Unit 2: Speed and Feed – Manufacturing Processes 4-5 - cutting speed chart

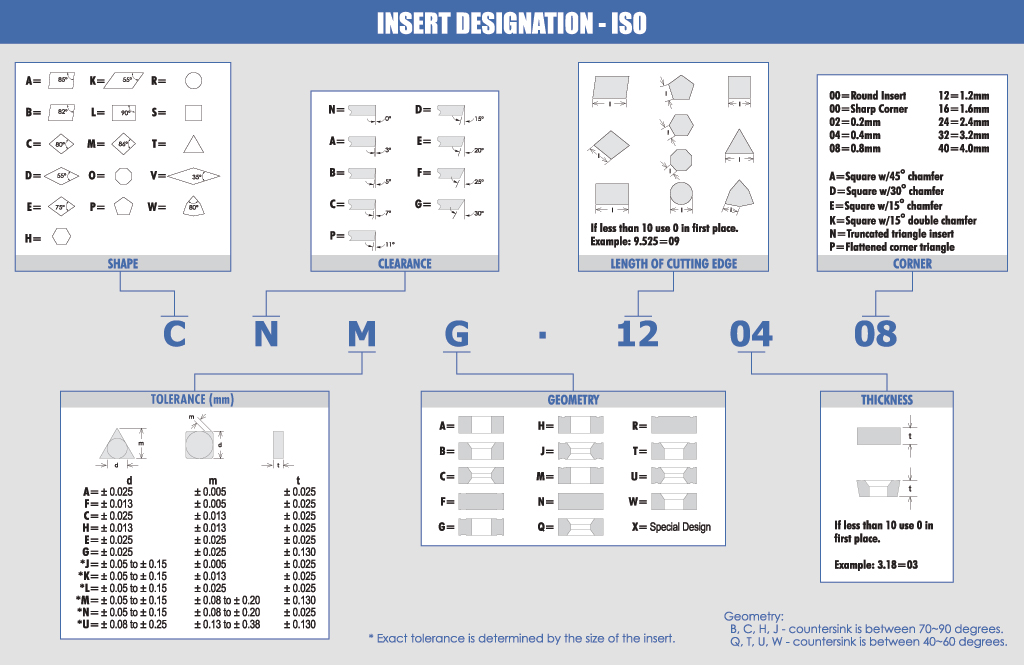

ISOinsertnomenclature pdf

Manual processes are time consuming and hold the serious risk of errors. Undisputed one of them is the tracking of design changes: often a manual,...

Control & Inspection Planning (CP&IP) as part of quality planning is one important module of the Teamcenter Quality solution from Siemens Digital...

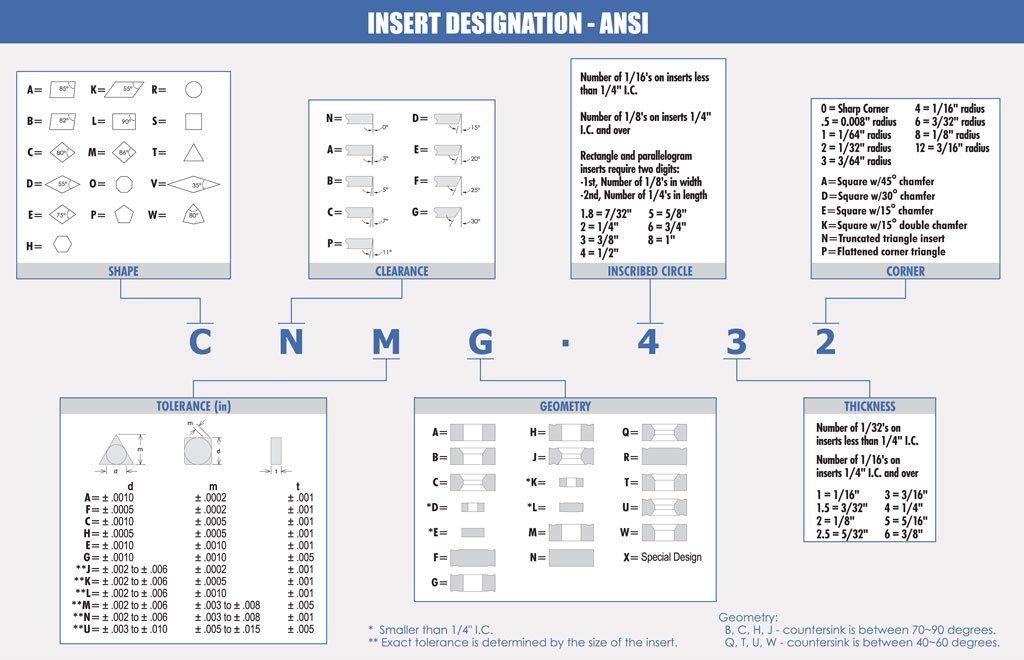

Carbideinsertsize chart

The inscribed circle (IC) is not something you can readily measure on a triangular insert. But the height (H) is easy to measure (a flat against one jaw of your caliper and a point against the other). The diameter of the inscribed circle is 2/3 of that measurement. So if you measure the height of an insert to be 0.374 (the radius on the point makes it a little less than the true height), the calculated inscribed circle is 0.249, or 1/4".

In our article "Effective PMI Management with NX Hole Callouts" we gave a first introduction about NX hole callouts, the associative descriptions/labels for holes and threads, which are created from multiple parameters, derived directly from the hole's feature data. Read in our blog which additioanl parameters are available and how the NX hole callouts are ballooned for inspection.

ISOinsertchart

Turning insertIdentification chart

ISOturning insertnomenclature

Each individual hole callout parameter (FLL, diameter, dimension, angle, note) is assigned a unique sub-balloon number (sub- or integer numbers), taking into account the default tolerances, e.g.

Working in design engineering with NX, the solution from Siemens Digital Industries Software, provides the functionality of so called "NX hole...

A hole callout is a new characteristic type that can be ballooned within BCT Inspector, the quality management solution for NX and Teamcenter. The hole callout characteristic is similar to a text note: the remark column contains the whole callout content as text. Each hole callout / feature type (hole, drill size hole, screw clearance hole, ...) receives one main charateristics number, e.g.

FLLs manage additional referenced features of a PMI (Product Manufacturing Information). In the quality process, there is a need to identify and measure each of these elements, identified by its exact position. To fulfill this specification, it is necessary to place identification labels on each of these occurrences (pattern feature count). FLLs will be applied according to number of associated objects on a PMI hole callout, e.g.

These tables show the ANSI and ISO insert designations for indexable inserts for turning. A given insert can be specified in either ANSI (American) or ISO (metric) designations. Because many inserts are made in other countries, the ISO system is used frequently. Don't get hung up with spaces and hyphenation in insert designations. They are sometimes included for clarity, but there is little consistency among vendors.

Carbideinsertidentification chart PDF

The secondary dimension for depth creates an additional Hole Callout for depth. During ballooning it will be handled as a separate hole callout. A new main characteristic number will be assigned, parameter(s) will get sub-numbers assigned. Restriction: if depth parameter is visible on the linear/radial hole callout a separate sub-number will be assigned.

The first digit (fifth character) of the ANSI designation is the size, described by the inscribed circle. This illustration shows what that means.

See also: Indexable inserts available at LittleMachineShop.com ANSI Turning Tool Designations ANSI Boring Bar Designations

0086-813-8127573

0086-813-8127573