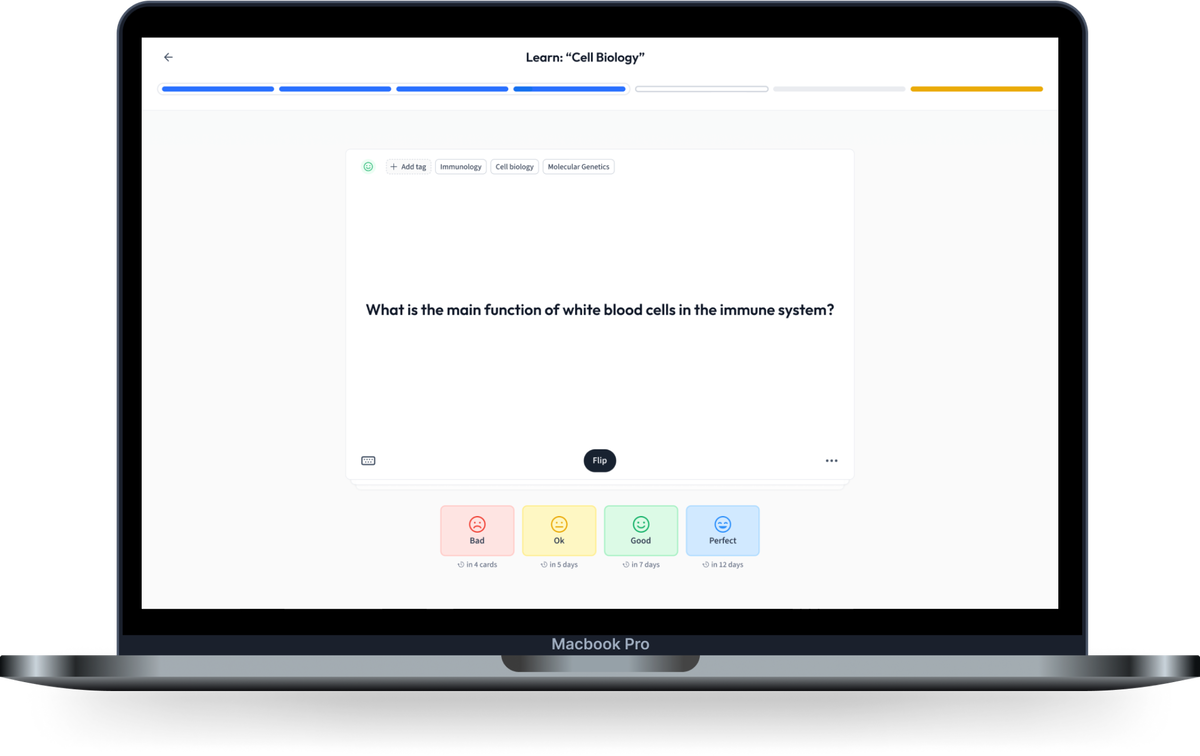

StudySmarter is a globally recognized educational technology company, offering a holistic learning platform designed for students of all ages and educational levels. Our platform provides learning support for a wide range of subjects, including STEM, Social Sciences, and Languages and also helps students to successfully master various tests and exams worldwide, such as GCSE, A Level, SAT, ACT, Abitur, and more. We offer an extensive library of learning materials, including interactive flashcards, comprehensive textbook solutions, and detailed explanations. The cutting-edge technology and tools we provide help students create their own learning materials. StudySmarter’s content is not only expert-verified but also regularly updated to ensure accuracy and relevance.

The choice of cutting tool materials significantly affects the industrial operations in terms of cost, quality, and efficiency. These materials are selected based on several critical factors:

Wear resistance is an essential property for cutting tools, as it determines how long a tool maintains its effectiveness. Tools with high wear resistance suffer less damage over time, ensuring longevity and precision in machining. Wear can be minimized through proper tool coating and selecting materials that experience minimal friction. Meanwhile, thermal resistance refers to the ability of the material to withstand high temperatures without losing its toughness or hardness. This property allows tools to function effectively at higher speeds, leading to increased productivity. By using materials like ceramics and cubic boron nitride (CBN), you achieve superior thermal resistance.

Consider machining a gearbox component. Carbide tools provide fast processing and durability, ensuring efficient production of accurate and quality gears, crucial for the performance of vehicles.

