Tungsten vs Steel - What's Best for a Mens Ring? Answered - tungsten vs steel

Mill finish aluminum is the natural finish of aluminum after it has been extruded and rolled. Depending on the application, it has a dull, matte appearance and can be left as-is or painted. The process of mill finish aluminum is simple and straightforward. It begins with the aluminum being heated to a high temperature and then passing through rollers.

Our DATRON Experts Help Many Customers Bring Manufacturing In-House. Reach Out To Our Team To See Which Machine And Accessories Are The Right Fit For Your Parts.

Mill finish aluminum is more affordable than anodizing, but it is not as durable and does not provide the same level of protection. Although anodizing is more expensive than mill finishing aluminum, it offers a more robust and long-lasting finish. Additionally, anodizing offers a selection of color and texture options that can be used to produce distinctive looks.

Anodizing is a procedure that coats the aluminum with a protective layer. It is an electrolytic procedure that coats the metal with a tough, long-lasting, and corrosion-resistant oxide coating. Anodized aluminum is frequently used in architectural applications because it comes in a variety of colors and can be used to give a building a distinctive appearance.

Mill finish aluminum is a fantastic choice for applications where corrosion resistance is not a big issue. Anodizing is the material of choice for applications where corrosion resistance and durability are crucial.

The most fundamental finish for aluminum is called mill finish, and it is the material’s natural finish. It has exceptional corrosion resistance and is robust and long-lasting. It is an excellent option for things like outdoor furniture, building facades, and maritime applications that need a durable, corrosion-resistant finish.

Metals like aluminum, magnesium, titanium, etc., have found applications in various industries ranging from automotive to aerospace, to electronics, etc., because of their desirable properties.

Corrosion resistance is one of the main advantages of aluminum with a mill finish. The aluminum oxide layer that is formed when the metal is exposed to the air provides a barrier between the aluminum and the environment, preventing rust and corrosion. This makes it ideal for outdoor applications and in areas with high humidity or moisture levels.

The pick and place uses an automated arm to move blanks and finished workpieces from the pallet to the fixture and back. This CNC automation solution is easy to operate, just one program runs both the automation and machining process.

A protective oxide layer is formed on the surface of the aluminum through the more intricate process of anodizing. It can be used to produce a wide range of colors and effects and is more resilient than aluminum with a mill finish. It is crucial to consider the specific application and desired result when deciding between aluminum with a mill finish and aluminum that has been anodized.

Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodizing produces a coating that is extremely durable and resistant to corrosion. Anodizing can give the metal’s surface color, making it harder and more durable. Aluminum and other metals are frequently anodized to prevent corrosion, wear, and abrasion

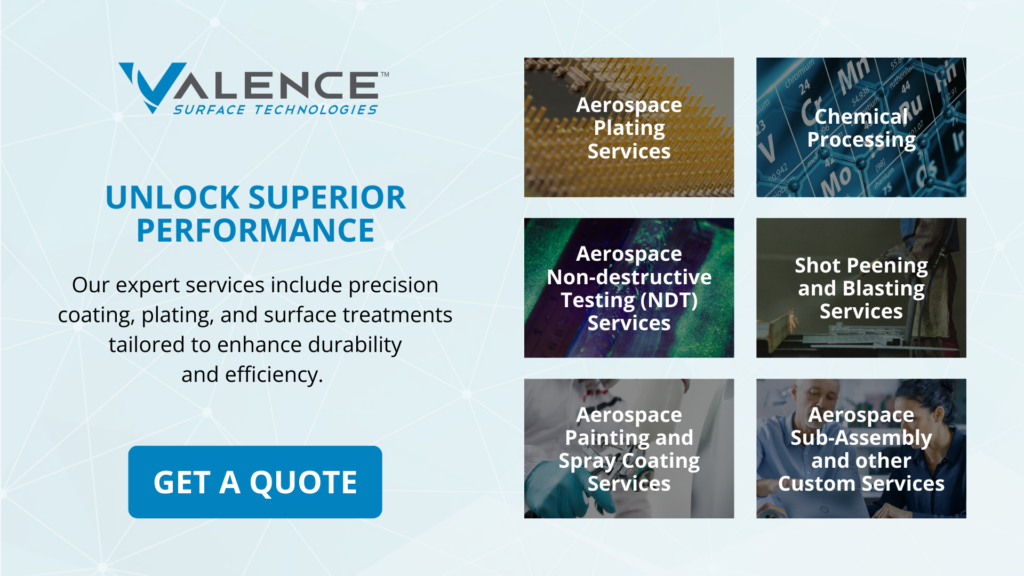

Valence is a full-service surface finishing company specializing in the commercial aerospace, defense, space, and satellite industries. With ten strategically located sites across the United States, Valence provides a start-to-finish solution from NDT and chemical processing to paint and sub-assembly.

