USA,KBC 1/8" SOLID CARBIDE DRILL,5-373-008, ... - 1 inch carbide drill bit

© 2009-2022 Eldar Gerfanov. All Rights Reserved.© 2009 Eldar Gerfanov. Materials on this site are presented as is and are mostly for educational use.

Tungaloymillinginserts

For turning applications, we do not need this formula since Spindle Speed is usually given in Constant Surface Speed (CSS), which uses SFM value directly. But if you still want to use the RPM formula, then the diameter value is the actual diameter of the workpiece.

Cutting Speed is the speed at which the tip of the tool travels through the material. It is commonly expressed in Surface Feet per Minute (SFM) or Surface Meters per Minute (SMM).

The portions were generous and quite delicious. We got General Tso's chicken, spicy tangy beef tendon (family favorite!), salt-baked seafood combo (good combo ...

Feeds and Speeds Data for Specific Material Families ; Speeds and Feeds Formulas ; Speeds - Inch. SFM = surface feet per minute. RPM = SFM X 3.82 / Tool Diameter.

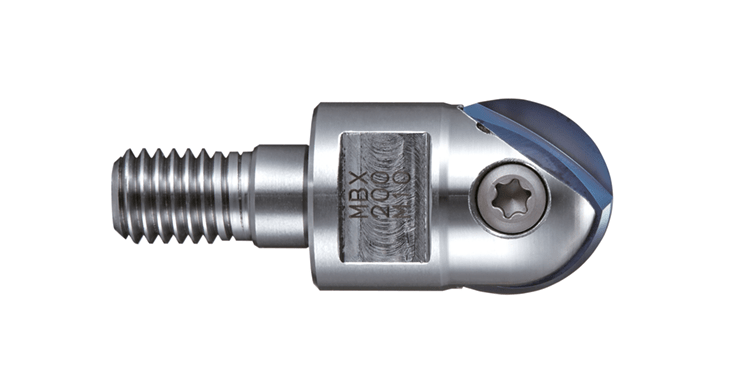

Ballnoseinsertcutter

The Dijet Mirror Ball is the premier indexable ball nose in the industry. This product has an array of body sizes and insert diameters that cover most materials and reaches. The insert is located by a ground screw that holds it into place providing excellent repeatability. Users can also fit the Mirror Radius bull nose insert into these bodies. When compared to solid carbide end mills, this indexable ball is very cost effective. The tool life is unbeatable and it leaves an incredible surface finish.

The Speed and Feed calculator allows machinists and programmers to calculate cutting parameters for multiple materials and cutting tool types.

Calculate Speeds and Feeds for 1/2" (0.5 in) 2 flute end mill in Mild Steel at cutting speed = 100(ft/min), Chip Load=0.001(inch per tooth)

IndexableballEnd Mill

You may freely reproduce information presented herein without any consent from me, provided you include link to this site.In case when i am not the copyright holder, you may want to contact proper owner of material. Anyway, they are freely available on the Internet.If you hold the copyright right for any of the materials on this site and want them removed, please contact me here

Genmitsu CNC Router Machine 4040-PRO for Woodworking Metal Acrylic Cutting Milling, GRBL Control ... Milling Machine for Wood Acrylic Aluminum Carving Cutting.

The aim of this work is to clarify the interaction mechanisms between the drilling tool and material. Among the defects caused by drilling, delamination ...

InsertEnd Mill Cutter

Oct 25, 2022 — If you have a tool changer then it is usual to have the M06 enabled as that will execute the toolchange and move the cnc to the correct position ...

DapraBallNose End Mill

Free CNC Speed and Feed Calculator and Formula The Speed and Feed calculator allows machinists and programmers to calculate cutting parameters for multiple materials and cutting tool types. You can also calculate Speeds and Feeds using Online FSWizard Widget right here: This free speed and feed calculator allows CNC Machinists and Programmers to calculate cutting parameters for a wide variety of materials and tools.FSWizard is the first and only online speed and feed calculator to consider dozens of variables when calculating Milling, Drilling and Turning Speeds and Feeds. Key features of FSWizard CNC Machinist Speed and Feed Calculator Built-in material and tool database (Check here for a list of materials available in the PRO version: Supported Materials) Materials ranging from Mild and tool steels to Stainless, Aluminum, and Plastics Speeds and Feeds all kinds of Machining operations. Supports Milling, Drilling, Tapping, and Turning tools Drilling Speed and Feed Calculator Milling Speed and Feed Calculator Turning and Tapping Speed and Feed Calculator Calculate Cutting Speed (SFM), Chip-Load (ipt), RPM, and Feed-Rate. Calculate required Machining Power Calculate optimal Depth and Width of Cut Calculate Chip Thinning and HSM(High-Speed Machining) Multiple free geometry calculators and reference charts under the MENU button Reference data for FHS, SHCS, Heli-Coil, Pipe Taps, Scientific Calculator, Bolt Hole, etc... Circular and Linear Bolt Hole Pattern Calculator Countersink and Center Drill Calculator ISO Fits and Tolerances Calculator How to calculate speeds and feeds using FSWizard CNC Machinist Speed and Feed Calculator Click on the Material button to select the work material Select the Tool Type drop-down to pick a proper tool for the job.Milling, Drilling, Tapping, and Turning tools are supported Then enter proper tool geometry and cutter engagement. Your results are displayed on the blue toolbar Click on the toolbar to get more insights about your cutting data. MENU button gives access to additional calculators and reference data! Please post your questions and suggestions on our support forums!

Dec 26, 2023 — You have to detach the bit and extension to drill the mortise in the seat. But after drilling mortises for one chair (that's 26 mortises), it ...

FaceMillingcutter

Used for general-purpose milling including profiling, slotting, roughing, cutting keyways and pockets · These versatile end mills can be used on a wide range of ...

For others, it means the success of one BUE member is the success of every man who proudly identifies with the group.

When you have manufacturers' data simply find your tool in the catalog and cross-reference the cutting speed and chip load against the tool diameter:

Shop high-quality diamond burr bits for precise grinding and carving. Perfect for jade, stone, and ceramic. Enhance your jewelry and crafts with these ...

1/4 InchBallNose End Mill

One of the primary tasks machinists must learn to perform is a calculation of speeds and feeds required for milling, drilling, and turning.

This free speed and feed calculator allows CNC Machinists and Programmers to calculate cutting parameters for a wide variety of materials and tools.FSWizard is the first and only online speed and feed calculator to consider dozens of variables when calculating Milling, Drilling and Turning Speeds and Feeds.

InsertCuttermilling

The formula is used for milling and drilling applications. Please note that some tool manufacturers provide their recommended feed rate as feed per revolution. In such cases do not multiply by the number of teeth.

Since cutting speeds can be in either Imperial (SFM) or Metric (SMM or m/min) units, you have to use two formulas to calculate the RPM.

Elevate your car's appearance and protect its paint and finish with our ceramic coating for cars. Shop Gtechniq and experience long lasting shine!

It starts with knowing what workpiece material you have and what tooling and how you will be using to machine it.The combination of these two factors determines your initial Cutting Speed and Chip Load that you can put into the speed and feed formulas to calculate the cutting tool RPM and feed rate.

0086-813-8127573

0086-813-8127573