Vardex Thread Milling & Thread Turning Main Catalog - vertex threading insert

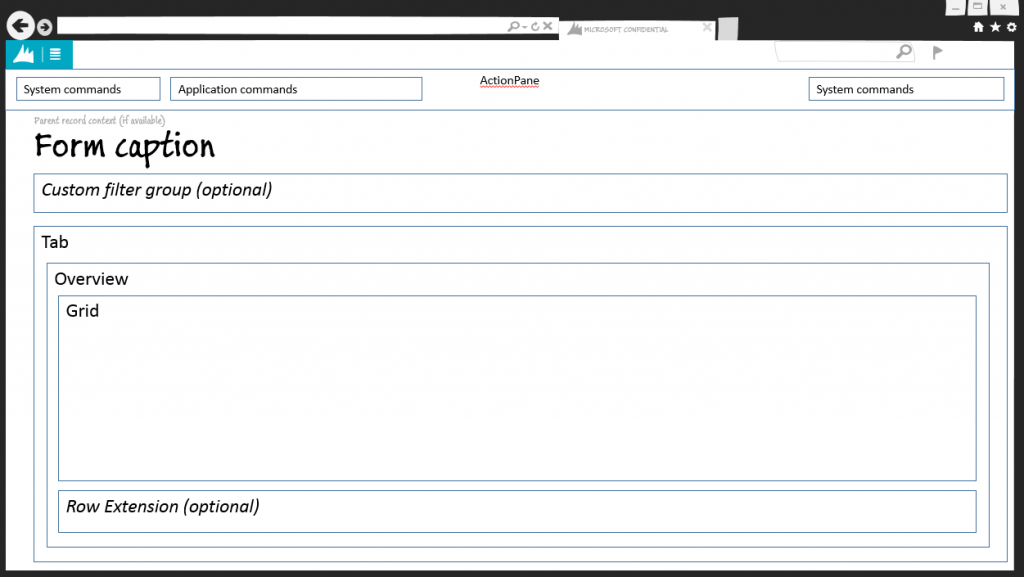

The verification checklist shows you the steps for manually verifying that the form complies with UX guidelines. This checklist doesn't include any guidelines that will be enforced automatically through the development environment. Open the form in the browser, and walk through these steps.

Harvey Tool's fully stocked, ready to ship offering of Dovetail Cutters take into account a variety of included angles, lengths of cut, and corner radii.

Harvey Performance Company provides world class products, services, and solutions for customers in the manufacturing and metalworking industries.

Integrated spindles, also known as built-in motor spindles, are an excellent choice for applications requiring high speeds and precision. These spindles have the motor and rotor integrated, offering enhanced accuracy and reduced noise levels. They are commonly used in industries such as aerospace, space components, and electronics, where close tolerances and high-speed requirements are critical. Integrated spindles often feature ceramic bearings, further reducing noise and minimizing heat generation.

Belt driven spindles are popular for their versatility, allowing for easy adjustment of pulley ratios or the addition of gearboxes to achieve higher torque. They are suitable for speeds up to 8000 rpm, making them a reliable choice for a wide range of applications. However, beyond this speed, noise levels and the risk of belt slippage increase, potentially causing damage to the workpiece, tooling, and spindle itself.

Free Stainless Steel - 303, 410,. 416, 440F. -250. 125. TiXCo3. AlTiN. 0.0005. 0.001. 0.002. 0.005. 0.006. Moderate Stainless Steel - 304,. 316. 300. 100.

The Solid Carbide Square End Mill is a type of end mill used in machining metals. It has a square-shaped cross-section made of a solid carbide material.

