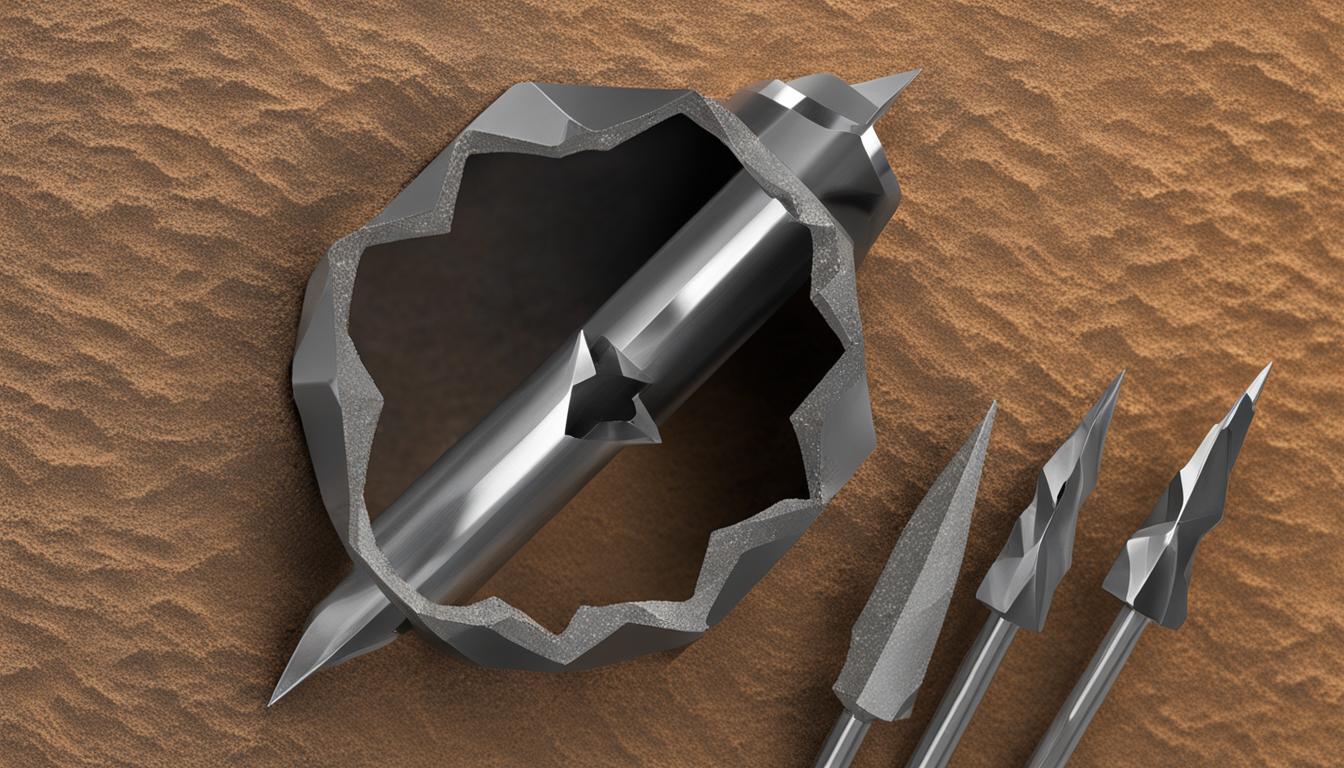

Types of Milling Tools 101: Precision Crafting Essentials - mill bit types

Using high-quality diamond drill bits for stucco walls can save you time and effort in the long run. These durable drill bits can withstand the demands of drilling through stucco and are less likely to break or become dull compared to other types of drill bits. With their long lifespan, you can complete multiple stucco projects without constantly replacing your drill bits.

Additionally, it’s paramount to analyse the water level before drilling commences, as water can affect the drilling process, mainly when dealing with porous layers. This method is also perfect for narrow-space sites, as the equipment is compact and can be easily manoeuvred in confined environments.

Percussive drilling allows workers to reach deeper strata efficiently in industries such as oil and gas, mining, and geothermal energy.

Drilling typerig

Additionally, inspect welding on all tools regularly and replace or purchase new ones if they aren’t working in their best condition.

This method suits tasks requiring deep, precise drilling in tough materials, making it a prominent choice in Surrey construction and industrial projects. The drill’s power comes from the force applied, delivering rapid, successive blows that shatter the material at the drill face.

