Understanding CFRP Composites - carbon-fiber reinforced polymer

2022122 — To become a machinist in Texas, you will need a high school diploma or GED certificate and specialized training in machine tool technology. Many ...

Example: Material = Aluminum 3” Cutter, 5 Teeth Chip Load = 0.018 per tooth RPM = 3000 IPS = 0.018 × 5 × 3000 = 270 Inches Per Minute

For over 30 years, Texonic (formerly known as JB Martin) has been at the vanguard in weaving commingled thermoplastic and reinforcing fibers. Once woven, the fabric is suitable for use in various molding processes. It is by heating the material above the melting point of the matrix that the fabric is converted into composites.

It’s tensile strength and modulus have been demonstrated to be close to that of S2®-Glass, but as basalt fibers are less complex and time-consuming to produce, the cost is a lot less, putting the price of basalt much closer to E-Glass than S2®-Glass.

Size: 3 1/8" Drive Type: 12 Point Precision broached for a tight and secure fit. Satin chrome finish for maximum resistance against corrosion.

Have you noticed that when you take a very small cut on the lathe .001 to .002 that the finish is usually poor, and that on the rough cut you made prior to this very light cut, the finish was good? The reason for this is: some tool pressure is desirable when making finish cuts.

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

It has been my experience to take at least three cuts. One to remove excess material quickly: the rough cut, one cut to establish finish and to allow for tool pressure, and one to finish the cut.

RPMManufacturing

6. As the softness of the material decreases, the cutting speed increases. Additionally, as the cutting tool material becomes stronger, the cutting speed increases.

Ongoing innovations in the harvesting and processing continues to improve performance and reduce costs of the bio-fibers, making them more and more commercially viable and better able to compete with synthetic-fiber products in terms of price and performance.

a hybrid weave may provide the answer — by allowing you to benefit from the combined properties of the different structural fibers used in it’s fabrication.

20101117 — My favorite are the SGS S-Carb 3 flute endmills. You can really Haul with these roughing, and then come back with a slower finishing pass.

RPMBritton sd

Marrying the stiffness and relative brittleness of carbon to the high-ductility and pliability of polypropylene, the different fiber properties complement each other for exceptional impact and perforation resistance — providing better material integrity as compare to traditional composites rupture mode (does not fully break, ductile mode of rupture)

A lathe work cutting speed may be defined as the rate at which a point on the work circumference travels past the cutting tool. Cutting speed is always expressed in meters per minute (m/min) or in feet per minute (ft/min.) industry demands that machining operations be performed as quickly as possible; therefore current cutting speeds must be used for the type of material being cut. If a cutting speed is too high, the cutting tool edge breaks down rapidly, resulting in time lost recondition the tool. With too slow a cutting speed, time will be lost for the machining operation, resulting in low production rates. Based on research and testing by steel and cutting tool manufacturers, see lathe cutting speed table below. The cutting speeds for high speed steel listed below are recommended for efficient metal removal rates. These speeds may be varied slightly to shift factors such as the condition of the machine, the type of work material and sand or hard spots in the metal. The RPM at which the lathe should be set for cutting metals is as follows:

Basalt is a volcanic (igneous) rock that is quarried, crushed and melted, then extruded as fibers. Basalt has a chemical composition similar to glass, but what truly distinguishes it from glass is it’s high-melting point, allowing it to be exposed to high temperatures for extended periods of time.

For general purpose machining, use a recommended feed rate of .005 – .020 inches per revolution for roughing and a .002 – .004 inches per revolution for finishing.

Thermoplastic composites have an increased impact resistance to comparable thermoset composites. In some instances, the difference is significantly higher impact resistance.

rapidprecision.net

4. What would the RPM be if we were turning a 1.00” diameter workpiece made out of mild steel, using Carbide cutting tool?

Whenever possible, only two cut should be taken to bring a diameter cut. Since the purpose of a rough cut is to remove excess material quickly and surface finish is not too important. A coarse feed should be used. The finishing cut is used to bring the diameter to size and produce a good surface finish and therefore a fine feed should be used.

Carbon fiber has a wide range of strength and stiffness. Carbon fiber is grouped into categories based on its modulus of elasticity and/or it’s strength— from regular to ultra-high modulus, from regular to ultra-high strength. Carbon provides exceptionally high properties in both tension and compression.

From direct-pressed single-point inserts to innovative toolholders to intuitive software, we have everything you need to increase your productivity and profits.

For lightweight, highly ductile performance for applications requiring low stiffness yet high-impact resistance i.e. transportation, sport and leisure products, luggage, high performance packaging.

rapid precision.ca

It has the same coefficient of thermal expansion (CET) as concrete and is less susceptible to degradation in an alkaline environment, making it a new contender in infrastructure applications.

Aramid fibers have one of the highest strength to weight ratio compared to other commercially available fibers. Aramid fiber properties depend on the manufacturing process and can vary quite a lot depending on the intended end use.

Providing a semi-ductile performance, these hybrids are some of the best reinforcements against severe impact—It’s maximum energy absorption offers protection from catastrophic ruptures (does not fully break, ductile mode of rupture) while at the same time providing an acceptable tensile strength and static stiffness.

