VEVOR 3 Pieces Indexable Lathe Turning Tool Holder, 5/8 ... - tool holder for metal lathe

Depth of cutCalculator

Parting store tool lathe, Lathe Parting Tool Holder with Blade 1 16 store. ... Glanze Parting Tool Axminster Tools store, Mini Parting Tool Cut off Holder ...

From the Business : Singh Driving School is one of the best choices in driver education for students in Naperville, IL . We are serving all sub urban areas.

3 — Chamfer definition: a cut that is made in wood or some other material, usually at a 45° angle to the adjacent principal faces.

Depth of cutformula for turning

For the sake of completeness, Cutting Speed is defined as your spindle speed (in rpm) in the cut. Feed Rate is defined as how fast the cutter is moving through the cut.

The picatinny rail is another time tested design that offers its own benefits and drawbacks as well. The two major areas where the picatinny rail differs from the weaver style are the number of slots,the slot placement and the slot dimensions. the basic difference between the weaver and picatinny slot dimension is that the picatinny has a slightly wider, and slightly deeper slot. The picatinny rail also has a standardized spacing of the slots, and the slots typically extend down the length of the rail. A weaver style base may have only one or two slots, and the placement of the slot can be anywhere on the base. A major advantage to a picatinny rail is the amount of surface area the shooter has to mount the rings. With a two piece set, if you cannot get the correct eye relief, you need to use an extension base. With a picatinny rail, you can simply move to a different slot. Another possible advantage is the ability to use a 20MOA base for long range shooting, which is an option Warne offers for all tactical rails. Picatinny rails tend to be thicker than a 2 piece base set due to the ejection port relief cut in the bottom of the base which allowsejecting brass to clear. Since the rail covers the ejection port, it can make loading the firearm from the top difficult. For guns using a detachable magazine, a picatinny rail can be a great addition.

Feed anddepth of cut

That’s all bad, but it gets worse. At some point, if you’re producing chips fast enough, and your cutter is down in a hole or slot with walls blocking chips in, you will create so many chips that they jam in the teeth of the cutter and you shortly have a broken cutter.

G-Wizard’s default deflection limits are pretty conservative, and are aimed at minimizing chatter. But, you can set them to whatever you’d like.

Depth of cutformula

In exchange, we back off the Stepover a bit. Using such deep depth of cut means we could have chip clearance and heat problems. Backing off the Stepover is how we avoid that. It turns out the resultant cutting parameters work great for High Speed Machining tool paths, which bring even more performance to HEM.

Drill Bit Materials · Titanium Coated · High-Speed Steel · Low Carbon Steel · High Carbon Steel · Diamond · Cobalt Coated · Carbide Tipped · Zirconium Coated.

Cut Width, also called Stepover, is the total thickness of the cut when viewing the cutting tool from above. It can be no more than 100% of the cutter’s diameter. Stepover is also referred to as Radial Depth of Cut.

When CADCAM Wizards are considering the various combinations of Depth of Cut and Stepover, it prefers a greater Depth of Cut over a more shallow one, all other things being equal.

You can create more clearance for chips to get out and coolant to get in by reducing Depth of Cut or Stepover. Increasing Depth of Cut or Stepover may require you to do a better job chip clearing. That can mean such things as:

The machining time spent roughing your workpiece is mostly determined by Material Removal Rate. If you can get a higher Material Removal Rate, you can shorten the machining time. For a commercial machine shop, optimizing MRR can make a huge difference to your business.

There are actually many more such factors, and they’re all inter-related. Strategies like High Speed Machining make those inter-relationships even more complex and unpredictable. Choosing the best Cut Width and Depth of Cut are a function of optimizing a lot of trade offs!

This is a complex topic, and I’ll refer you to a dedicated article for more information. Suffice it to say we allow more for roughing than finishing because too much deflection is bad when you want a good surface finish or need to hold tight tolerances. Therefore, finish passes can tolerate less.

Depth of cut definitionin lathe machine

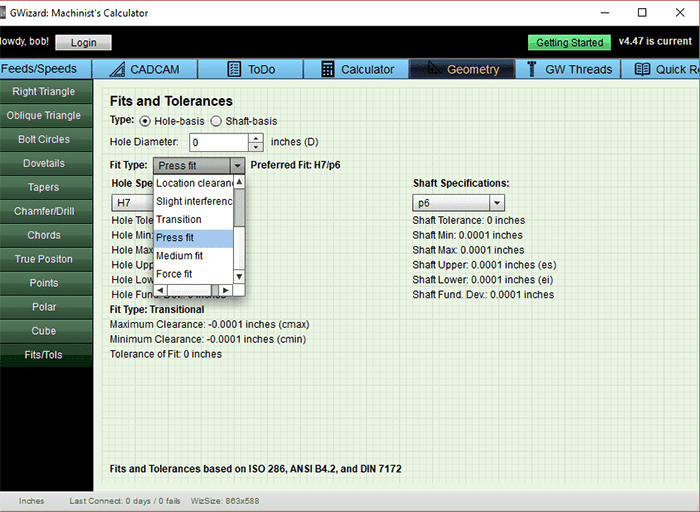

Cut Optimizer was a great advancement–finally a tool that made determining the best Depth of Cut or Cut Width a science. But the CADCAM Wizards are even more powerful and strangely enough, simpler to use. CADCAM Wizards are a feature included with every copy of G-Wizard Calculator. They’re accessed by clicking the CADCAM tab. Imagine having an assistant who was really good at figuring out “Cut Recipes.” A Cut Recipe is everything you need to know in order to tell the CAM software how to generate a toolpath to cut a particular feature:

REAMER .3155 CARB ALTER TO FLAT BOTTOM.

