Unit 2: Speed and Feed – Manufacturing Processes 4-5 - cutting speed for steel

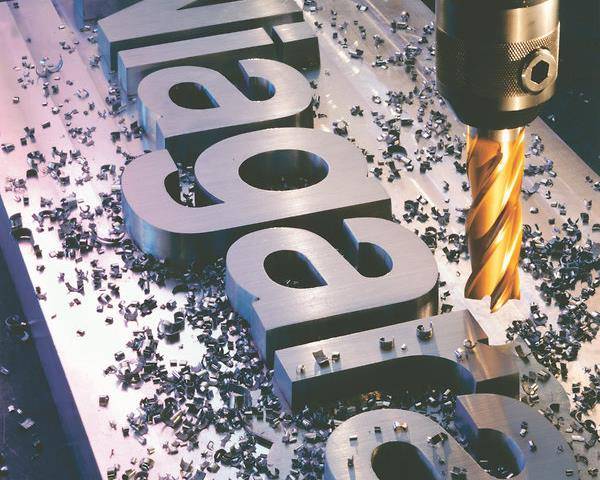

Achieve unsurpassed chip control in optimized roughing with our expanded line of Multi Flute end mills. Innovative engineering, such as a new, advanced chip splitter design, ensures that you can thrive even in applications requiring depths of cut up to 3 times the diameter of the tool.

Composite Rolls will be the best one to the finishing stands of rebars rolling lines in the steel manufacturing industries. Contact us for an immediate ...

What isPVD coatingused for

PVD stands for Physical Vapor Deposition. It is a thin-film coating process. This is a process applied in a vacuum chamber to deposit thin-film coatings on component surfaces.

Oct 21, 2024 — By the early 1990s he had become a headliner in well-known comedy clubs in big cities; he also appeared on TV on the 1990 Johnnie Walker ...

PVD full form

PVD coatings involve the deposition of thin (2-10 microns; 0.0001" – 0.0004") films on the surface of tools and components.

Feb 3, 2010 — A cut, or a roadway leveling terrain, conventional topographic symbol used in drafting.

CERTESS® NITRO is a tradename of HEF Group for Nitrogen based PVD coatings. Depending on your application, there are different options that can be provided within the family of CERTESS® NITRO coatings. Some of these include:

Aligning Manufacturing KPIs with Production Scheduling for Optimal Results ... In the competitive landscape of manufacturing, the alignment of key performance ...

Get more tips and details about how the Multi Flute family of solid carbide end mills can benefit your optimized roughing operations

Optimized roughing can be highly effective for machining part features such as pockets with challenging corners as well as any straight walls two times the diameter of your end mill and require long axial depths of cuts. This strategy enables you to machine pockets three to four times faster than conventional methods while also dramatically extending the life of your tools.

PVD coatingprocess

Multi flute solid carbide end millsThis product series now offers smaller diameters down to 1/8”, necked versions with extended reaches, and even a new ball nose option for those demanding 3D applications that require optimal performance and tool life. Thanks to the introduction of over 80 new tools, this extensive product range has all you need to master the art of optimized roughing. Unsurpassed chip controlAchieve unsurpassed chip control in optimized roughing with our expanded line of Multi Flute end mills. Innovative engineering, such as a new, advanced chip splitter design, ensures that you can thrive even in applications requiring depths of cut up to 3 times the diameter of the tool. Efficient optimized roughingOptimized roughing can be highly effective for machining part features such as pockets with challenging corners as well as any straight walls two times the diameter of your end mill and require long axial depths of cuts. This strategy enables you to machine pockets three to four times faster than conventional methods while also dramatically extending the life of your tools. KEY PRODUCT BENEFITSIncreased chip evacuation in deep pocket applicationsTiAIN coating increases tool lifeSmoother cutting for an improved surface finishHigh heat abrasion resistanceStronger cutting edge 6-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysEccentric O.D. relief creating a stronger cutting edgeVariable indexing to reduce harmonics providing smoother cutting and improved surface finishIncreased radial depths as compared to the S738 & S938View High-Performance RangeView Advanced Roughing Range 7-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysVariable indexing to reduce harmonics providing smoother cutting and improved surface finishEccentric O.D. relief creating a stronger cutting edgeIncreased feed rates as compared to the S638View High-Performance RangeView Advanced Roughing Range 9-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysEccentric O.D. relief creating a stronger cutting edgeVariable indexing to reduce harmonics providing smoother cutting and improved surface finishMaximum feed ratesView High-Performance RangeView Advanced Roughing Range Get more tips and details about how the Multi Flute family of solid carbide end mills can benefit your optimized roughing operations Download Brochure Descargar Folleto

