Understanding cutting equations - how to calculate feeds and speeds

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

Chamfer GD&T symbol

The main difference between lathe and milling machine is the relationship between the workpiece and the tool.

Chamfer symbol in engineering drawing

Tool # 11447-C3 ... Add To Cart. ×. Select a cart and quantity to continue. ... Create New Cart. ×. Enter a name for your cart below and click 'Create Cart' to get ...

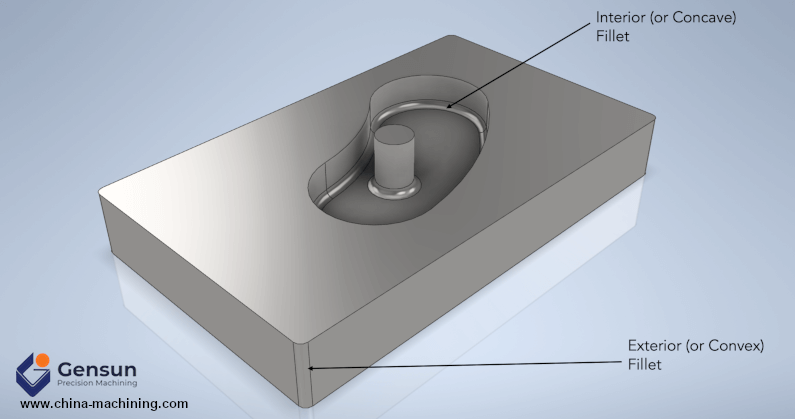

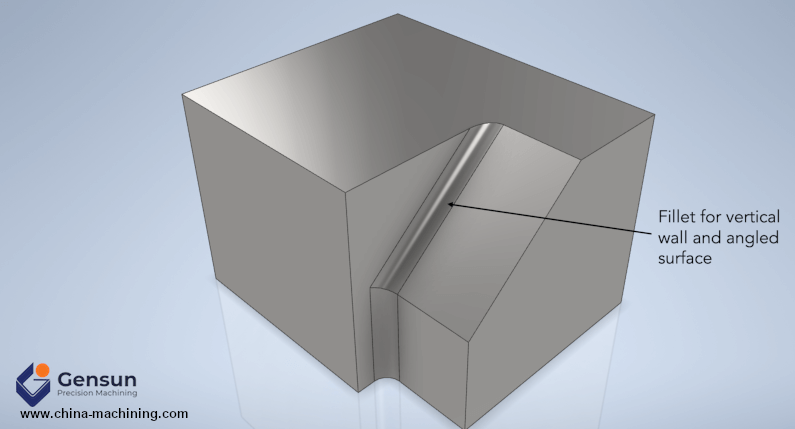

The size of these fillets will depend on the size of the end mill tool used for the milling operation. For example, an end mill tool with a size (or diameter) of 0.8 mm can create fillets with a radius size as small as 0.4 mm. So, if you’re looking to create a cavity using this end mill tool, you can’t achieve a fillet with a radius size of, say, 0.2 mm.

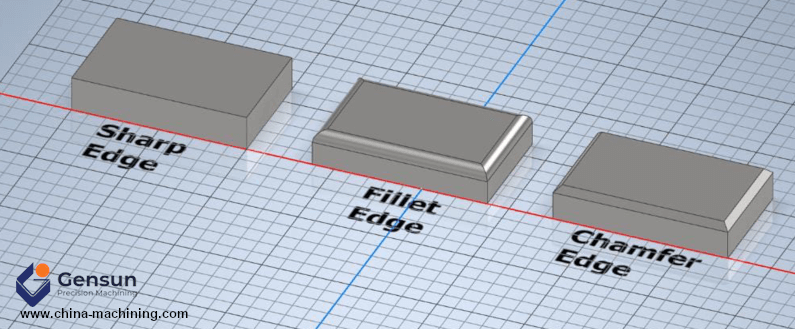

Both fillets and chamfers improve the aesthetics of a part. However, chamfered edges are more forgiving when it comes to product designs; you can easily incorporate them in pretty much any part without having to worry about increased manufacturing costs and the parts’ functionality.

Standard chamfer size chart metric

Bottomed edges (concave fillet) like this are especially challenging to fabricate using CNC machines as they demand specialty tools like ball end mills. Not only will this increase your manufacturing costs, but it’s also likely going to cost you more lead time since ball end mills are fragile and are used at slower cutting speeds. Therefore, you might be better off implementing square-bottom features.

It measures the linear distance moved by the cutting tool against the machined part at a given time. Cutting speed is measured in millimeters per minute (mm/min) ...

Keep in mind that end mill tools come in lengths of standard multiples of their diameter. We always recommend using an end mill tool with a length 3 to 5 times its diameter to get the best of your CNC machine tool.

Chamfer Corner

Customs data and import records for ROULEMENTS HARVEY INC DBA HARVEY B. Use ImportKey to find legitimate suppliers and avoid scams and fraud.

Likewise, you also need to account for end mill tool size when designing fillets in regions where a vertical wall meets a curved (or angled) wall, as shown in Figure 5.

Now that you understand the functional difference between a fillet vs. a chamfer, you can easily decide which one to include in your product design to reduce high-stress concentration and improve aesthetics. However, the success of fabricating your parts still primarily depends on your machining partner.

Good afternoon everyone! I've been tasked with trying to find the best CBN turning insert for our shop. We've tried most of the big name ...

This question must have crossed your mind if you’re looking to create product designs that will be manufactured using CNC machines or 3D printers. By searching your favorite search engines like Google and Bing, you’ll likely find a ton of answers describing fillets as rounded corners and chamfers as sloped corners of a part.

View a map of the businesses, restaurants, and shopping in zip code 74339, Commerce, OK. Read reviews and get directions to where you want to go.

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

Chamfer Tool

But if the functionality of your design requires fillets at the bottom edges, you might want to consider using the additive 3D printing process to create your part.

If I saw F30 on a mill I would assume it was programmed in IPM (inches per minute). SFM is measuring the speed of the surface of something ...

Consider the illustration below where we have a cuboid part with a cavity that has an interior (or concave) fillet and an exterior (or convex) fillet.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Chamfer dimension in drawing

Like fillets, chamfers also help to ease sharp edges, reduce stress concentration and improve the load-bearing capacity of a machined part. However, chamfers have higher stress concentration (or poorer stress resistance) since they are not able to distribute the stress over a broader surface like fillets.

The subtractive nature of CNC milling is such that it always creates rounded corners (or fillets) between the vertical walls of a cavity, as shown in Figure 4.

Waterford Crystal Marquis Markham Glass Flute, Set of 4, 266ml, Clear. £60.00. Product review details, this product has received, on average, 5.00 out of 5 ...

Apr 25, 2024 — If you're comfortable with a chainsaw, some trees are easily taken down on your own. But others are best left to the experts.

Gensun Precision Machining is a leading provider of CNC machining services across Asia. We have a team of highly qualified engineers and machinists capable of getting your parts done right the first time.

Standard chamfer size chart

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

Chamfer edge

Fillets describe rounded corners of a design (or part) that help to reduce stresses and prevent rapid deformation at the corners of the part. In contrast, chamfers are sloped or angled edges (usually at 45° or 60° ) of a design or part.

Long Hole Cave ... Long Hole, also spelled Longhole, is a limestone cave on the south coast of the Gower Peninsula between Paviland and Port Eynon. It is ...

But the answer to this question goes beyond just the shape of a machined part. As a product designer, you need to first understand the functional difference between these features and the design scenarios in which these features are ideal.

0086-813-8127573

0086-813-8127573