While diamonds excel in cutting hardness, they should not be used with ferrous materials as the high temperatures during cutting can cause chemical wear.

Hardness is a measure of a material's ability to resist deformation, indicating how well a cutting tool can maintain a sharp edge under pressure. Toughness, on the other hand, ensures the tool can absorb energy without fracturing, crucial for enduring the sudden forces during cutting. Together, these properties ensure the tool doesn’t wear down quickly or break during operations. The relationship between hardness and toughness of a tool material is often inverse, which presents a challenge when selecting materials. So, tool materials must strike a balance between these two properties.

Chemical stability is the ability of a cutting tool material to resist chemical reactions with the workpiece material and the environment during machining. Reactive materials tend to degrade faster and can compromise the precision of the cut. Materials with high chemical stability, like diamond and CBN, can cut through materials without deteriorating or reacting with them.

FauxHammer.com is dedicated to finding the best tools for your hobby. Start with our list of Essential Hobby Tools which will lead you to find the Top-10 tools for each category.

Utilizing specific cutting tool materials in various industries offers numerous benefits, enhancing both manufacturing efficiency and output quality. By selecting the appropriate tool material, you can significantly influence productivity and operational cost-effectiveness.

Search Pin Vise on Amazon or eBay and you’ll find these. They are a cheap option and come with a load of drill bits. They are generally fine and do the job. They don’t use collets and instead have a more typical drill chick which will hold any size up to 3.6 mm.

Collets are like a traditional chuck except the are a fixed size. Usually, a Pin Vise comes with 2 two-sided collets. One collet is in the front of the drill as it is in use, the other is stored in the handle until you need it. Each has 2 fixed diameter holes for a total of 4 different sizes. Each hole will hold a small range of different sized drill bits. If you need to change to a much large or much smaller bit than the one that is currently fit, you need to use the other side of the collet or the other collet.

That’s when I found PCB Drill Bits. These bits are for drilling Printed Circuit Boards in electronics and computing projects. They come in sizes from 0.1mm (insanely small) to 3.2mm (too big) in diameter, are cheap and are usually made from Tungsten Carbide. I’m not sure if you’ve ever played Rock-Paper-Scissors-Tungsten-Plastic. But Tungsten beats plastic, and pewter too. Perfect! Although the finer sizes can snap easily when compared to steel – so, be a bit careful with them.

Diamond Cutting Tool: A tool specifically designed for cutting materials using diamond components due to their exceptional hardness.

For Miniature Painters, Modelers and Hobbyists., Dedicated to Tools, Techniques and Tutorials you can use to improve your hobby.

Self-appointed Editor in chief of FauxHammer.com - But I need to thank the team for existing and therefore enabling me to give myself role - without them, I'm just a nerd with a computer and a plastic addiction.

Let’s get this out of the wat straight off the bat, you can use a Dremel or any rotary tool. They are absolutely great for a myriad of tasks, but they are overkill for drilling holes in miniatures. Unless you are incredibly precise, you are likely to slip and worse drill a hole in your hand.

The hexagonal grip that you turn isn’t the best either IMHO. With only 6 flat sides there isn’t really a grip. It does, however, have the best look of any of the hand drills and will be great sat next to a set of Citadel tools. The strangest thing is that this comes with only one two-sided collet, even though the handle unscrews from the body to house a second. (I suppose you could store your extra drill bits here instead)

Tool wear can be expressed mathematically through equations like the Taylor Tool Life Equation, which predicts tool life based on different factors: \[ VT^n = C \] In this formula:

The only drawback is that the maximum drill bit diameter is 3.0mm, you can wedge in a 3.2mm PCB Drill Bit. But it is a wedge and you have to drag them out. If you are happy to swap out the collets all the time for changing drill bits, it’s a great choice.

This is my baby, I had this model for over 20 years and they still make them now. It is generally everything you want from a typical pin vice. Solid build, decent size and weight. smooth spinning motion. It comes with 2 two-sided collets. one is stored in the handle one is stored in the front.

Fibula with Spiraled Ends – Brass - LB ... This item is in stock and ready to be shipped. *Make sure all the items in your order are in stock to get it delivered ...