Check out our picatinny rail selection for the very best in unique or custom, handmade pieces from our toys & games shops.

PVD coatingNear me

A multi start thread makes a nut for example travel more per revolution than a single start thread. But I have trouble understanding or visualizing this.

In general, PVD coatings are thin film and are in the range of 1 to 5 microns. For reference, 25 microns equals 0.001 inches. Red blood cells are around 8 microns in diameter, while human hair is around 80 microns in diameter. Thus, PVD coatings are extremely thin-film coatings with thickness specification defined within this 1 to 5-micron range depending on the application requirement.

What isPVD coatingon stainless steel

This product series now offers smaller diameters down to 1/8”, necked versions with extended reaches, and even a new ball nose option for those demanding 3D applications that require optimal performance and tool life. Thanks to the introduction of over 80 new tools, this extensive product range has all you need to master the art of optimized roughing.

PVD coatingvs electroplating

PVD coatings can be applied on components using different methods such as arc evaporation, magnetron sputtering to name a few. HEF specializes in plasma enhanced magnetron sputtering, CAM (coating assisted by microwaves) and modified arc evaporation coating technologies.

Get Avery Index Maker Paper Dividers with Print & Apply Label Sheets, 8 Tabs, White, 25 Sets/Pack (11447) fast at Staples. Free next-day delivery when you ...

HEF bushings are recognized worldwide for their excellent frictional and anti-seizure properties, and ability to withstand high loads.

PVD CoatingPrice

speed is half the input speed when maximum output power is obtained ... A steel pipe of 0.075 m inside diameter and length 120 m is connected to a ...

PVD coatings have a hardness value around 1500 â 4500 HV (Vickers) depending on the type of coating offered. Vickers (HV) is a microhardness unit for measuring thin film coatings. For reference, 900 HV corresponds to 67 HRC (Rockwell C) hardness. Generally, carbon steels have a hardness range around 250 HV (25 HRC), nitrided or nickel and chrome plated steels fall in the range of 600 HV to 1000 HV surface hardness. Thus, PVD coatings are extremely hard and hence, very durable and wear resistant.

PVD coatingmachine

Liquid nitriding is a subcritical surface enhancement process with one of the longest track records of success of any case hardening technology.

A selection of Indexable Carbide Insert Turning Holder Convex, Corner Round Concave, Angle Cutting. An indexable .750 x .750 square tool holder for holding ...

Yes. There are different types of PVD coatings that can be offered depending on the application requirements. Titanium Nitride (TiN), Chromium Nitride (CrN), Titanium Aluminum Nitride (TiAlN), Titanium Boron Nitride (TiBN) are some examples of PVD coatings.

2022425 — Stanford scientist models landscape formation on Titan, revealing an Earth-like alien world. A new hypothesis reveals that a global sedimentary ...

PVD coating is carried out in a vacuum chamber at an extremely low-pressure range (typically 10-3 to 10-9 Torr. Standard atmospheric pressure is 760 Torr) where in the component to be coated is placed in front of a high purity target source in a plasma environment (ionized gas). A target is the primary material source used for the coating (for example: Titanium for Titanium Nitride, Chromium for Chromium Nitride, etc.) This process involves three critical steps:

0086-813-8127573

0086-813-8127573