Ultimate Guide to Milling Tool Holders - cnc tool holder types

High-feed milling creates significant chip thinning due to an extreme lead angle. Feed rates must compensate for this to maximize productivity. The figure at left shows an example of this condition.

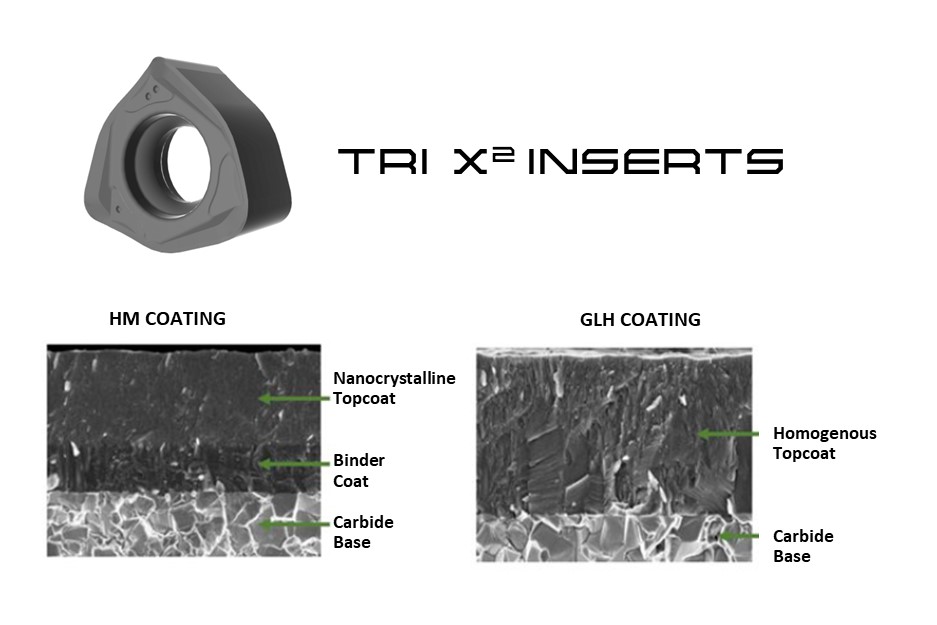

VAPOR™ insert technology includes a positive cutting edge and extra bottom clearance for a smooth chip flow and excellent ramping capability for a double-sided insert. All edges are labeled with “dots” or “dashes” to aid in indexing accuracy.VAPOR™ Tri-X2 inserts include dedicated grades and geometries for a wide range of materials.› “T” geometry for steels, irons, hardened steels› “D” geometry for stainless steels, high-temp alloys

We cannot complete your request due to a technical difficulty. You may return to the previous page or go to the homepage and explore other options. For immediate assistance please call us.

0086-813-8127573

0086-813-8127573