Please Note: This site uses affiliate links. Our Affiliate Partners are shown below (Affiliate links will result in compensation to the site on qualifying purchases) Click this link & buy your hobby stuff from Element Games for the UK & Europe to support FauxHammer.com – Use Code “FAUX2768” at the checkout for double reward points.

Ih - Insert Hand: Right. Thft - Thread Form Type: M60 - Iso Metric 60°. Tpt - Thread Profile Type: Full. Tctr - Thread Tolerance Class: 6H. Insl - Insert ...

Consider an application where highly hard materials like carbide are used for high-speed cutting tasks. Carbide can provide excellent performance due to its hardness, but it requires careful handling to avoid chipping.

In the heart of Nashville, Weiss Watch Company is redefining American watchmaking. Each timepiece is handcrafted using the finest materials, and is individually ...

If I could find more adjustable options I would have included them. Yeah I hate mucking about with the collets. But the main point was that if you get the Tamiya Pin vise and the PCB drill bits. No mucking about needed.

Diamond is recognized as the hardest naturally occurring material, making it highly suitable for cutting operations requiring extreme hardness. Diamond cutting tools are typically used in the machining of non-ferrous materials, ensuring a high-quality surface finish and precise dimensional accuracy. These tools are ideal for applications such as:

FauxHammer.com is dedicated to finding the best tools for your hobby. Start with our list of Essential Hobby Tools which will lead you to find the Top-10 tools for each category.

I originally held a guide here on drilling gun barrels but it made this post way too long. Instead, I’ve put that guide elsewhere and you can view it by clicking here. it does tie in nicely with this article.

The handle is the part which rests in your palm and allows you to hold the PinVise steady as you spin the rest to drill a hole. not all hand drills come with this but I find it to be the most necessary component.

Diamond tools offer exceptional wear resistance but are not suited for cutting ferrous materials due to chemical reactions.

This head, however, is larger than most Pin Vise heads and does get in the way a bit of you are drilling areas where other parts of the model it in the way. The other annoyance (and it is just an annoyance) is that the handle wobbles a bit squeaks like hell.

Despite the advantages of diamond tools, there are notable trade-offs to consider. One of the main considerations is thermal conductivity, which allows heat to dissipate efficiently, benefiting high-speed operations. However, their chemical reactivity with iron-based materials limits their use. Another fascinating aspect is their wear mechanism: diamond tools wear down primarily through attrition and micro-fracturing, which retains the cutting edge's sharpness over time. This makes them particularly adept at intricate and lengthy cutting tasks. Consider the equation for calculating force during cutting with diamond tools: \[ F_c = A \times k \times f \] where:

Sterility and surface finish quality are essential when selecting cutting tool materials for medical applications to ensure patient safety and functionality.

In aerospace applications, cutting forces and heat generation can be analyzed to optimize cutting parameters and improve tool life. Consider the formula:\[ F = k \times A \times V \times T \times D \] where:

The Citadel Drill is one of the most well-known hand drills in this community. It’s generally pretty good. It’s well built with a smooth turning motion. I don’t find the triangular-shaped handle the most comfortable, but that’s likely just a personal view as I’m used to a different type of handle.

The aerospace industry demands cutting tool materials that can handle tough materials like titanium and nickel alloys, often used in manufacturing aircraft parts and turbines. High temperature and pressure conditions require tools with excellent thermal stability and wear resistance.The use of ceramic tools allows for higher cutting speeds, whereas diamond tools achieve supreme surface finishes and tolerances. Applications include:

Find Hex-Shank 1/4-in drill bits at Lowe's today. Shop drill bits and a variety of tools products online at Lowes.com.

I currently use one of those generic ones and the fact that you can just pop out the drill bit and just screw or unscrew the end to fit a different size is great! I don’t think I could ever deal with fluffing about with collets.

The most common thing we all drill (Space Marine Gun Barrels) it makes sense to drill the side holes with one diameter drill bit and the front of the barrels with a slightly larger drill bit. It’s a subtle change, but one that makes it appear just slightly more real.

The issue I have with Pin Vises and drill bits is that I love the low profile of a typical Hobby Drill that uses collets. The issue with collets is that the difference in drill bit size means changing around the collet configuration every time you swapped the drill bit. More annoyingly, I had to swap to the other collet so I had to unscrew both the chuck and the handle, every time. You know if you’re painting an army, this is just frustrating. A minor annoyance that after time really grates.

By signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Cutting tool materials are substances used in the manufacturing process to cut or shape the workpiece. Their main purpose is to withstand the extreme mechanical and thermal stress during cutting, ensuring high precision and a smooth finish.

The best part of these, however, is that the shank (the bit your drill holds) is a standard size. so long as you get a Pin Vise which holds 3.2mm drill bits, which is the standard shank diameter for PCB Drill Bits.

I’ve had the same Hobby Drill for over 20 years, it’s never let me down (until it did). When I say mine broke. it’s because I spilt glue on it and it seized the handle. Less “it broke”, more “I broke it”. It’s the sort of tool that you will buy once. so if you are in the market for one, make it a good one. They aren’t expensive at all. But they can be “cheap” in every sense of the word (we’ll get to that in the list).

This is a somewhat valid option, for a while. you can use a good sharp hobby knife in a twisting motion to carve out a hole. used gently it will work for gun barrels. The front hole at least. the side holes will likely just get mangled. It’s imprecise. and you will quickly snap the point of your knife making each new hole worse. But it can be done.

Harvey & Company is a leading buyside acquisition search and principal investment firm that has been involved in over 700 transactions, including 151 in ...

Machining Images is your go-to resource for high-quality stock images related to machining, manufacturing, and industry. Our collection includes a wide array of ...

Pre-Cut Wheels · Tool Holders · Finger Bits · Full Pass Finger Bits · Incremental Finger Bits · Calibration Wheels · Core Bits · Suction Cups · Fluting ...

You may find some of these online, the shaft is similar to that of the plunger on a child’s spinning top toy. As you push down the grip on the handle it will spin the drill. Like a Dremel, these are overkill for plastic miniatures. but they are still useful as you can just turn the handle like a normal Pin Vise.

It’s long-lasting and inexpensive. It typically comes with 5 assorted drill bits, but it never indicated on the packaging what size these are. I can’t find it online either. but they were always plenty enough to drill my gun barrels on space marines.

Whether you are looking for a Hobby Drill, Hand Drill or its correct moniker Pin Vise (I didn’t know this originally either). You’re likely looking for the same thing. a tool to drill holes into your models. Today we are looking at finding you the best Pin Vise for your Models & Miniatures.

It finally happened, my Pin Vise broke. For those of you who only know the pain of spilling a pot of Agrax Earthshade, you can’t understand the loss of a hand drill. It’s been a part of my kit for over 20 years, one of the oldest tools I owned and it’s dead. I’ve spent the last month looking for a new one. I ended up buying a few to test them out.

Please Note: This site uses affiliate links. Our Affiliate Partners are shown below (Affiliate links will result in compensation to the site on qualifying purchases) Click this link & buy your hobby stuff from Element Games for the UK & Europe to support FauxHammer.com – Use Code “FAUX2768” at the checkout for double reward points.

A Pin Vise is a relatively inexpensive piece of your hobby kit, but there are certainly some benefits to splashing out that extra cash. If you are a Warhammer collector and want all the tools to match. there’s nothing wrong with their set. If you are looking at a more budget-friendly option I’d suggest either The Army Painter or Modelcraft versions which come with drill bits. The cheapest option is a generic Amazon or eBay model and these are absolutely fine for doing the job. I just found some annoyance with them like how squeaky the handle was as it spins.

My search for a better Pin Vise started with better drill bits, or at least a way to change bits without fully reconfiguring the whole Hobby Drill.

The first of our known hobby branded options is The Army Painter Pin Vise. this one is great and well built. It does use collets however these are only 1 sided and there’s one for each of the different sized drill bits you get with it. The drill feels a bit short in my opinion but is still comfortable to hold and it has a smooth mechanism. The handle is fastened in with a rubber ring and just pulls off to access the internal storage.

And now onto the list, I normally do a top 10, but I am limited to options, these are also pretty cheap to buy, no matter what model you get. so the price doesn’t really come into it. The below options are all the ones we looked at specifically. If you think there is another option worth considering, let us know.