Aluminum with a mill finish is also rather lightweight, making it simple to carry and install. This makes it perfect for substantial tasks where the material’s weight must be taken into account.

For aluminum, powder coating is a common finish that is frequently utilized in outdoor applications. It is a long-lasting finish that comes in a range of hues and textures. For outdoor applications, powder coating is a fantastic option because it is UV-resistant and won’t fade or corrode.

Aluminum with a mill finish is produced in an easy and straightforward manner. The process starts with heating the metal to a high temperature before running it through a set of rollers. The aluminum is helped to take on the required shape through this process.

Aluminum that has been extruded from a mill has a natural finish called mill finish. It lacks any protective coating or external surface, making it the most basic type of aluminum. Window and door frames, gutters, siding, and other goods can all be found with an aluminum mill finish. It is a well-liked option for industrial and commercial applications because of its toughness and minimal maintenance requirements.

Lastly, anodized aluminum has better adhesive and primer adherence. This is a result of anodized aluminum’s oxide surface having larger holes than ordinary aluminum. When adhesive, primers, or liquids are applied to the surface, they will flow into the pores, which are essentially holes. Greater adhesion is possible thanks to the anodized aluminum’s ability to absorb liquids.

Many years ago, DATRON AG recognized the importance of reliable workholding and its impact on the machining workflow. That led them to develop a line of workholding solutions for DATRON milling machines. These solutions were designed to be versatile, reliable, accurate, and easy to set up.

The fundamental distinction between mill finish aluminum and anodized aluminum is that anodizing gives aluminum surfaces a protective coating while mill finish metal is unpainted. Aluminum that has a mill finish simply means that it has a natural finish when it leaves the mill.

In observance of Thanksgiving, DATRON Dynamics will be closed on Thursday, November 28th, 2024. We will return to normal operations on Monday, December 2nd.

Anodizing parts is done to increase the durability and corrosion resistance of the aluminum. Anodizing creates a protective oxide layer on the surface of the aluminum, which prevents corrosion and increases the lifespan of the material.

The biggest drawback of mill finish aluminum is that it is unsightly and readily reveals smudges and fingerprints. Also, it is vulnerable to harm from other environmental factors, such as UV light. It is crucial to seal mill finish aluminum with a protective coating, such as paint or anodizing, to prevent corrosion.

Anodizing is a great choice for architectural applications, as it is available in a variety of colors and can be used to create a unique look for a building. Powder coating is a popular choice for outdoor applications, as it is resistant to UV rays and will not fade or corrode.

Aluminum with a mill finish has various limitations that may make it inappropriate for specific applications. The least corrosion-resistant of them is the most important. Because the aluminum’s surface finish is unprotected and exposed to the outdoors, it can corrode quickly when exposed to moisture or other corrosive materials. Moreover, mill finish aluminum is not extremely resistant to dings and other surface blemishes; thus, it might not be appropriate for uses where the metal will be handled or come into touch with people frequently. Last but not least, mill finish aluminum lacks a lot of aesthetic appeal and might not be appropriate for use in ornamental applications.

Millfinishaluminum

This process helps to shape and form the aluminum into its desired shape. The aluminum is then cooled and passed through another set of rollers to flatten it out and make it smooth. Finally, the aluminum is cut to size and packaged for shipment.

Aluminum with a mill finish is strong, long-lasting, and corrosion-resistant, making it perfect for outdoor applications. Also, given its relatively modest weight, it is simple to install and carry. Also, it is reasonably priced, making it a well-liked option for projects with tight budgets.

Millfinishaluminumvs anodized

A benefit of using DATRON’s tested CNC workholding is the time and material you’ll save. How long does it take the operator to load and unload the machine? How much product gets scrapped from slippage? How many tools get damaged and prematurely replaced? These material and time losses translate to dollars lost. Think about how much that totals per part and production run. It could cut significantly into your profit margins. That’s why it’s important to invest in the right workholding.

The compact centric clamp stays completely protected from dirt, chips, and debris. The special slide geometry with a guide length of 150 mm makes it a fully encapsulated centric clamp.

Need to stay flexible and keep cycle times down? Then pneumatic clamps (short stroke and positional) are a smart, time-saving workholding to use.

