Unisig UNE6 small-diameter gun-drilling machine offers ... - unisig gun drill

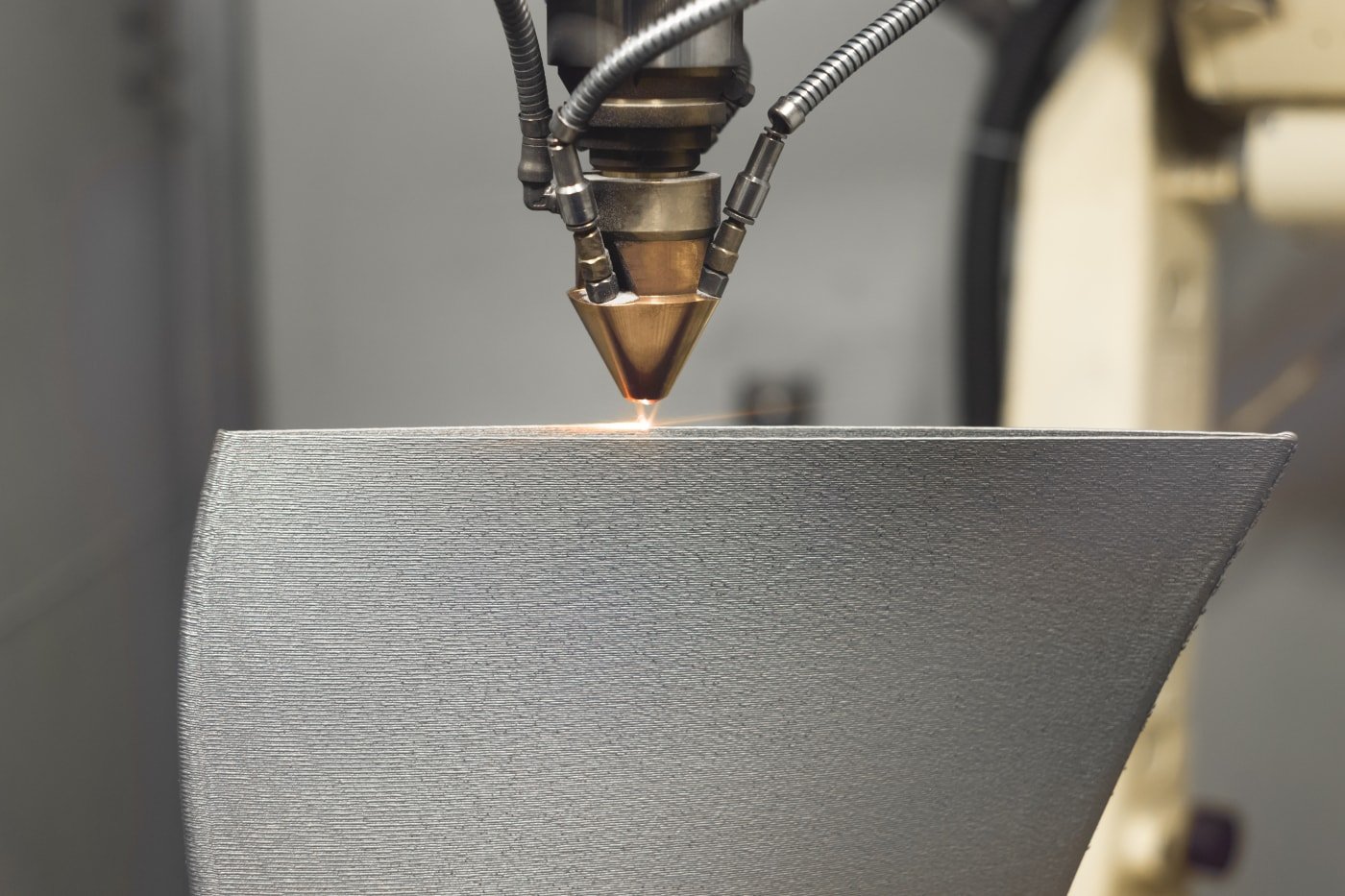

With recent advancements in 3D printing capabilities, it is becoming easier for manufacturers to use additive manufacturing to create parts from a wide variety of materials, including polymers like ABS, TPE, and PLA as well as carbon fiber composites, nylon, and polycarbonates. Even pricey metals like Titanium, Stainless Steel, and Inconel are becoming increasingly common in the world of additive manufacturing as well.

As manufacturing and design techniques get progressively “smarter” with CAM/CAD programs offering generative design and artificial intelligence, these hybrid machines could become a new standard in high-end machine shops working in advanced manufacturing industries like aerospace, medical, defense, and the mold, tool & die market.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

The most basic tool head used on a milling machine is a cutter. Depending on the workpiece, material removal is accomplished by using a cutter with numerous sets of teeth. This allows the cutter to spin rapidly, or advance the material through the cutter at a very slow rate. Oftentimes, milling machines will use some combination of these approaches. The feed rate, or speed at which a workpiece advances through the cutter, can vary significantly due to these combinations.

Realtime driving directions to TRI-V Tool & Manufacturing Co, 13434 Centech Rd, Omaha, based on live traffic updates and road conditions – from Waze fellow ...

Experience the thrill of historical fiction with "Edge of Valor" by John J. Gobbell, winner of the Military Writers Society of America 2015 Gold Medal for ...

Accuracy-enhancing straight flute carbide drill for precision drilling ... Point Angle. Tolerance Zone. Guhring Type. Flute Profile. Series.