As you can see, both diamond and carbide drill bits have their own strengths and can be effective for drilling into stucco. Consider the specific needs of your project and choose the drill bit that aligns with your requirements. With the right drill bit in hand, you’ll be able to tackle your stucco drilling projects with confidence.

These top-rated drill bits have received high praise from professionals and DIY enthusiasts alike, making them reliable choices for your stucco projects. They are designed to handle the tough nature of stucco, providing clean and precise holes every time.

When using a diamond drill bit, it is important to note that a slow drilling speed is recommended to prevent the bit from overheating and prolong its lifespan.

Depending on the project requirements, the drill bit can be outfitted with different materials, such as diamonds, to increase cutting efficiency, especially in more rigid rock formations.

However, when dealing with grounds that have high gravel levels, rotary drilling may face challenges, as the gravels tend to rotate beneath the drill bit without being effectively broken up, reducing efficiency.

On the other hand, hammer drill bits are designed for use with hammer drills, which provide additional power and impact for drilling through tough materials like stucco. The hammer drill bit features a unique design with flutes and a reinforced carbide tip that can withstand the pounding action of the hammer drill. This type of drill bit is versatile and can handle a variety of materials, making it a good choice for stucco projects where you may encounter different materials during your drilling.

Contemporary hydraulic drilling rigs are equipped with computer operating systems that enhance precision and operational control. These systems also enable drilling larger-diameter boreholes, which are essential for extensive-scale projects like water wells, oil exploration, and geothermal drilling.

Rotary air blast drilling is chiefly used for mineral exploration, providing deep and straight holes with reduced energy loss.

Rotary drilling Surrey operates by rotating a drill bit continuously into the ground, cutting or grinding the material as it goes deeper. The process relies on the rotation of the bit combined with downward pressure to penetrate the surface.

This type is ideal for drilling into hard rock formations. The drill bit rotates, crushing and breaking the rock as it moves downward. This type of drill is extensively used in large-scale drilling projects, including oil, gas, and water well drilling, as it can penetrate deeply into earth layers.

When it comes to construction and drilling projects in Surrey, choosing the ideal technique makes a significant difference in efficiency and results. Several options are available in the market, making selection complicated for businesses and project managers.

Additionally, it’s known for its inch-perfect results, allowing for clean, controlled drilling that minimises damage to surrounding structures. This precision is paramount in preserving the integrity of the work site while achieving the intended depth and width.

If you require extra power when drilling into tough materials like stucco, a hammer drill bit is an invaluable tool. Designed for use with hammer drills, these bits deliver additional impact force to break through stucco with ease. Hammer drill bits are versatile and effective, making them a preferred choice for professionals and ambitious DIY enthusiasts.

Additionally, this technique is pivotal for large-scale operations where both speed and depth are critical factors. Its importance lies not only in its ability to handle rigid materials but also in its role in maximising productivity and keeping project timelines in check.

Carbide drill bits are another popular option for drilling into stucco. They are made with a carbide tip that is highly resistant to wear and can handle tough materials like stucco. Carbide drill bits are known for their durability and can provide reliable performance when drilling into stucco. They are particularly useful for smaller drilling tasks or when working on projects that require precision.

This type uses dual-walled drill pipes to carry the drill cuttings back to the surface through the inner pipe, keeping the borehole clean and debris-free. It is highly efficient for deeper holes and is often used in mineral exploration, water wells, and environmental drilling, as it provides accurate samples from depth.

Not only do diamond drill bits offer superior performance, but they also create clean and precise holes in stucco walls. This is crucial, especially if you’re working on a project that requires accurate placement or if aesthetics are important to you. The clean holes created by diamond drill bits make it easier to insert screws or anchors securely, ensuring a sturdy installation.

With their diamond-tipped cutting edges, these drill bits provide excellent strength and resistance to wear, ensuring that they can handle the tough stucco material without losing their sharpness. The diamond coating helps to improve drilling speed and efficiency, allowing you to complete your stucco projects more effectively.

Standard Drill Sizes - Inches ; Drill. Size . Decimal. Equiv. ; 80, = .0135 ; 79, = .0145 ; 1/64, = .0156 ; 78, = .016 ...

With these top picks, you can trust that you’re investing in drill bits that are known for their quality and performance. So, whether you’re a seasoned contractor or a weekend warrior, these drill bits will help you tackle any stucco project with confidence.