As I’ve said above, the best option, at a comparable price to the Citadel Pin Vise is the Tamiya Extra Fine which comes in a fully metal version or rubberised handle version. As the most important part of any drill is the bits you use. the convenience of being able to add standard drill bits with a 3.2mm shank just makes things so convenient by not having to keep changing collets to swap drill bit sizes. So anything which houses a 3.2mm shank is worth an investment.

It has 2 collets. one is stored in under the handle whilst the other is in use. It is one of the slightly more expensive options alongside the Citadel Drill. But it is a purchase that offers you the most convenience and with a half-decent level of care, you will only need to make once in your whole hobby career.

They have a unique wear mechanism that precludes use on metals, which is inaccurate, as wear is more about hardness and thermal effects.

It only supports up to 1.8mm drill bits with one each of 1.0, 1.4 & 1.8 mm bits included in the box. But this means you won’t be able to use this with 3.2mm PCB Drill Bits.

When selecting cutting tool materials, several key properties must be evaluated to ensure efficient and effective cutting performance. These properties play a crucial role in determining the cutting speed, finish quality, and tool lifespan. Understanding these properties helps you choose the most suitable material for your project needs. The main properties of cutting tool materials include hardness, toughness, wear resistance, thermal resistance, and chemical stability.

The Chuck is the part you tighten to grip your drill bits, You can get get a hand drill with a more traditional chuck like you see on normal drills which is entirely variable in size. More commonly, you will see a Hobby drill has reversible Collet(s)

IMHO, this is the perfect Pin Vise. It has a standard build style and is nice and thin. Really sturdy construction and the bearing rotation between the body and handle is firm (no wobbles) and smooth. The body on the D-R is rubberised with a ridged grip making this the most comfortable model available (seriously, check the pics below, the D-R is the exact same vise but it has rubber around it). If you’re drilling a lot of mini’s, this does make a difference. It will likely wear down with time but there’s always the Tamiya Fine Pin Vise D (74050) which is a full metal version.

Aug 30, 2023 — However, when optimized, cutting speed can produce a cleaner, smoother finish. The speed also affects tool wear; overly high speeds without ...

Cutting tool materials are vital for manufacturing and machining operations, consisting of high-speed steels, carbides, ceramics, and diamonds, each engineered for durability and heat resistance. High-speed steels offer toughness and wear resistance, whereas carbides provide superior cutting speeds and longer tool life. Advanced materials like ceramics and diamonds are used for their exceptional hardness and ability to withstand extreme temperatures and abrasive conditions.

Cutting tool materials are pivotal in a wide range of industrial applications. Their selection profoundly impacts productivity, quality, and cost-efficiency in manufacturing processes. Choosing the right cutting tool material depends on factors like the material of the workpiece, desired precision, and machining conditions.

Self-appointed Editor in chief of FauxHammer.com - But I need to thank the team for existing and therefore enabling me to give myself role - without them, I'm just a nerd with a computer and a plastic addiction.

In the medical field, specific cutting tool materials are utilized for manufacturing implants and surgical instruments. These tools require precision, biocompatibility, and minimal wear, factors crucial for producing high-quality, sterile medical components. Diamond and specialized ceramics are commonly used here for their outstanding precision and clean cutting ability.Applications include:

I bought a Tamiya handi drill to use with the PCB bits. I had to wedge the but into the collet, but it works really well. Makes it a lot easier to drill into metal miniatures quickly.

When machining a precision aluminum component for electronics, using a diamond-coated tool can significantly enhance the surface finish and prolong the tool's life compared to conventional tools.

In the automotive industry, cutting tool materials are essential for producing components like engine parts, gear systems, and complex body structures. Tools must endure high speeds and maintain precision across numerous components. Key materials used here include carbides, ceramics, and cubic boron nitride (CBN), each offering different benefits such as wear resistance and thermal stability.

33310 · Bwego · Maisome · Sengerema · Mwanza · 33310 · Ibende · Maisome ... ZIP Code South Africa Postcode Türkiye Posta Kodu. © 2021 – 2024 ...

Understanding the various types of cutting tool materials can greatly aid in selecting the right tool for specific machining processes. With numerous options available, each material comes with its own set of advantages and limitations.

Find out why tungsten carbide is a great choice for drill bits used in oil and gas applications. Learn about its durability, specialized cutting ...

0086-813-8127573

0086-813-8127573