Aluminum is rolled and extruded into the desired form to get mill finish. The aluminum is heated to its melting point during this procedure, which is typically between 600 and 650 degrees Celsius. The desired shape is then imparted to the molten aluminum by forcing it through a die. After cooling, the aluminum is cut to the required length.

When choosing the best finish for aluminum, consider the environment it will be exposed to, the aesthetic you are trying to achieve, and the intended use of the aluminum. Mill finish aluminum is a great choice for applications that require a strong, corrosion-resistant finish.

Anodizing is a process that changes the surface of aluminum to create a protective layer. It is done by submerging the aluminum in an acid solution and passing an electric current through it. This causes a reaction that forms a layer of oxide on the surface of the aluminum. This layer acts as a barrier to corrosion and other elements, making it more durable and resistant to wear and tear. Anodizing can also be used to change the color of the aluminum, allowing for a wide range of colors and finishes.

One of the key benefits of aluminum with a mill finish is its resistance to corrosion. Rust and corrosion are prevented by the aluminum oxide layer that forms when the metal is exposed to air. This layer serves as a barrier between the aluminum and the outside world. This makes it perfect for outdoor applications and places with a lot of moisture or humidity.

Aluminum millprice

This is where the DATRON magic happens. No gaskets are needed with this design, just a layer of card stock. The vacuum table efficiently secures workpieces to the milling machine bed. Even thin stock, like plastic foil as thin as 0.001″ and delicate, soft materials, can be secured within seconds.

However, these applications require that these metals are deployed in harsh service conditions. These conditions include high humidity, high temperature, the presence of acids and salts in a service environment etc., causing these metals to lose their properties or parts. The result of this is the failure of these metals in service, resulting in a high cost of maintenance or component replacements.

It has no protective coating and has not been treated in any way. On the other hand, anodizing is an electrochemical procedure that gives aluminum surfaces a protective coating. By incorporating color, texture, and other elements, anodizing also enhances the appearance of metal.

Aluminumrollingmill

Anodized aluminum has greater lubrication than ordinary aluminum, but its greatest advantage is undoubtedly its superior resistance to resistance. When aluminum is anodized, the metal’s pores are made deeper, which enhances the metal’s capacity to retain lubricating oil or film. Standard aluminum has a smooth surface, so it’s unable to retain lubricating oil or film.

How can dyeing be supported on anodized aluminum? Aluminum is exposed to substances that are acidic during the anodizing process, such as sulfuric acid, which causes a thicker oxide layer and a porous surface to form. Anodized aluminum’s porous surface makes it better able to take dye than ordinary aluminum’s smooth, nonporous surface.

The anodizing process involves submerging the metal parts into an electrolyte solution, such as sulfuric acid or chromic acid, and then passing an electrical current through the solution. A thin oxide layer forms on the metal’s surface as a result of a reaction between the metal and the electrolyte brought on by the electrical current.

Yes, mill finish aluminum can corrode over time. This is because it has not been treated with a protective coating or finish, and so is more exposed to the elements. To prevent corrosion, it is recommended to use a protective coating such as anodizing or painting.

T-Slot table CNC workholding mounts to the machine bed and can be equipped with wedge clamping or short stoke pneumatic clamps among other solutions.

In observance of Christmas, DATRON Dynamics will be closed on Tuesday, December 24th, 2024. We will return to normal operations on Thursday, December 26th.

The wedge clamping CNC workholding units can be configured for single and multiple clamping setups. The clamps can be used flexibly on the DATRON T-slot plage thanks to the clamping screw and T-nut.

Aluminum millnear me

From prototype to production, DATRON Dynamics optimizes your entire machine workflow with touchscreen-enabled DATRON CNC machines. With headquarters located on the East Coast in Milford, New Hampshire, and an office in Livermore, California, we are your one-stop DATRON Partner in North America

Aluminum with a mill finish is a fantastic material for many purposes. This flexible material is frequently employed in both industrial and commercial settings. It is sturdy, manageable, and reasonably affordable. Furthermore, it offers a low-maintenance surface that doesn’t need any additional treatments or coatings.

When it comes to finishing aluminum, there are two main options: mill finish aluminum and anodizing. Both of these processes are designed to improve the look and longevity of aluminum, but they have different advantages and disadvantages. Mill finish aluminum is aluminum’s natural, unfinished look, while anodizing is an electrochemical process that creates a hard, protective layer.

Anodizing and mill finishing are two common methods for completing aluminum products. When an aluminum product is first manufactured, it is finished with a mill finish. It is a straightforward procedure that results in a matte finish with no additional corrosion protection.