When it comes to drilling into stucco, having the right drill bit is crucial for achieving clean and precise holes. In this article, I will share my top picks for the best drill bits for stucco and provide some expert tips to help you drill confidently. Whether you’re a DIY enthusiast or a professional contractor, these drill bits will make your stucco projects a breeze.

When deciding between masonry drill bits and hammer drill bits for drilling into stucco, consider the specific needs of your project and the tools you have available. If you are primarily working with stucco and want a dedicated drill bit for the job, a masonry drill bit is an excellent choice. It provides precision and durability for drilling into stucco materials. On the other hand, if you work with a variety of materials and have a hammer drill at your disposal, a hammer drill bit can provide the versatility and power you need to handle different surfaces.

When choosing between diamond and carbide drill bits for stucco, consider the specific needs of your project. If you are working on larger holes or need maximum durability, diamond drill bits are an excellent choice. On the other hand, if you’re focusing on precision or smaller drilling tasks, carbide drill bits can provide reliable results. Ultimately, your decision should be based on the requirements of your stucco drilling project.

Percussion drilling Surrey is also the perfect choice for drilling in firm soils, especially those containing layers of rubble or stones, where other techniques may struggle. In research applications, it is highly suitable for projects involving soil pollution studies, grain size distribution, general soil classification, and profile description.

Types ofdrillingmethods PDF

When it comes to drilling into stucco, choosing the right drill bit is crucial for achieving clean and precise holes. Two popular options for drilling into stucco are diamond drill bits and carbide drill bits. Both types of drill bits have their own advantages and are suited for different stucco drilling projects.

By considering the type of stucco, the size of the holes, and the material of the drill bit, you can select the best drill bit for your stucco project. Choosing the right drill bit will ensure clean and precise drilling without damaging the stucco.

When it comes to choosing between percussive and rotary drilling, both techniques offer distinct advantages, and the “best” choice ultimately depends on the project’s specific requirements.

Percussive drilling Surrey involves quick, repeated hammer-like blows to the drill bit, forcing it into the material and breaking it to pieces. Each impact chips away at the surface, allowing the drill to penetrate even the most rigid materials, such as rock or reinforced concrete.

Up & down cut milling. When choosing a method to machine, up cutting or down cut milling (climb milling) is decided by the conditions of the machine tool, the ...

Both masonry and hammer drill bits are suitable for drilling into stucco. The choice depends on your tools and specific needs.

Percussive drilling is generally used in construction projects with dense foundations or mining operations requiring deep penetration into formidable rocks. In such conditions, it excels at providing both toughness and precision.

These two are highly used methods, each suited to specific conditions and materials. This blog will guide you through both techniques, explaining how each works and where they are most effective.

Steeldrilling type

When it comes to drilling into stucco, choosing the right drill bit is essential for achieving clean and precise holes. Two types of drill bits commonly used for stucco are masonry drill bits and hammer drill bits. Let’s explore the differences and considerations for each.

Machine Shop. BBB Rating: A. not BBB accredited. (256) 519-2353. 3100 Soap Cir ... R & R Speed Shop, Inc. Car Racing Equipment, Machine Shop, Auto Machine Shops.

Percussive drilling Surrey plays an integral role in construction and mining, where drilling through dense, demanding materials is necessary. Its ability to deliver high-impact forces makes it a valuable technique to drill through challenging surfaces that might otherwise resist traditional methods.

In construction, oil and gas, and mining industries, rotary drilling empowers you to reach significant depths while maintaining drilling precision.

If you’re searching for durability and versatility, look no further than carbide drill bits for stucco. These tough bits can handle tough materials like stucco and are suitable for both DIY enthusiasts and professionals. Carbide drill bits are capable of producing clean and precise holes in stucco, ensuring your projects turn out flawlessly.

Types ofdrillingin oil and gas

All these valuable insights into both techniques will help you make informed decisions about which one to choose for your project needs. Whether it’s for construction, mining, or exploration, these two techniques provide the flexibility and potency required to get the job done efficiently.

Purchase quality drill bits, counter sink online at Chamberlain Timber Mart in Gravenhurst-Muskoka Ontario.

So, if you’re looking for the best drill bit for stucco walls, I highly recommend investing in a high-quality diamond drill bit. With its exceptional performance, durability, and ability to create clean and precise holes, a diamond drill bit will make your stucco projects more efficient and successful.