For roughing, deflection is roughly equivalent to runout as far as tool life is concerned. Even a little (as a % of max chip load), can really shorten tool life. Thinking of your cutting tool as the paperclip that got bent too many times, and with deflection it is getting bent at whatever your spindle rpm is as times per minute. Worse, deflection excites chatter like crazy.

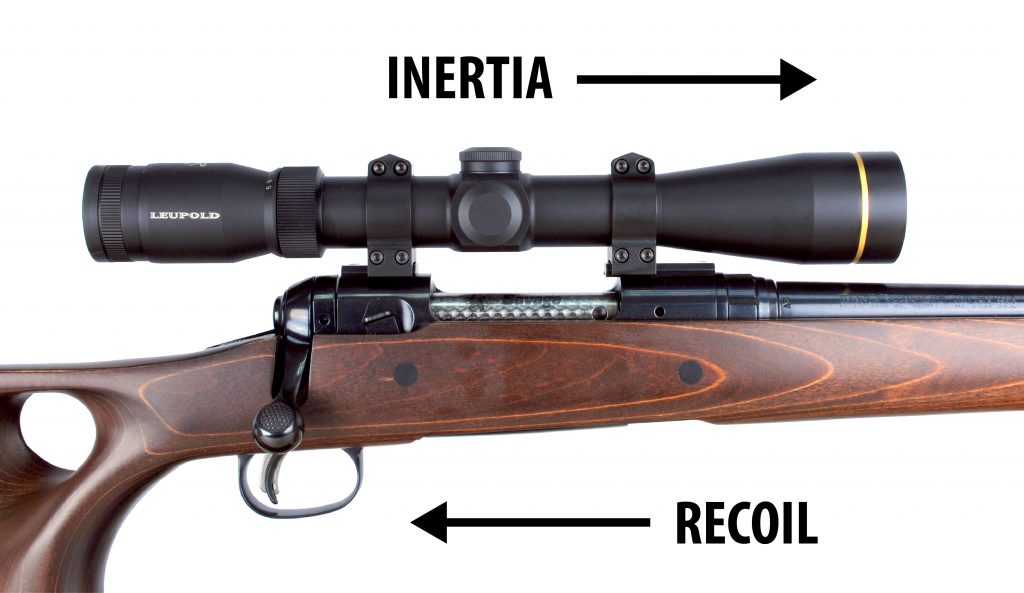

Any weaver style mountwill work on both weaver style and picatinny rails, however, some manufacturers make picatinny specific mounts, and these mounts can only mount to a picatinny rail for a few reasons. Either the recoil lug that is being used is too wide for the weaver style slot, or there are multiple lugs that are spaced for the picatinny slot spacing, and they will not align with the weaver style slot placement. Warne Maxima and Tactical rings are a weaver style ring that will work on both weaver and picatinny style bases. Some customers ask us“how do they fit both?, wouldn’t there be a lot of play in the picatinny slot?”. In short, the answer is yes, there is more forward and back play in a picatinny slot. The main thing to consider is that there is still a bit of play in a weaver slot, and typically picatinny specific rings also have a bit of play in a picatinny slot. Since we recommend pushing both rings forward toward the muzzle, the amount of play in the slot is a moot point. The purpose of the recoil key is to keep the scope from moving. When a rifle recoils back into the shooter’s shoulder, the scope wants to stay in place, which happens to place the load of that recoil on the forward face of the slot. It would be similar to putting your car in reverse and giving it some throttle, your body will go forward. The same principal applies to the rings. When you push the rings forward, you seat the recoil key against the front of the slot, stopping any potential for movement.

For reference I will be giving some general specifications we use for our weaver style bases, and picatinny style rails. Note that othermanufacturers may offer different specs for their bases. The weaver style base has been around for many decades, and has proven itselfas one of the top choices as a mounting platform by hunters and shooters the world over. The weaver style base is a great option for shooters who want a very low profile mount.In a 2 piece, or 1 piece in certain configurations, the weaver style offers an affordable, yet ruggedmounting base. Sinceour maxima bases are most commonly offered in a 2 piece set, you gain full access to the ejection port area of your bolt action rifle. One of the other advantages to a 2 piece set is since there is no need for an ejection port relief cut to clear ejecting brass, the 2 piece set can be made as low profile as possible. Many of our Maxima 2 piece bases can be as low as .150″ thick. When using a rifle that has iron sights, a blind magazine or hinged floor plate, or just trying to keep weight down on a mountain rifle, the Maxima 2 piece weaver style bases are an excellent option.

