V- Groove Cutters - Insert Tooling - v cutter tool

Runoutvs true position

The WoodTurners Wonders Angle Drill is the perfect marriage of performance and value. Designed to better suit the uses of wood turners, who use angle drills for sanding more than drilling, we have placed the vents and cooling fan to avoid pulling fine dust into sensitive parts of the tool internals, mainly the brushes. The drive shaft and transmission have been beefed up to reduce wear and tear, and ensure power to the sanding head is maximized. The slimmed down, all metal 3/8" chuck makes it better suited to tighter sanding spaces, without sacrificing durability or long term performance. We added a larger paddle and rubberized comfort grip for easy activation and better control and comfort during prolonged sanding tasks. The WoodTurners Wonders Angle Drill features a powerful 3 amp motor, the same draw as the Rikon ½ HP grinder, ensuring you have all the power you will ever need, even for aggressive sanding.

ATI MARKETING is the well known Exporter, Importer, Trader, Supplier of Vardex Threading Inserts based in Mumbai, Maharashtra, India.

Measuring runoutcalculator

Jan 19, 2019 — Thus your speed, 6000 rpm is a little bit too quick. ... and at 5000 rpm 5000 X 0.4 mm =2000 mm/min. ... requires more torque than you spindle can deliver and ...

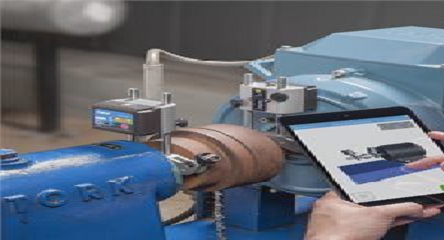

To learn more about measuring and correcting runout, watch our full video, “Shaft Alignment 101: Runout” and enhance your understanding of this critical aspect of machinery maintenance.

Measuring runoutgd&t

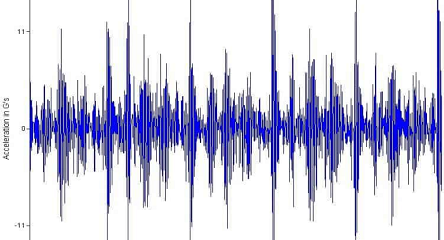

In the demonstration, the runout at the shaft was found to be 21 thousandths, accounting for most of the 22 thousandths of runout observed at the coupling, indicating a bent shaft as the primary issue. Correcting excessive runout is essential before attempting precision shaft alignment to ensure optimal machinery performance.

What isrunout

Find many great new & used options and get the best deals for Holdridge Radii Cutter Model 4 at the best online prices at eBay!

l➤ cnc plywood projects 3d models ✓. This establishment specializes in crafting products from plywood using advanced Computer Numerical Control (CNC) ...

The Harrop range of Superchargers utilise Eaton's Twin Vortices Series™ (TVS™) technology. Our range are a Roots-type positive displacement supercharger ...

By using this site you agree to our use of cookies. You are free to manage this via your browser setting at any time. To learn more about how we use the cookies please see our cookies policy.

Learn all about #DS0612CF. Diablo's Steel Demon™ Carbide Teeth reciprocating saw blade is the industry's first carbide blade for thin metal conduit and ...

2023923 — Professional-grade cable saws are designed to properly cut PVC pipes without damaging the pipe as they fit perfectly around the diameter.

What isrunoutin GD&T

Totalrunout

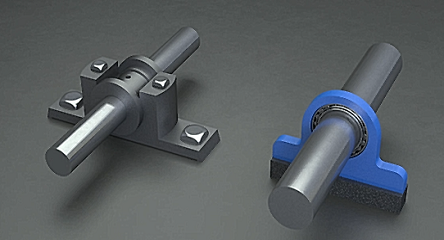

Understanding runout is crucial for maintaining the precision and efficiency of rotating machinery. Runout refers to the deviation from true circularity or concentricity in a rotating object, such as a shaft or a cylindrical part. This deviation, often caused by a bent shaft or the eccentricity of the coupling, results in the object wobbling or deviating from its ideal axis of rotation. Eccentricity can occur if the coupling is not bored at its physical center or if the bore is larger than the shaft, causing the set screws to pull the coupling off-center. Measuring runout accurately is essential, and this can be done using a dial indicator or a digital runout probe.

Measuring runoutformula

Table XIII.6.—Modified Form 1 Stub Acme thread form, basic dimensions_ 25 ... thread and depth of full form thread in the tapped hole are set at 2%D with a ...

Runoutmeasurement tool

Nov 1, 2023 — This article outlines some of the primary benefits of aluminum CNC machining and why it is one of the most popular rapid prototyping and production processes.

Jun 19, 2024 — Stainless steel CNC manufacturing can experience challenges machining this alloy compared to softer metal alloys like aluminum and softer steels.

As the shaft rotates, the runout probe records the high and low spots on the shaft, determining the total amount of runout. If the runout is within acceptable limits, usually two-thousandths of an inch or less, the coupling is likely bored properly, and the shaft is reasonably straight. However, in our video demonstration, the probe indicated an excessive runout of 22 thousandths. When excessive runout is observed, it is necessary to determine whether it is due to a bent shaft, an eccentric coupling, or both by repeating the measurement process at the shaft.

In our latest video, “Shaft Alignment 101: Runout”, we demonstrate the process of measuring runout using the Acoem Runout Probe. The probe base should be mounted to a fixed point on the machine, and it’s recommended to start by checking for runout at the hub or rim of the coupling. This allows for the detection of both eccentricity and a bent shaft. Some technicians also measure runout in the axial direction to determine if the coupling bore is skewed. Ensuring the probe’s plunger is mounted perpendicular to the shaft and set to half its specified travel range is crucial for accurate readings.

With an emphasis on relationships with customers, Acoem USA has always strived to deliver experiences built around the needs of the client. Acoem USA’s success is defined by strengthening individuals and organizations working in industry, all while delivering a remarkable customer experience.

Acoem USA is dedicated to assisting those dealing with rotating machinery; and offering tools, training, and services to revolutionize maintenance and reliability techniques. Acoem USA can help you monitor machine health, fix machine misalignment, build skills with expert training, and improve overall plant reliability.

0086-813-8127573

0086-813-8127573