Pay attention to your tool’s LED service lights and strictly follow maintenance guidelines when any red flags appear. Adhering to these practices ensures that your rotary drilling equipment performs efficiently and lasts longer.

Whether you’re in construction, mining, or industrial work, understanding these two techniques is essential for making informed decisions. Let’s get started to help you determine which one is best for your project.

Furthermore, the material of the drill bit is crucial for stucco projects. There are different drill bit materials available, such as diamond, carbide, and masonry. Diamond drill bits are ideal for stucco walls due to their ability to cut through hard materials like concrete and stone. Carbide drill bits are also effective for stucco and offer excellent durability. Masonry drill bits are specifically designed for drilling into masonry materials, including stucco.

Rotary drilling is also considered eco-friendly due to its minimal vibrations, noise, and dust production. It makes it a more sustainable solution in environments where lowering environmental impact is a top priority.

In addition, consider the size of the holes you need to drill. Whether you’re installing screws or creating openings for wiring, ensure that the drill bit is compatible with the size requirements. This will prevent any issues or damage during the drilling process.

Percussive drilling Surrey is ideal for rigid, dense materials and is highly effective at cutting through complex formations. It is perfect for mining and construction projects in challenging environments. Its simplicity, precision, and ability to deal with diverse rocks make it a reliable choice for drilling on hard ground.

When choosing a drill bit for stucco walls, consider the type of stucco, the size of the holes, and the compatibility with your drill.

The masonry drill bit is recommended for drilling holes for stucco screws, as it provides excellent performance and durability.

Rotary drilling often uses wire-line core barrels with diamond drill bits to efficiently penetrate the most demanding rock formations.

Rotary drilling Surrey is highly versatile and is employed across multiple industries, especially for quick drilling that allows core recovery at massive depths. This technique is best suited for geological exploration, mining, and oil extraction, where deep, precise drilling is required.

Additionally, it is used in geothermal energy projects, where deep drilling into the earth’s crust is necessary to access heat sources.

This type employs a helical screw to bring the cuttings to the surface. It is primarily used for drilling shallow holes in soft soils and unconsolidated materials. Auger drilling is standard in environmental and geotechnical research due to its simplicity and efficiency in soft ground conditions.

The drill bit rotates continuously, grinding the material at the point of contact, making it highly efficient for creating large, deep holes. This method is highly preferred in the oil and gas industry, as well as for water well drilling, geothermal energy projects, and foundation work.

Microcut is a manufacturer of Premium Quality Carbide End Mills and Special Application Rotary Cutting Tools for industrial and medical applications.

Using a masonry drill bit for stucco screws not only ensures clean and precise holes but also helps prevent any damage to the stucco. The sharp cutting edges reduce the risk of cracking or chipping the stucco, minimizing any potential repairs or touch-ups.

The flexibility provided by its advanced technology, including hydraulic rigs and computer operating systems, makes it a go-to method for oil and gas exploration and geothermal projects.

Additionally, rotary drilling provides excellent penetration rates across different lithologies, ensuring exceptional operational efficiency irrespective of ground conditions.

As the cut nail is driven deeper, it displaces the concrete around the shaft. This displacement creates a compressed zone of material that ...

Keep in mind that using a hammer drill bit may cause some roughness on the surface of the stucco, but this can be easily smoothed out during the finishing stage.

This technique does not rely on continuous rotation but uses a striking motion, making it suitable for situations where high impact is needed.

Types ofdrillingin mining

Rather than favouring one, the decision should be based on the specific drilling conditions and project goals. Both methods offer unique benefits, ensuring the appropriate solution is available for various drilling needs.

Furthermore, this drilling technique excels in situations where both depth and precision are required, such as in geological investigations, oil exploration, and water well drilling.

If you face the same dilemma and want to make informed decisions, you have come to the right place. We will discuss two primary drilling techniques in Surrey: percussion and rotary drilling.

It’s paramount to let the tool function without applying excessive pressure, as pressing too hard can cause unnecessary wear. Consider the material you’re drilling and the hammer size before selecting the appropriate drill bit for maximum efficiency.

Sep 27, 2023 — Various types of milling operations cater to diverse machining needs. Face milling creates flat surfaces, while end milling produces slots and ...

Our competent team understands every client’s-specific project requirement. Accordingly, they formulate tailored solutions and suggest the most suitable drilling technique for your project needs.

This technique is prominent in mining and geological exploration, where highly accurate samples are required from deep rock layers.

