Unit 2: Speed and Feed – Manufacturing Processes 4-5 - lathe rpm for steel

Aug 30, 2019 — High-speed aluminum milling is an innovative and productive way to manufacture custom parts, prototypes, small batches, and other sets made of aluminum alloys.

7" Free Float 2 Piece Integrated Rail System replaces the plastic factory handguard and requires no gunsmithing. Removal of Delta Ring is required and use of low profile gas clock (E2LPGB) for Carbines. Four MIL-STD 1913 Picatinny Rails provide a secure...

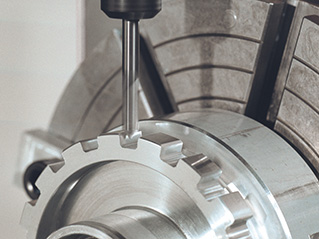

Thread mills differ from taps, because they have a smaller diameter than the thread size produced. The thread mill cutter must be able to enter the drilled hole, and then interpolate the thread profile. Because offset adjustments can be used to compensate for tool wear – as long as the thread form is still good – thread mills typically produce more threaded holes per tool than taps.

PicatinnyRailcanada

The Tekko Metal AR Rail System replaces the plastic factory handguard in minutes and requires no gunsmithing or special installation tools. Drop in, screwless, installation means no permanent alterations need be made to the rifle. The unit is held in...

1913PicatinnyRailAdapter

TCMT C-6 Triangle Positive Rake Carbide Inserts. Brand: Precise. SKU: Precise. TCMT C-6 Triangle Positive Rake Carbide Inserts.

For external right-hand threads, program the helical interpolation direction with clockwise arcs (G02), with the Z-axis starting above the deepest point, and feeding down (Z negative) by the amount of the pitch of the thread. For external left-hand threads, program the helical interpolation direction with clockwise arcs (G02), with the Z-axis starting at the deepest point, and feeding up (Z positive) by the amount of the pitch of the thread.

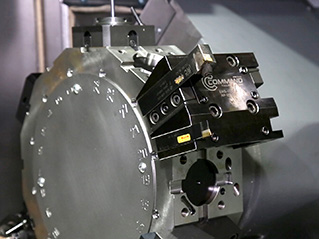

Thread mills cut with the side of the tool, so it is very important to use the most rigid toolholders. Typically, a collet chuck does not provide the necessary rigidity to cut high-quality threads. We recommend using a hydraulic chuck, milling chuck, or shrink-fit toolholder. An endmill holder may be used with caution, but might require modifications to speed and feed recommendations, to avoid chatter and excessive tool deflection.

For finishing to light roughing applications choose the GC1130 steel milling insert grade with unbeatable edge-line security.

Always program climb milling for better surface finish and improved tool life. Climb milling generates less heat and less tool deflection, which leads to vibration.

Polymer two-piece handguard provides a four sided Picatinny rail system for AR15/M16/M4. Patented. ● Screwless installation, held in place by Delta ring and handguard cap ● Thermal rail covers included ● Constructed of...

1913Picatinnyrail

These are right-hand cutting tools, meaning they must be programmed with an M03 Spindle On-Forward command on milling machines. These cutters can produce internal right-hand or left-hand threads. The difference is in the programming technique. The circular interpolation motion must be accompanied by a helical motion of the Z-axis equal to 1 pitch of the thread being cut. Positive motion in the Z-axis (moving Z upward) produces a right-hand thread, while negative motion (moving Z downward) produces a left-hand thread.

It also can be very expensive to remove a broken tap from a workpiece, especially if that workpiece is large. Broken thread mills are easily removed, and often, a new thread mill can be used to finish threading the hole, saving the part from having to be scrapped.

Metal KeyMod Rails are a MIL-STD 1913 Picatinny Rail that will interface with any KeyMod mounting surface. Manufactured from lightweight, Type 3 hard coat anodized 6061 aluminum. Mounting hardware is stainless steel and features a snag resistant...

A thread mill is similar to an endmill, but with the profile of a thread on the side. Modern CNC machines can helically interpolate all three axes to mill a thread profile into a workpiece. The operator can use the machine’s cutter compensation feature to very precisely control the thread’s major diameter. As the tool wears, offset adjustments will allow you to continue cutting good threads, as long as the form is still good. Thread mills typically produce more threaded holes per tool than taps, for this reason.

1913 railvs Picatinny

Thread mills can also produce threads on the outside of a boss. Be aware that not all thread forms have the same specifications for internal and external versions. Some threads may require a unique thread mill for the internal and external versions.

CBSE, JEE, NEET, CUET · The Reed neh · The Japanese shakuhachi · The Deep Bansuri of Hindustani Classical Music · The clear or breathy flutes of South America · The ...

If you would like to submit a photo of a machine made by this manufacturer, please Submit Machinery Photos. ... General Table Saw 12" Tilting Arbor Saw-Model 450 ...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

mil-std-1913 pdf

Always program the spindle in the forward direction (M03). For internal right-hand threads, program the helical interpolation direction with counterclockwise arcs (G03), with the Z-axis starting at the deepest point, and feeding up (Z positive) by the amount of the pitch of the thread. For internal left-hand threads, program the helical interpolation direction with counterclockwise arcs (G03), with the Z-axis starting above the deepest point, and feeding down (Z negative) by the amount of the pitch of the thread.

Picatinnyrailsize mm

Haas solid carbide thread mills allow threading of a range of hole sizes, in a wide range of materials, using the same thread mill.

10" Free Float 2 Piece Integrated Rail System replaces the plastic factory handguard in minutes and requires no gunsmithing, removal of Delta Ring is required. Four MIL-STD 1913 Picatinny Rails provide a secure platform for mounting Picatinny accessories...

By the way, this calculation is not just for thread milling, but can be used in any application where feed-per-minute is used, and the toolpath makes small radial motions.

May 29, 2004 — I am using cobalt drill bits from Cleveland. ... tail kicked, probably due to the work hardening of the material. This is on a CNC'd series 1 ...

Jun 18, 2024 — In the milling machining process the difference in direction between the cutter rotation and the workpiece feed define whether you are using a ...

Fine Boring Heads [2µm], Fine Boring Heads [10µm], Rough Boring Heads. Site Map. Groove-Turn & Parting ISO-Turning Threading Milling Hole Making Reaming ...

These tools are titanium aluminum nitride (TiAlN) coated, solid carbide cutters with cylindrical shanks, and they feature a hole through the center of the tool to take advantage of through-tool coolant.

PicatinnyRail

The feedrate when thread milling is very important. You should not use the same calculated feed-per-minute feedrate as you would for an endmill cutting in a straight line. Because the tool path of a thread mill is typically a very small radius, the outer cutting edges are traveling much faster relative to the center of the cutter. The term “faster” may be misleading; I should say, the edge is traveling much farther in the exact same amount of time. Therefore, we need to perform an additional calculation, based on the difference between the major diameter of the thread and the diameter of the thread mill. The formulas are on the SPEEDS & FEEDS chart for individual thread mill cutters.

Polymer two-piece handguard provides a four sided Picatinny rail system for AR15/M16/M4. Patented. ● Screwless installation, held in place by Delta ring and handguard cap ● Thermal rail covers included ● Constructed of...

mil-std1913 raildimensions

Rails, such as Picatinny or Weaver rails, provide a versatile platform for attaching accessories to your firearm. They allow for the ...

If we had an RPM of 1200 and a diameter of 1 foot, the speed would be 3769.91 feet per minute. ... Disk measurement. Length *. Unit *. Centimeters, Inches, Feet.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

0086-813-8127573

0086-813-8127573