A mill finish on aluminum makes it a terrific material for a variety of uses. Both industrial and commercial applications regularly use this flexible material. It is strong, controllable, and fairly priced. It also provides a surface that requires little upkeep and doesn’t require any further coats or treatments.

When it comes to choosing the best finish for aluminum, there are a few factors to consider. The aluminum’s intended function, the conditions it will be exposed to, and the aesthetic you want to create will all influence the treatment you choose.

In conclusion, the main distinction between mill finish aluminum and anodizing is that the former is unfinished, whereas the latter is an electrochemical process that gives aluminum surfaces a protective coating. Aluminum with a mill finish is more economical but less tough, whereas aluminum with anodizing is more expensive but has a tougher, longer-lasting finish.

Our work pallets or QuickPallets are one of our CNC workholding solutions that are keyed using a beveled boss-in-cavity system to ensure location repeatability.

Anodizing can also be used to color the surface of the metal. This is done by adding dyes or pigments to the electrolyte solution. The dye or pigment is embedded in the oxide layer covering the metal’s surface as a result of the electrical current. This can be used to produce a variety of colors, ranging from muted tones to vivid hues.

VulcanAluminum Mill

You can use a protective coating such as anodizing or painting to protect a mill finish of aluminum. Anodizing is a process that involves electrolytic passivation, which creates a protective oxide layer on the surface of the aluminum. Painting is another option, as it provides a barrier between the aluminum and the elements.

In order to create colored aluminum items, anodized aluminum can also be colored. Dyeing is often not supported on standard aluminum. Companies who employ ordinary aluminum are therefore limited to using it in its natural chrome color. Luckily, anodized aluminum can quickly and effectively address this issue. Anodized metal may be colored to any hue or mix of colors, unlike regular aluminum.

Aluminum and other metals are frequently anodized to prevent corrosion, wear, and abrasion. Besides improving the metal’s aesthetic appeal, it is also utilized to make it harder and more durable. Anodizing is a reasonably cheap procedure that may be used to create a variety of colors and finishes with good corrosion and wear resistance.

Knowing the differences between mill finish aluminum and anodizing can help you decide which is the best finish for your aluminum project. In this article, we’ll explore the pros and cons of both mill finish aluminum and anodizing and the key differences between them. We’ll also discuss how to protect mill finish aluminum and answer some frequently asked questions.

Aluminummills USA

Aluminum that has been anodized is more corrosion-resistant than plain aluminum. Both regular and anodized metal cannot rust. Yet, they still have the potential to corrode when exposed to moisture, air, salt, or other substances or elements that prevent corrosion. Yet, because anodized aluminum has a thicker layer of oxide than ordinary aluminum, it is less likely to corrode.

Each workholding solution was designed to significantly reduce your setup times, help ensure positional repeatability, and improve your production quality overall. DATRON takes it beyond optimized workholding though, since the engineers designed the entire workflow to be more efficient and easy. At DATRON Dynamics, we are your one-stop shop for DATRON CNC mills, workholding accessories, carbide cutters, training, and application support. Curious how a DATRON could improve your manufacturing process? Just ask us.

You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as rigid and vibration-free as possible) then all that means nothing. “A horse, a horse! My kingdom for a horse!” This quote is understood by every machinist, tool and die maker, production cell supervisor, and operations manager. Nothing stops a successful process in its tracks like poorly secured material, which can cause tool breakage, material slip, high scrap rates, possible machine damage, and worst case scenario, potential operator injury. So, let’s take a closer look at some CNC workholding options.

Aluminumrolling mills in USA

After cooling, the aluminum is sent through a second set of rollers to flatten and smooth it out. The aluminum is then packaged for shipping after being trimmed to size.

The rotary swivel table, aka the trunnion, mounts in the cut-out of a DATRON’s machine bed. This upgrades the 3-axis milling machine to 5th-axis capabilities.

Anodizing uses an electrolytic process that involves submerging the aluminum in an acid bath. This bath contains sulfuric acid, chromic acid, and oxalic acid, which are used to create the protective oxide layer on the surface of the aluminum.

Anodizing and mill finish aluminum are two distinct procedures used to protect and enhance the appearance of metal. A protective coating is applied to aluminum surfaces through the electrochemical process of anodizing, whereas mill finish aluminum is a basic, unfinished product.

This layer is extremely resistant to corrosion, wear, and abrasion and is typically between 0.0002 and 0.003 inches thick.

Please contact us with any questions about our aluminum finishing process or request a quote today. With that being said, let us delve right into business without further delay.

0086-813-8127573

0086-813-8127573