The different types of drill bits for stucco include diamond drill bits, carbide drill bits, masonry drill bits, and hammer drill bits.

Remember, using the correct drill bit for stucco will not only ensure a successful drilling process but also help you achieve professional-looking results without damaging the material.

Masonry drill bits are specifically designed for drilling into masonry materials, including stucco. These drill bits provide excellent performance and durability, allowing you to easily drill holes for your stucco screws. They have a sharp cutting edge that can penetrate the stucco smoothly, resulting in clean and precise holes.

This technique is excellent for drilling through softer to medium-hard materials and allows for the creation of large-diameter holes. In oil drilling or geothermal energy applications, rotary drilling Surrey can reach far below the earth’s stratum with utmost precision.

After reading the blog, you will have obtained excellent clarity about percussive and rotary drilling techniques. You will have comprehended their respective importance, how they work, the maintenance involved, types, preferable conditions, advantages, and applications.

Percussive drilling, also known as hammer drilling, is an extensively used technique where the drill bit repeatedly strikes the material, breaking it apart with each impact.

In the realm of stucco drilling, diamond drill bits reign supreme. These drill bits are specifically designed to tackle hard materials such as concrete and stone, making them an excellent choice for drilling into stucco walls. The diamond tip ensures clean and precise holes, making it ideal for professional contractors or those seeking exceptional results.

In mining, percussive drilling is essential for reaching deep into the earth’s subsurface to extract valuable minerals. Its ability to drill through diverse rocks and ground layers, including above and below the water table, makes it a preferred choice for many mining operations.

In this section, we will discuss the four primary types of rotary drilling, each tailored to specific ground conditions and project needs. Let’s dive into the four types used in various industries:

Diamond drill bits are specifically designed for drilling through hard materials like concrete, stone, and stucco. They are made with a diamond-tipped cutting edge that is extremely durable and can withstand the abrasive nature of stucco surfaces. Diamond drill bits provide excellent performance and durability, making them an ideal choice for drilling into stucco. They are especially effective when drilling larger holes or working on more extensive stucco projects.

Regular inspection of the drill bit for wear and tear is pivotal, as worn bits can lead to diminishing performance and increased downtime. To maintain cutting efficiency, it’s vital to sharpen the teeth of the drilling bit at regular intervals using an angle grinder.

So, whether you’re a DIY enthusiast or a professional contractor, remember to invest in high-quality drill bits that are suited for stucco projects. By following the expert tips and using the recommended drill bits, you can achieve clean, precise, and professional results every time. Happy drilling!

Drilling typepdf

The masonry drill bit’s high-quality construction ensures that it can withstand the tough demands of drilling through stucco. It is made from hardened steel, making it strong and durable. This durability allows the drill bit to maintain its sharpness even after prolonged use, ensuring consistent performance and long-lasting use.

Drilling into stucco requires some specific techniques to ensure successful results. Here are some tips to follow when drilling into stucco:

When it comes to drilling into stucco, having the right drill bit is crucial for achieving clean and precise holes. That’s why I’ve compiled a list of the best drill bits for stucco, based on their performance, durability, and ability to handle stucco materials.

by MR Khan · 2010 · Cited by 4 — transient dynamic load conditions during the machining process to verify its design. Keywords: custom-engineered form milling cutter, finite element analysis.

Masonry drill bits are specifically designed for drilling into masonry materials, including stucco. These drill bits offer excellent performance and durability when it comes to working with tough materials like stucco. They have a sturdy construction with a tungsten carbide tip that ensures efficient drilling. The masonry drill bit is ideal for projects that require accurate and clean holes in stucco surfaces.

In this type, a drill hammer at the top of the drill string transmits the impact energy through the rods to the drill bit. This technique is perfect for shallow to medium-depth drilling in hard materials like rock. It is extensively used in mining and construction projects that require precision and durability.

Unlike rotary drilling, which relies on rotational motion, percussive drilling uses quick hammering to penetrate rigid surfaces, such as concrete slabs or natural rocks.

Keeping tools clean at the end of each day will also extend their lifespan. Cords, in particular, will last longer if all mud is cleaned and hung up to dry. By maintaining the equipment regularly, you ensure optimal performance, lower operational costs, and extend the lifespan of the drill.

When it comes to drilling holes for stucco screws, it’s important to use a drill bit that can create clean and precise holes without causing any damage to the stucco. With the right drill bit, you can ensure that your stucco screws are securely and safely installed. One of the best drill bits for stucco screws is the masonry drill bit.

