Tungsten Machining & Fabrications - tungsten machining

RPM = SFPM * (3.8197186 / DIA.) ... Every boring job is unique. The cutting tool, the material being cut, the machine the work is being performed on, the nature ...

What is carbon fiber reinforced plasticused for

All times are GMT -4. The time now is 01:17 AM. All CNCzone.com Content - Copyright © 2019 - All Rights Reserved CNC Machines,CAD/CAM,Milling Machines,Lathes,Classifieds, Lasers,Engraving,woodworking,MetalWorking,Industrial Equipment, Manufacturing technolgies

Our extensive line of boring heads and bridge bars gives you right solution for your particular holemaking applications.

Carbon fiber reinforcedpolymer material properties

Carbon fiber is made from a process that is part chemical and part mechanical. It starts by drawing long strands of fibers and then heating them to a very high temperature without allowing contact to oxygen to prevent the fibers from burning. This is when the carbonization takes place, which is when the atoms inside of the fibers vibrate violently, expelling most of the non-carbon atoms. This leaves a fiber composed of long, tightly inter-locked chains of carbon atoms with only a few non-carbon atoms remaining.

Manufacturer of Cold Work Steel offered by Est Tool Steel Pvt Ltd from Mumbai, Maharashtra, India - Hercules Estate, Level No 1, Bank Of Baroda Compound ...

Carbon fiber Reinforcedpolymer price per kg

Tungsten carbide hole saws offer exceptional wear resistance for cutting abrasive materials and ensure a long cutting life. They feature a special tooth ...

Carbon fiber reinforcedpolymer PDF

Drill Bits & Drilling Accessories; Countersink Bits. Countersink Bits. My Wish List. Last Added Items. You have no items in your wish list.

According to an article at energy.gov, carbon fiber composites could reduce passenger car weight by 50%, which would improve fuel efficiency by nearly 35% without compromising the performance of the car or the safety of its passengers.

2019426 — A typical stepover distance for finish V-carving is 0.01" (0.25mm) which works out 2 - 4% depending on the diameter of the cutter.

Shop Norseman Drill 17219 SA-3 Premium Carbide Burr- Cylinder Shape- No End Cut - 1/4" Shank Diameter, 3/4" Cut Length, 3/8" Cut Diameter, Abrasives, ...

What is carbon fiber reinforced plasticmade of

Made tough pumps for non-chlorinated brake parts cleaners. KPV sealing materials and technical plastics. Enclosed end cap pump design.

Carbon Fiber is a polymer and is sometimes known as graphite fiber. It is a very strong material that is also very lightweight. Carbon fiber is five-times stronger than steel and twice as stiff. Though carbon fiber is stronger and stiffer than steel, it is lighter than steel; making it the ideal manufacturing material for many parts. These are just a few reasons why carbon fiber is favored by engineers and designers for manufacturing.

What is carbon fiber reinforced plasticsheet

Dec 20, 2022 — It is less expensive, making it more common and popular. Deformed Steel Bar. Deformed steel bars or rebar are made of hot-rolled steel and ...

In 1963 a new manufacturing process was developed at a British research center, which is where carbon fiber’s strength potential was realized.

What is carbon fiber reinforced plasticvs cfrp

A typical sequences used to form carbon fibers from polyacrylonitrile involves spinning, stabilizing, carbonizing, treating the surface and sizing.

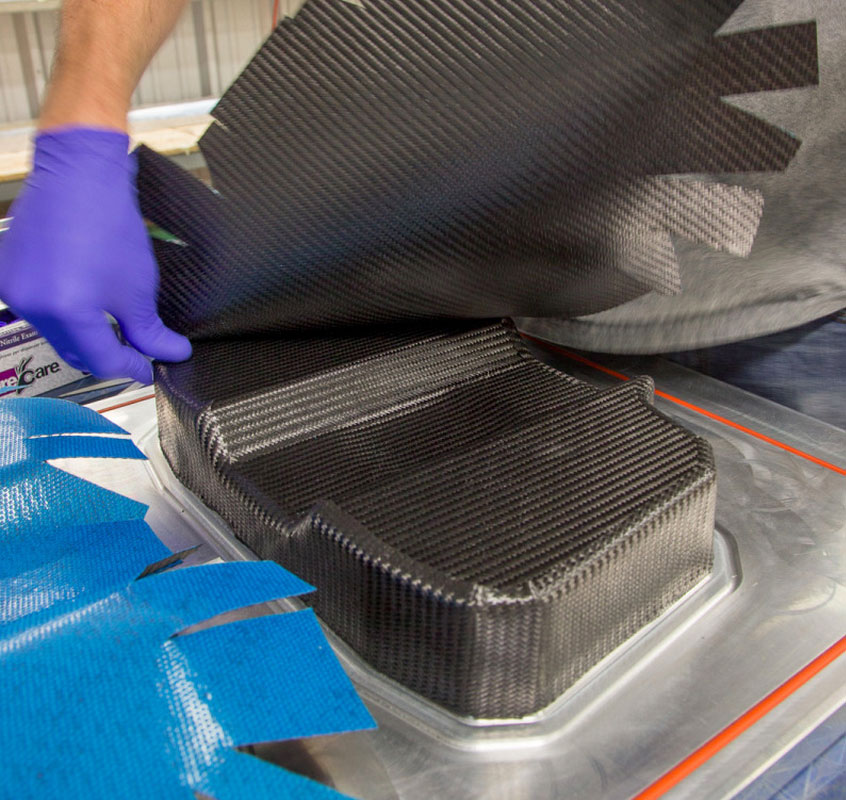

Carbon fiber is made of thin, strong crystalline filaments of carbon that is used to strengthen material. Carbon fiber can be thinner than a strand of human hair and gets its strength when twisted together like yarn. Then it can be woven together to form cloth and if needed to take a permanent shape, carbon fiber can be laid over a mold and coated in resin or plastic.

A popular style of machining steels and hardened steels is high feed milling, these are available in solid or indexable and they designed to run at really high ...

Almost anything. If you would like a carbon fiber pint glass, that can be made. ICE has made many different shapes with carbon fiber and other composites, including:

Because of this, carbon fiber is very popular in many industries such as aerospace, automotive, military, and recreational applications.

Carbon fiber dates back to 1879 when Thomas Edison baked cotton threads or bamboo silvers at high temperatures, which carbonized them into an all-carbon fiber filament. By 1958, high-performance carbon fibers were invented just outside of Cleveland, OH. Although they were inefficient, these fibers contained around 20% carbon and had low strength and stiffness properties.

0086-813-8127573

0086-813-8127573