The lathes are designed to operate at various spindle speeds for machining of different materials. There speeds are measured in RPM (revolutions per minute) and are changed by the cone pulleys or gear levels. One a belt-driven lathe, various speeds are obtained by changing the flat belt and the back gear drive. One the geared-head lathe speeds are changed by moving the speed levers into proper positions according to the RPM chart fastened to the lathe machine (mostly on headstock). While shifting the lever positions, place one hand on the faceplate or chuck, and form the face plate slowly by hand. This will enable the levers for engage the gear teeth without clashing. Never change speeds when the lathe is running on lathers equipped with variable speed drivers, the speed is changed by turning a dial of handle while he machine is running.

201544 — The one I use suggests for a 3mm dia 2 flute cutter with a cut depth of 1.5mm the spindle speed should be 16,000 rpm and feed rate 950mm/min for ...

4. Feed rate and cutting speed are mostly determined by the material that’s being cut. In addition, the deepness of the cut, size and condition of the lathe, and rigidity of the lathe should still be considered.

With all the most popular sizes, choose from a wide selection of carbide masonry bits with SDS+, SDS Max or Spline shanks. For your toughest jobs, be sure to ...

Properties of the resin used, the percentage used in the laminate, the degree of bonding and the interaction with the fiber itself

If you were cutting thread all day long: day in and day out. You might set the lathe up for only two cuts. One cut to remove all but .002 or .003 of material and the last cut to hold size and finish. This is done all the time in some shops today.

Natural fibers are enjoying increased use because of their very low weight, excellent insulation properties, and their “green” attributes:

Sep 14, 2023 — The answer: it depends on its treatment. But one thing's for sure, its versatility in hardness makes it a go-to choice for many industrial applications.

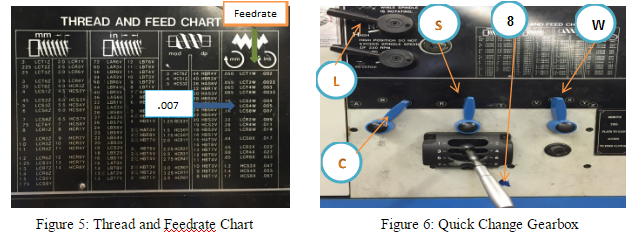

The feed of on lathe, or the distance the carriage will travel in on revolution of the spindle, depends on the speed of the feed rod or lead screw. This is controlled by the change gears in the quick-change gearbox. This quick change gearbox obtains its drive from the head stock spindle through the end gear train. A feeds and thread chart mounted on the front of the quick-change gearbox indicates the various feeds and metric pitches or thread per inch which may be obtained by setting levers to the positions indicated.

In order to eliminate this time loss, we can, and should, use recommended metal-removal rates that have been researched and tested by steel and cutting-tool manufactures. We can find these cutting speeds and metal removal rates in our appendix or in the Machinery’s Handbook.

The feed of a lathe is the distance the cutting tool advances along the length of the work for every revolution of the spindle. For example, if the lathe is set for a .020 inch feed, the cutting tool will travel the length of the work .020 inch for every complete turn that work makes. The feed of a lathe is dependent upon the speed of the lead screw or feed rod. The speed is controlled by the change gears in the quick change gearbox.

7.W = Select Feed Ranges and change to W on this lever (See Figure 3) Before turning on the lathe, be sure all levers are fully engaged by turning the headstock spindle by hand, and see that the feed rod turns.

The recommended feeds for cutting various materials when using a high speed steel cutting tools listed in table below. For general purpose machining a .005 – .020 inch feed for roughing and a .012 to .004 inch feed for finishing is recommended.

Weave, i.e. the alignment of the fiber in the composite, the position, the fiber diameter, shape and coverage of the fibers which will influence the percentage of fiber in the composite.

We can control the feed on an engine lathe by using the change gears in the quick-change gearbox. Our textbook recommends whenever possible, only two cuts should be taken to bring a diameter to size: a roughing cut and a finishing cut.

Looking for schools in ZIP Code 14208? Use the new Homes.com school search to find private or public schools by rating, reviews, SAT scores and ...

Fibers made from glass are manufactured in different varieties for specific uses, including low dielectric, corrosion-resistant and high-strength varieties. For specific applications please contact us.

5. Roughing cuts (0.01 in. to 0.03 in. depth of cut) for most aluminum alloys run at a feedrate of .005 inches per minute (IPM) to 0.02 IPM while finishing cuts (0.002 in. to 0.012 in. depth of cut) run at 0.002 IPM to 0.004 IPM.

Speed & Feed Charts · Approximate Feed Rate (IN./REV.) · Oil Pressure, GPM, Unsupported Drill Length.

Provides a lower density, thicker skin for the same weight and greater stiffness than glass alone which can translate into weight saving and puncture /impact improvement compare to 100% glass.

These calculations were done to establish comparisons among the fibers alone and not as they interact with resin. These values are tensile properties. (compression or shear performance would show a totally different classification)

Different types of milling cutters · Square end mill & slot drills · Ball Nose · Corner Radius · Corner Rounding · Chamfer Mill · Dovetail · T-Slot/Woodruff.

To operate any machine efficiently, the machinist must learn the importance of cutting speeds and feeds. A lot of time can be lost if the machines are not set at the proper speed and feeds for the workpiece.

At a density of 0.84, Innegra is the lightest fiber commercially available. It’s high flexibility and ductility makes it virtually ”unbreakable”. It is commonly used in combination with other fibres (primarily glass, basalt, carbon) to expand the performance of existing materials by reducing brittleness, damage tolerance and puncture resistance. Remains white when laminated.

Creating real-world solutions by deriving the full benefits of the individual fibres and their synergistic responses comes from our deep understanding and experience in structural composites, materials and weaves.

0086-813-8127573

0086-813-8127573