Also, if you want to leverage the strengths of each method, CA Drillers is your ultimate solution. We have extensive experience in providing drilling services across Surrey and London.

Some top-rated drill bits for stucco include BOSCH Hammer Drill Bits, COMOWARE Hammer Drill Bits, and DEWALT Hammer Drill Bits.

For optimal performance, it’s vital to use the correct size and a slow drilling speed when working with masonry drill bits.

This type involves using a hollow, cylindrical drill bit that collects the core as it cuts into the material. It is highly suitable for drilling through softer rock formations and provides relatively clean samples. It is often used in geological exploration, where core samples are required for analysis.

To conquer stucco projects, masonry drill bits are excellent options. Specifically designed for drilling into masonry materials, including stucco, these bits are durable and efficient. Masonry drill bits provide the strength needed to effortlessly penetrate stucco surfaces while retaining precision.

In contrast, rotary drilling Surrey excels in softer materials and can reach significant depths with exceptional efficiency, especially in projects where speed and borehole size are critical.

Rotary drilling is versatile and can be used in both hard and soft lithology (study of rocks), making it suitable for diverse ground conditions. Initially developed to examine rocks, rotary drilling Surrey is also used in soil applications.

Other essential maintenance tasks include checking that the bailer valve is functioning appropriately for smooth operation and replacing the rope around the rope eye if it shows signs of damage.

Each type offers unique benefits, allowing for flexibility across a range of drilling conditions and project requirements.

In this type, the drill hammer is positioned at the bottom of the hole, just behind the drill bit. The compressed air drives the hammer, enabling efficient drilling in rigid rock formations.

Firstly, it’s crucial to assess the type of stucco you’ll be drilling into. Stucco walls can vary, from thin “California 3 coat” stucco to thicker layers. The thickness of the stucco will impact the type of drill bit you should choose.

However, rotary drilling may not always be ideal for projects requiring detailed sampling. This technique can present challenges when recording earth strata, making it less suitable for those needing highly accurate soil or rock samples.

Now let’s take a look at a comparison table of the key features and benefits of diamond and carbide drill bits for stucco:

By considering the type of stucco, the size of the holes, and the material of the drill bit, you can choose the best drill bit for your stucco projects. Diamond drill bits are perfect for drilling through hard materials like stucco, while masonry drill bits are specifically designed for drilling into masonry materials. If you require extra power, hammer drill bits are a great choice for stucco. It’s important to select the right size and type of drill bit to ensure the best results.

Rotary drilling is highly potent in softer soil conditions, allowing for the extraction of samples and creating deep, clean boreholes. It is highly beneficial for projects requiring large-diameter holes or penetrating through various soil layers and rock formations.

Diamond drilling Surrey uses a diamond-embedded bit to cut through highly rigid materials. It is known for its precision and ability to produce clean, precise core samples.

Regular cleaning of the drill bit is also crucial. Wipe off any dirt at the end of each operation to prevent it from entering the hammer, which could result in tool failure. Grease the drill bit each time it is changed to prevent untimely wear of the bit holder, and always use the manufacturer-recommended grease.

This versatile drilling technique can handle diverse ground conditions, from softer soils to dense rock formations. It is well-suited to different types of rocks, allowing for greater flexibility in its application.

Drilling typeand sizes

One prominent benefit is the lightweight and modular design of the rigs, which allows for outstanding flexibility and straightforward installation on-site. Rotary drilling Surrey is quicker than many conventional drilling techniques, delivering high-integrity results with top-notch efficiency.

When it comes to drilling into stucco walls, I’ve found that using the right drill bit is essential for creating clean and precise holes. One of the best options for drilling into stucco walls is the diamond drill bit. Designed specifically for drilling through hard materials like concrete and stucco, diamond drill bits offer exceptional performance and durability.

To summarize, when drilling into stucco, consider the specific needs of your project and choose the drill bit that best suits them. Whether it’s diamond for exceptional performance, carbide for durability, masonry for precise drilling, or hammer for added power, each type of drill bit has its own strengths to ensure successful stucco drilling ventures.

When it comes to selecting a drill bit for stucco, it’s essential to consider several factors to ensure successful drilling. By taking into account the type of stucco, the size of the holes, and the material of the drill bit, you can choose the perfect tool for your stucco project.

