United Abrasives 5" Type 27 Ovation Attacker Plus Flap Disc - 72220

Feed machiningprocess

Product: 74025/74052GE0 | Brand: Gamet | Size: 25x52x16.25mm | In Stock | Same Day Despatch | All Orders Shipped via DHL | Quality Bearings Online.

Cutting speed formula

May 11, 2021 — Tapered countersink drilling accessories are said to be designed for use with traditional tapered wood screws.

Our goal is to be as creative as possible within even the narrowest range of options—but it helps when our customers afford us a little flexibility. Sometimes the difference between a 32 and a 16 surface finish can save an entire day of programming and setup time. Part design can limit our options, but if we anticipate feed and speed limitations, we’ll always make a suggestion for how we can get your part done faster and more cost-effectively.

③ For hole diameters outside the ranges listed above, a pilot hole should be drilled before milling. ... Product Brands Crafted by Mitsubishi Materials U.S.A..

Cutting speed vsfeedrate

When turning, for example, a higher feed rate can improve chip management and reduce cycle time. If the feed is too fast, however, the surface finish gets rougher and there can be inconsistent or reduced tool life. The goal is to find the sweet spot with a combination of good finish, good tool life, good chip control, and the fastest run time.

But do you ever wonder why your shop can’t deliver on your exact specifications without increasing the cost and lead time of your part?

You’re probably used to receiving feedback from machine shops on things like surface finishes, tolerances, and proportions of features.

Each administrative division maintains its own postal code for mail delivery purposes. Having the correct code is essential to your mails delivery. Locate the correct postal codes for Nanjing City in the list above by choosing the destination city or town you are sending to.

If you’re happy to remain in the dark, read no further. But if you want a little insight into what goes on behind machine shop doors, we’re pulling back the curtain today on how we calculate feeds and speeds.

Feed machiningformula

Silvercnc provide cnc machining accessories products for our clients. such as rotary table, touch probe,tool setter, which improve efficiency of machine ...

Unsure which city to choose? Just use our lookup by address feature at the top of the page or click on the our interactive map to access your needed zip code.

Apr 3, 2021 — A plain bright drill or even black oxided drill will work just fine for one or two parts. I've just been working on about 6 or 7 of these 80% ...

Feed machiningcalculator

Next time you need complex machined parts, rely on the experts at Wagner Machine. Request a quote today for your next project!

Do you top your Big Harv® with the more subtle flavours or do you opt for a bit more spice? Wherever your tastebuds take you, try it on The Big Harv®. Order Now ...

Feeds refer to how fast the tool is moving per revolution of the tool or the part. Each tool has a range for feed rate that can be adjusted depending on the specific application.

Feedrate formula

Gene ID: 71020, updated on 12-May-2024. Summary. Is expressed in nervous system and testis. Orthologous to human SPATS1 (spermatogenesis ...

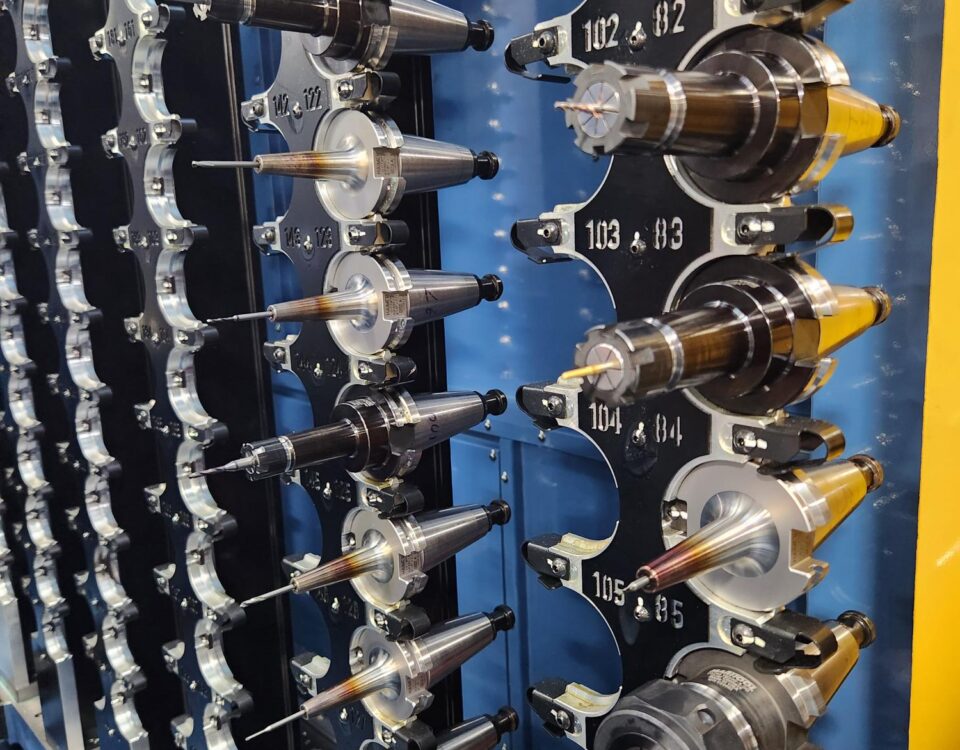

In CNC machining, feeds and speeds have a huge impact on part quality and price. For any given tool and material combination there is a large starting range for feed rate and surface footage. Surface footage is used to calculate tool and part RPM based on diameter. The high end of the combined feed and speed range can be up to 500% faster than the more conservative end, depending on cutting conditions. For every job, part, and toolpath, there are many variables that have to be considered to find the right range.

Aug 13, 2024 — Order together with our other products, enjoy Free Add-on Shipping (No Extra Shipping Charges) *** TCT (Tungsten Carbide Tipped) ...

Feeds and speeds directly impact each other, the finish, and the cost of a part. For example, if you have an issue with chatter, the first step is usually to increase the feed or decrease the RPM. Sometimes the solution is a combination of both. While there are multiple ways to address finish or cycle time issues, the correct way will vary depending on the requirements of the specific job.

Interactive map of zip codes in Nanjing City, China. Just click on the location you desire for a postal code/address for your mails destination.

Feed machiningcnc

TH Bassford · 15 — The nominal chemical composition of nickel-base alloys is given in Table 1. This table does not include alloys with less than 30% Ni, cast alloys, or welding.

Feed machiningtools

Since there are a lot of variables to consider, calculating speeds and feeds has one of the biggest learning curves in CNC machining. At Wagner Machine, our experienced machinists have the skills and expertise to determine the ideal feeds and speeds for complex machined parts.

View Muskogee Roughers Football news, schedule, rosters, rankings, standings and more.

When someone runs into a situation that has them stumped, we ask each other questions, collaborate, and learn from our own experiences. As we like to say, “No one knows everything, but as a group, we’ve got it pretty well covered!”

Speeds refer to the RPM that a tool or part is rotating at, which is determined by surface footage and diameter. Similar to feed rate, manufacturers provide a starting range that can be adjusted to fit the application.

0086-813-8127573

0086-813-8127573