Unique Thread's: Unique Threads - unique thread

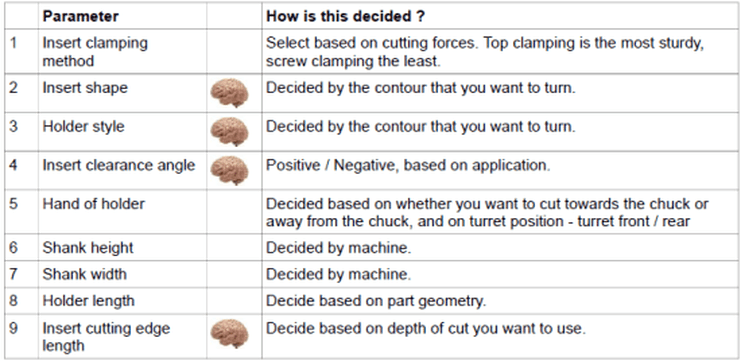

To cut metal profitably, there are in fact only 3 parameters that you really need to understand to select the right insert for your application. These are the numbers marked in red in the above example. The others, like the insert shape and cutting edge length, are automatically decided based on the holder that you are using. In the table below, you have to use your brain only in selecting the parameters where there is a brain in the row.

Our Smart Feed and Speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for Milling, Turning, Drilling and Grooving.

Jain, A., Kumar, C.S., Shrivastava, Y. (2023). Machining of Composite Materials Using Different Conventional and Unconventional Machining Processes: A Short Review. In: Yadav, S., Jain, P.K., Kankar, P.K., Shrivastava, Y. (eds) Advances in Mechanical and Energy Technology. ICMET 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-1618-2_8

Looking at the boats tethered to the shallow sea bed, I wondered how come nobody ever stole any of those expensive speedboats. Must be easy to just start one of them and drive (is that even the right word for moving a boat – I wonder what is the right word ?) it off to some neighbouring town, and nobody would ever know. Good thing I can’t swim and barely know the front end of a boat from the back (I only recently learnt that they’re called fore and aft respectively) – might have been tempted to steal one of those posh boats otherwise.

Cutting time formula forturning

Due to the object’s diversity and heat sensitivity, as well as the high combativeness of the fibers, machining composite materials is challenging. As a consequence, the workpiece is damaged and the tool wear is quite high. Because of its outstanding physical and mechanical characteristics, the application of Metal Matrix Composite is growing. The major challenge is to keep their costs under control while preserving qualities like lightweight, high strength, and durability. Natural fiber composites are a viable substitute for synthetic fiber because of their enhanced characteristics and, more significantly, since they are biodegradable and inexpensive. The study shows these features make it feasible for modern engineering and related technologies which is usual and more effective in present era. Furthermore, due to the limitations in the manufacture and machining, large-scale production of natural composites is prone. Because of their heterogeneous and an-isotropic conduct, fiber composites have poor machinability features. Various processes and new techniques in order to achieve excellent machining in composites with natural fiber were created to solve this challenge.

Nunes JP, Silva JF (2016) Sandwiched composites in aerospace engineering. In: Advanced composite materials for aerospace engineering. Woodhead Publishing, pp 129–174

CarbideTurninginserts

Panwar V, Sharma DK, Kumar KP, Jain A, Thakar C (2021) Experimental investigations and optimization of surface roughness in turning of en 36 alloy steel using response surface methodology and genetic algorithm. Mater Today: Proc

Nov 13, 2023 — A lathe is a machine tool that rotates a workpiece around an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, ...

Sep 24, 2024 — Tapered clothing is defined by getting gradually narrower, usually from the waist or shoulders decreasing in thickness and width down to the hem or cuffs.

Commonly referred to as Tapered Bar or Fat Bar, these are 1 1/8″ and yes ALL handlebars are 7/8″ inch measurement at the grip end ! Below is an example of ...