Depending on the lithology of the drilling site, each variation of rotary drilling offers distinctive advantages, making it a versatile and dependable choice for diverse drilling needs.

Additionally, percussive drilling can reach impressive depths, drilling hundreds of feet into the ground while maintaining precision. Its ability to drill through above and below the water table makes it highly valuable for projects requiring extensive penetration, such as mining, construction, and geothermal applications.

Rotary drilling Surrey is crucial for projects requiring drilling through several types of soil and rock formations. It offers the flexibility to adjust drilling speed and pressure according to the ground conditions, ensuring efficiency across various drilling environments.

Types ofdrillingmachine in workshop

Each type of percussive drilling offers distinct advantages depending on your project’s specific needs, ensuring that the most suitable method is available for any drilling challenge.

Percussive drilling is broadly used across various industries because it can handle harsh ground conditions and drill through complex formations. In the construction industry, it is generally used for foundation drilling, where it can penetrate dense materials such as rock and concrete. It makes it perfect for building foundations, tunnel construction, and other large infrastructure projects where precision and depth are top priority.

Maintaining rotary drilling equipment is vital for ensuring optimal performance and extending the tool’s lifespan, especially when working with challenging materials like concrete.

Rotary drilling offers several incredible advantages, making it a preferred technique in several industries, from construction to mining.

Choosing the right drill bit for stucco is crucial for achieving clean and precise holes without damaging the material. With the top picks and expert tips provided in this article, you can confidently tackle any stucco project. Whether you need to drill into stucco walls or install stucco screws, there are drill bits available that are specifically designed for these tasks.

Some tips for drilling into stucco include using a drill with variable speed, starting with a small pilot hole, and using a masonry drill bit appropriate for the hole size.

To further enhance the performance of your masonry drill bit and ensure optimal results, it’s essential to use it with the correct drilling technique. Apply steady and even pressure while drilling, and remember to start with a small pilot hole to guide the larger drill bit. These techniques, combined with the use of a high-quality masonry drill bit, will help you achieve professional-looking results.

2023629 — Gold (0.004 ppm) is the rarest precious metal, followed by platinum (0.005 ppm) and silver (0.075 ppm). By comparison, aluminum, the most common ...

To choose the right drill bit for stucco projects, consider the type of stucco, the size of the holes, and the material of the drill bit.

Despite this, rotary drilling Surrey remains an outstanding choice for quickly and efficiently drilling large-diameter boreholes in projects where depth and speed are critical.

1. US Wavy Flag - 3D STL Model for CNC - length: 19.68 inches (500 mm) - width: 10.4 inches (264 mm) - thickness: 1.1 inches (28 mm)

Percussive drilling’s efficiency lies in its ability to concentrate force at the point of contact, enabling deep, precise holes in demanding materials with minimal wear on the surrounding structure.

Rotary drilling is a broadly used technique in which a rotating drill bit is employed to cut through materials. This technique is highly suitable for softer earth materials and potent in drilling in-depth into more complex surfaces.

By following these simple tips and using the best drill bit for stucco screws, you can confidently install stucco screws without worrying about damaging the stucco or compromising the integrity of your project.

So, get the correct guidance and hassle-free consultation from our experts to resolve your doubts and discuss your project requirements. Contact us at 08082747824 or info@cadrillers.com.

One vital benefit is its ability to remove boulders and cut through complex formations quickly and effectively, making it suitable for drilling through major earth layers. It is a straightforward method to operate and maintain, making it accessible for a range of projects and drilling environments.

Percussive drilling Surrey is highly effective for drilling into demanding materials, including hard rock, concrete slabs, and dense soil. It is particularly suitable for layers such as sand, silt, stiff clays, sandstone, laterite, and gravel, where conventional rotary drilling might struggle. The hammering action of percussive drilling enables it to penetrate these materials with precision and efficiency.

When it comes to drilling into stucco, having the right drill bit is essential. There are several types of drill bits that are suitable for drilling into stucco, each with its own strengths and applications.

Both diamond and carbide drill bits are effective for drilling into stucco. The choice depends on your specific needs and preferences.

Percussive drilling Surrey comes in several forms, each tailored to specific applications and materials. Let’s explore the three primary types employed in various industries:

This technique is also valued for its versatility in environmental and exploratory drilling, where it can reach hundreds of feet and deal with complex ground formations, removing boulders cautiously while maintaining drilling accuracy.

0086-813-8127573

0086-813-8127573