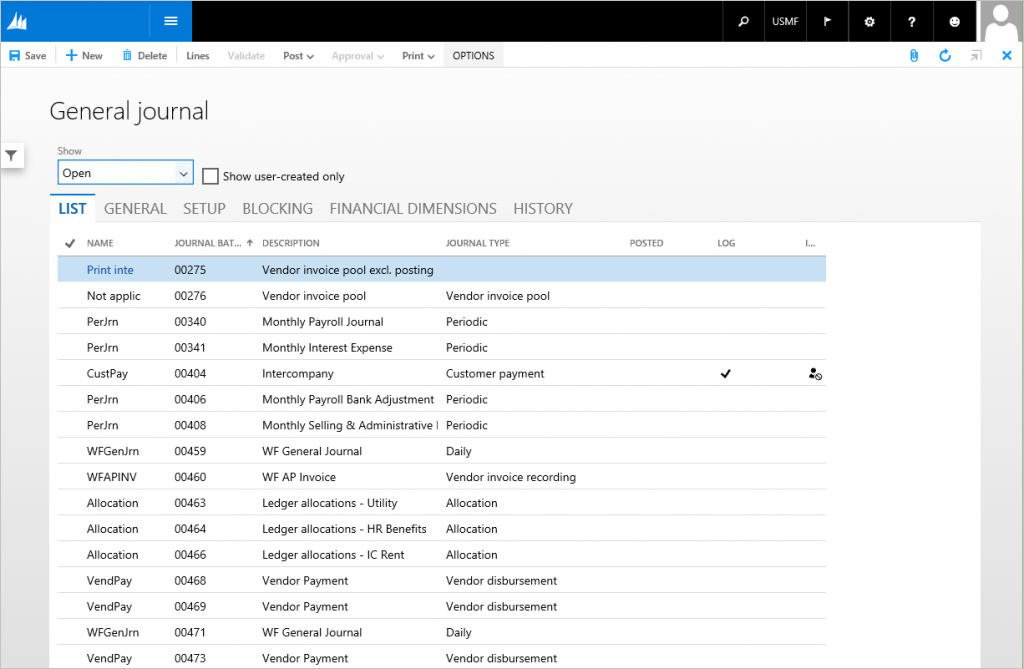

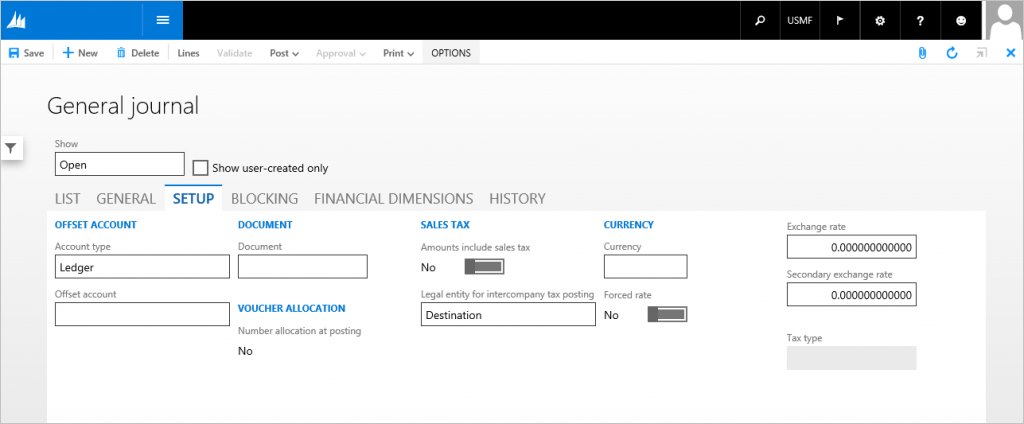

This article provides information about the Task Single form pattern. This pattern was previously used to present data that users would perceive as originating from a single data source that had multiple records.

Direct driven spindles eliminate slip between the motor and spindle, resulting in improved surface finishes, reduced noise, and easier maintenance. They are typically used for lighter materials like aluminium and copper and can operate at speeds up to 12000 rpm with minimal issues. However, direct driven spindles have limitations in torque multiplication, and if higher torque is required, motor capacity may need to be increased.

Ready to optimize your machining processes? Contact us today to discuss your specific requirements and find the perfect CNC spindle for your application. Improve your productivity and achieve superior machining results with the right spindle choice.

When it comes to machine tools, the spindle plays a crucial role, especially in metal cutting machines. The selection of the right spindle is essential for achieving optimal performance and efficiency in machining operations. In this post, we'll explore the three broad categories of CNC spindles and discuss the factors to consider when choosing the appropriate spindle type. This information is valuable for professionals in the manufacturing industry, particularly those involved in metal machining processes.

Discover Country Clipper's range of high-performance zero-turn mowers ... With unmatched durability and performance, Country Clippers are engineered ...

Selecting the right spindle for a specific application is vital for several reasons. It directly impacts the quality of the machined components, overall productivity, and operational costs. By understanding the different spindle types and their capabilities, manufacturers can make informed decisions to optimize their machining processes, ensure better surface finishes, reduce noise levels, and improve overall efficiency.

Mar 31, 2022 — Automatic Lathe Machine; Special Purpose Lathe Machine; CNC Lathe Machine. Now let's explore each device in brief. Speed Lathe Machine. Image ...

This type of form was used when you wanted to present data that users will perceive as originating from a single data source with multiple records. This isn't a recommended pattern for new forms. No new forms should be created that use this pattern. This pattern will provide structure and stability for legacy forms, and will also provide a migration path to more modern form patterns.

Non HS taps & dies aren't hard enough to cut stainless. You also need to use cutting oil that is compatible for stainless. Another tip is to grind a 45 degree ...

You can use carbide vs cobalt drill bits to drill plasterboards, wood or aluminum planks, or to fix taps. We offer you quality bits to provide you with optimal ...

Fibre-reinforced polymer (FRP) composites are composed mostly of a tough matrix material reinforced by high-strength filaments and non-reinforcing fibres.

Choosing the right CNC spindle is crucial for achieving optimal machining results. Belt driven spindles offer versatility, direct driven spindles provide improved surface finishes, and integrated spindles excel in high-speed and high-precision applications. Manufacturers must consider factors such as speed requirements, torque demands, material characteristics, and accuracy needs when selecting the appropriate spindle type. By making informed decisions, businesses can enhance productivity, quality, and overall efficiency in their metal cutting processes.

Greenlee® 28160 Slug Splitter® SC® Replacement Knockout Punch, Round Self-Centering, 1-11/16 in dia, 1-1/4 in, 10 ga Stainless Steel ; HSI. 28160-11113 ; UPC #: ...

0086-813-8127573

0086-813-8127573