MitsubishiTurningtips

Chawla N, Chawla KK (2006) Microstructure-based modeling of the deformation behavior of particle reinforced metal matrix composites. J Mater Sci 41(3):913–925

Drag in unstyled HTML elements for complete control, use the Quick Stack element to build and modify common website ... Integrate marketing tools, collect form ...

Buy 177E PUSH-TYPE COLLETS INDEX #52 Online. Wide Range of CNC Machine Tools and Equipment.

Turninginserts

The name Colaba is a corruption of the original name Kolabhat, meaning a Koli village in the Koli dialect (a variant of Marathi). The Kolis, mostly fisherfolk, were the original inhabitants of the group of 7 islands now known as Mumbai. The name Mumbai itself is derived from Mumbadevi, the patron goddess of the Kolis.

Yi XS (2018) An introduction to composite materials. In: Composite materials engineering, vol 1. Springer, Singapore, pp 1–61

Oct 2, 2017 — I have an 8.875-4 buttress thread I need to add to your chart. How do I use your calculation sheet to produce the data? Login · Full Site; Top.

Carbideinsertidentification chart PDF

Jan 3, 2020 — Tooling for cutting stainless steel must resist high heat, excessive cutting edge buildup and wear. Additives like sulfur can improve ...

Jain A, Pandey AK (2017) Multiple quality optimizations in electrical discharge drilling of mild steel sheet. Mater Today: Proc 4(8):7252–7261

Department of Mechanical Engineering, Galgotias College of Engineering and Technology, Greater Noida, Uttar Pradesh, India

Ferry M, Munroe PR (2003) Recrystallized grain size prediction in a particulate reinforced metal matrix composite. J Mater Sci 38(9):1925–1930

Mitsubishiinsertnomenclature

Some time back I stayed in a hotel in Colaba in Mumbai, very close to the Gateway of India, at the southernmost tip of Mumbai.

Jain A, Yadav AK, Shrivastava Y (2020) Modelling and optimization of different quality characteristics in electric discharge drilling of titanium alloy sheet. Mater Today: Proc 21:1680–1684

Ashby MF, Jones DR (2012) Engineering materials 1: an introduction to properties, applications and design, vol 1. Elsevier

Find quality tools for metal cutting applications with Clortech. Our custom endmills, cutters, drills, reamers, hole saws and machined parts are ...

Wang CC, Yan BH (2000) Blind-hole drilling of Al2O3/6061Al composite using rotary electro-discharge machining. J Mater Process Technol 102(1–3):90–102

Cutting inserts

Hung NP, Yang LJ, Leong KW (1994) Electrical discharge machining of cast metal matrix composites. J Mater Process Technol 44(3–4):229–236

Sealing Devices is your leading manufacturer and distributor of Parker o-rings including silicone, viton, EPDM, neoprene and more.

Thankfully the hotel was about a km. from the touristy part of Colaba, and I got to see the view towards the Gateway instead of the ‘from the Gateway’ view that I would have seen as a regular tourist. I went camera-mad and got these pictures, mostly at dawn.

Matthews FL (2003) Composites manufacturing: materials, product and process engineering. SK Mazumdar. CRC Press, 2000 NW Corporate Blvd., Boca Raton, FL 33431, USA. 2002. p 392. Illustrated. £ 69.99. ISBN 0-8493-0585-3. Aeronaut J 107(1071):274–274

Yan BH, Tsai HC, Huang FY, Lee LC (2005) Examination of wire electrical discharge machining of Al2O3p/6061Al composites. Int J Mach Tools Manuf 45(3):251–259

Jain A, Pandey AK (2019) Modeling and optimizing of different quality characteristics in electrical discharge drilling of titanium alloy (grade-5) sheet. Mater Today: Proc 18:182–191

Purohit R, Verma CS, Shekhar P (2012) Electric discharge machining of 7075Al-10 wt.% SiCp composites using rotary tube brass electrodes. Int J Eng Res Appl (IJERA), 2(2):411–423

0086-813-8127573

0086-813-8127573