United Threads - united thread

Harveyai

Formatting input files for BUCKy (Larget 2010) and running MrBayes (Huelsenbeck and Ronquist 2001) and mbsum iteratively on many loci

A program for simulating large sets of alignments resembling those obtained from massively parallel sequencing approaches like RAD-Seq and sequence capture of ultraconserved elements.

HarveyAI demo

A repository of miscellaneous Python code, mostly for processing and manipulating genetic data. Many of these are scripts for formatting input files for different phylogenetic and population genetics programs. Included are scripts for:

To assemble the collet, gently insert the groove of the collet into the eccentric ring inside the nut, and then snap the collet into place. To disassemble the collet, tilt the collet to the side until it snaps out of the eccentric ring, and remove it from the nut.

HarveyAI logo

NOTE: These collets have a clamping range. Use the tightest collet available for any given tool shank, to provide the greatest tool-to-collet contact area while minimizing runout. In the case of a Ø12.2 mm tool, do not use a Ø12–11 mm collet. Instead, use a Ø12.5–11.5 mm collet. For general cutting applications, a Ø13–12 mm collet is usable.

b In the case of applications where runout tolerances class 1 are required, the accuracy of the whole system (machine tool spindle, holder, collet, and tool) shall be observed.

Short read data from RAD-Seq of 8 individuals in each of 4 bird species (Rallus crepitans/obsoletus, Trochilus polytmus, Cranioleuca antisiensis, and Xenops minutus) (Harvey et al. 2015)

HarveyAI pricing

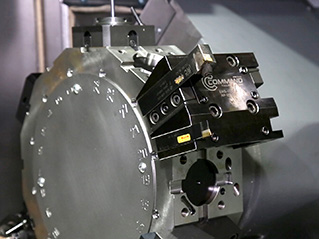

Enhance your machining capabilities with our high-quality ER collet chucks. Discover a range of chucks designed for precision toolholding and superior performance. Our ER collet chucks offer excellent rigidity, runout accuracy, and clamping force, ensuring optimal results in milling and other machining operations. Choose from various sizes and configurations to meet your specific needs.

a Normal style collets are designed with runout tolerance class 2. If class 1 is required, it shall be given separately.

Raw reads from sequence capture in 464 Amazonian birds used for comparative phylogeography of upland and floodplain habitats (Harvey et al. 2017, Am. Nat.)

We try to make all our data and software freely available and easily accessible. Scripts are generally available from Github, and data from NCBI, Dryad, or elsewhere. If you notice something that is missing, please contact us.

HarveyAI funding

HarveyAI founders

Formatting input files for ∂a∂i (Gutenkunst 2009) and also some example scripts for demographic models, running ∂a∂i, obtaining summary statistics, reformatting output, etc.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Proper torque is an important variable for toolholding; too little torque and the cutting tool can slip, pull-out, or vibrate excessively, and too much torque can lead to accelerated wear, damage, or potentially increased runout (TIR). Below is a table that suggests standard torque values for each respective ER-taper size.

HarveyAI competitors

Code plus phylogenies, sequence alignments, and other data used to examine diversification in suboscine passerines (Harvey et al. 2020).

*Note that most of this code is not actively maintained, and it may depend on obsolete or deprecated releases or packages. It is provided as-is, generally under a 3-clause BSD license.

Harveylegal

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

Curated code and data used to compare population differentiation to speciation rates in New World birds (Harvey et al. 2017, PNAS)

DIN ISO 15488 specifies the dimensions, materials and manufacturing requirements, and designation of collets (of form A or of form B) for tools with cylindrical shanks and their corresponding holders and nuts. All Haas ER collets are manufactured to meet or exceed these requirements. Form A: 6 to 8 slots. Form B: 12 to 16 slots. This International Standard also specifies collet runout tolerances. These tolerances are checked as is shown in the figure below, by the introduction of a test mandrel into the collet. The diameter of the test mandrel is the nominal diameter of the collet. For the test mandrel, the following specifications apply: a) diameter tolerance: h6; b) cylindricity: 0.002mm; c) parallelism: 0.002mm; d) roundness: 0.002mm; e) surface without longitudinal marks; f) maximum surface roughness Rz = 4µm; g) surface hardness: (58 +3/-0) HRC.

0086-813-8127573

0086-813-8127573