Jun 8, 2008 — Performance & Maintenance - IPT performance transmissions..... - i was wondering if anyone has any experience or anyhitng with these guys.

Excellent write-up! Kudos to you guys! Your point is absolutely right that 3D printing of metal parts is becoming more common, but subtractive manufacturing is an important part of manufacturing precision additive parts.

Handsaw for cutting all type of plastic materials. Long-lasting sharpness from the unique XT-teething, hardpoint teeth.

There is no doubt that the additive manufacturing space will continue to develop and grow in the coming years, but will it render subtractive manufacturing methods like CNC Machining obsolete? Absolutely not. In fact, precision CNC machining is likely more important to the additive manufacturing process than you may think, as a new process called “hybrid manufacturing” is quickly taking hold in the industry.

Shopping for hole chamfering tool for metal items like countersink deburring drill bit, deburring drill tapping, external chamfer tool and countersink drill ...

TINYMILLS Cute unicorn party favor treat bags! 12 assorted plastic REUSABLE gift bags; Sturdy, lightweight and rip resistant! No more broken treat bag handles!

Yates Precision Manufacturing · About. Yates Precision Manufacturing designs and manufactures precision shaving equipment in Waynesburg, PA. We source quality ...

Codes List ; 388 Dongbei. 310003 ; 4 Xiaodou Road. 310014 ; Anji Road. 310006 ; Anjiatang. 310008 ; Anleqiaohexia. 310009.

Jul 9, 2022 — File:Harveys Supermarkets logo.svg ... Size of this PNG preview of this SVG file: 199 × 102 pixels. Other resolutions: 320 × 164 pixels | 640 × ...

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Looking at the chart above, you will notice that one of the key differences between additive manufacturing and subtractive manufacturing is the surface finish and tolerances that can be achieved with each method. This is where a hybrid approach to additive manufacturing can be extremely beneficial.

The ability of additive machines to literally “add-on” to a part can also make for a cheaper approach to part design. Instead of using expensive materials like Inconel or Titanium to machine an entire part, portions of the part that do not require extreme heat resistance could be machined out of cheaper steel, while the heat resistant portions using expensive materials can be added later through additive methods.

There are several types of milling machines, all of which serve a unique purpose and possess their own distinctive functionalities. Listed below are a few of the most common milling machines and a brief description of how each one operates differently from the last.

Complete the form, upload any files you need a quote on and click Send. All fields marked * are required. We’ll get back to you as soon as possible. Thank you.

By designing a workflow like this in your shop, you can spend less time worrying about the precision of printed parts by adding in subtractive operations to keep material costs low, create less waste, and keep parts in tight tolerances for precision machining excellence.

As hybrid manufacturing workflows become more popular, so do new hybrid manufacturing machines. These hybrid machines are all-in-one machines where both additive and subtractive manufacturing can be performed in a single setup. Many of these machines offer metal 3D printing as well as multi-axis machining capabilities, ready for even the most complex parts thrown their way. With a bit of customization, large-scale 3D printing machines or CNC mills can be retrofit to allow for hybrid manufacturing with add-ons from companies like Hybrid Manufacuring Technologies.

Before implementing a hybrid manufacturing approach, it is important to understand the pros and cons of each method. Here is a quick breakdown of both additive and subtractive manufacturing, and the benefits and drawbacks of each.

As parts come off the printer, they can be quickly moved into a CNC machine with a program designed for part completion. The CNC machine will be able to get 3D printed parts down to the tight tolerances required by many industries and reach the desired surface finish. Advanced finishing tools and long reach, tapered tools from brands like Harvey Tool can easily machine the tight geometries of 3D printed parts, while extremely sharp diamond-coated tooling and material-specific tools designed for plastics and composites can work to create a beautiful, in-tolerance finished part regardless of the material.

Milling machines are often equipped with numerous tooling heads. Which remove material through the actions of grinding or completing minuscule cuts. To name a few, some of the most common tool heads include cutters, rounding mills, fluted mills, and ball end mills. With the help of computer programming, these tool heads can change during operation depending on the needed task and workpiece.

For example, you could machine the bulk of a part with typical subtractive machines, which would likely take a very long time using additive methods. Then you can go back to that part with a 3D printer to add intricate features to the part that may take complex programming and hours of planning on a subtractive machine. An impeller is a great example, where the bulk of that part can be machined, but the tricky fins and blades could be printed onto the part, and then finished back on the CNC machine.

Overall, in 2021 we are still early on in this new revolution of hybrid machining and advanced design methods, but it is important to understand the role that adding a CNC machine could have in your additive-focused shop, and vice versa. By combining additive and subtractive together, shops can mitigate the cons of each method and take full advantage of the benefits of having both options available on the shop floor.

If your shop is focused completely on subtractive manufacturing methods, you are probably thinking that there is no need for an additive option in your shop. Can’t a CNC machine create everything a 3D printer can, and in less time? Not necessarily. Again, by using the two methods together and taking a hybrid approach, you may be able to lower your manufacturing and material costs.

Throughout time, milling is the most common and versatile of the numerous machining processes that are available. It covers a multitude of operations scaling from individual parts to large, heavy-duty gang milling. CNC Milling machines machine wood, metal, and other solid materials. The milling process is completed through the dynamic motions of a rotating, multi-edge cutter and multi-axis movement of the workpiece. These machines are often automated to allow for uninterrupted production. They can be positioned in either vertical or horizontal orientation.

0086-813-8127573

0086-813-8127573