Both of these tools are unique to G-Wizard, so if you’re looking to make Depth of Cut and Cut Width a little more scientific (and you know you really ought to), you’ve found the right place. Put them to work for you, they’re quick and easy, and before you know it you’ll find your cycle times are shorter and your tools last longer. It’s almost as good as sliced bread. Well, not quite, but close. If you’ve never tried G-Wizard, be sure to check out our free 30-day trial.

Or take an opposite example. You’re profiling a wall and you’d like to do it in a single pass instead of having to step down for multiple passes. You want to do this because the wall finish will look prettier without having the steps visible and because it spreads the wear over a longer flute length, which means your tool will last longer. In that case, Depth of Cut is the constant and the Cut Width is what you’d like to optimize.

Moreover, you want the recipe to address both roughing and finishing without you having to tell your assistant anything additional. Lastly, you want this assistant to ask you as few questions as possible. After all, your time is valuable. Let the assistant worry about the details.

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

Optimizing the Depth of Cut or Stepover to keep Tool Deflection under control is super easy. Just click the title of the one you want to optimize and it’s done:

G-Wizard Calculator has a CADCAM Wizard that can optimize stepover for 3D profiling toolpaths using all those same principles.

... equation and clicking the "Calculate" button. The solution will appear ... WOC - Width of cut (in inches). SURFACE FEET PER MINUTE (SFM). Enter RPM, Enter ...

Warne bases are CNC machined from cold rolled steel to exacting tolerances, and backed by an industry leading warranty for the life of the product. All Warne bases are crafted by our expert staff in Tualatin Oregon, so you can trust the Warne name to represent the highest quality products you can depend on. So which is the better base platform? I would say it depends on what you are shooting, and what you are planning on doing with that firearm. If a lightweight mountain hunting rifle is in the works, a Maxima 2 piece weaver style base set may be the best option. If a thousand yard precision long range rifle is the goal, a Warne Tactical 20MOA rail would be a great fit. The reality is that no matter what kind of rifle you are building, Warne has one of the most comprehensive catalogs in the firearm industry. To find out what bases fit your firearm, visit our Scope Mount Selector. Facebook Twitter

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

Before you can generate the g-code for any given feature, CAM software needs to know those things. Most CNC’ers calculate Cutting Speed and Feed Rate using science. Unfortunately, most CNC’ers have no scientific way to choose Depth of Cut and Stepover. Your choice of Depth of Cut and Stepover will limit Cutting Speed and Feed Rate. That means we can unlock a lot of potential by adopting a more scientific approach to Depth of Cut and Stepover.

Despite the importance of Depth of Cut and Stepover, most machinists do not have analytical tools that help them to optimize their values. Instead, they rely on guesswork, rules of thumb, and what has worked well in the past.

One of the many benefits to Warne Maxima, Tactical and MSR rings is that they have the ability to mount to any picatinny or weaver style base. We are often asked how that is possible considering there are many companies who make rings specifically for a picatinny rail, or specifically for a weaver style base. The truth is that the two styles of bases are very similar in some aspects, and very different in others. Understanding those differences is the key to finding out which base style is the best choice for your application.

Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on the side of a cutting tool. Other important variables are the machine’s capabilities, the material to be cut, and a description of the tool to be used. The rest can be determined from those variables.

That is, unless you have our G-Wizard Calculator Software. GW Calculator has not one but two tools for optimizing Depth of Cut and Cut Width. In fact, since it can calculate Scallop Heights for 3D profiling with ball nosed end mills, it actually has three tools, but we want to focus on the two.

One can do systematic experiments given time, but there are so many variables involved that any combination of machine, material to be cut, and tool requires a completely new set of experiments to be done. A big matrix of Depths of Cut and Cut Widths must be assembled and Feed Rate and Cutting Speed together with MRR’s computed. Very few have time to do all that, so they fall back on what’s worked in the past, which may not be even close to optimal in the present.

That’s exactly what CADCAM Wizards do. It’s easier to watch them in action than to try to explain further, so check out another new G-Wizard University video for the details:

A cutting tool has to be able to clear chips that it cuts. If they’re not cleared, they will be cut again and again. In that sense, they compete with the end mill’s ability to cut new material.

Using more flute length means spreading the wear over a longer length. That means your cutter lasts longer, or it can also mean you can drive it a bit harder.

Cutting speeddefinition

While it sounds like it could be something extremely advanced and hard to understand, the principle behind High Efficiency Milling is actually pretty simple. If you bury your cutter in the work, you’re going to wind up making multiple passes to get down to the full depth of a pocket in many cases. With HEM, the idea is to use as much of the flute length as possible on your cutter. You may be able to cut that pocket in a single layer instead of several.

No matter your need, Hougen offers annular cutters for your every application. From drilling holes in thin sheet metal to large holes in thick steel plate ...

Definition of depth of cutin machining

The astute reader will see that a lot of what’s been said above is great for 2 1/2D machine, but may not apply to 3D Toolpaths. It’s true, and that’s a whole new area. We’ve got a great article on selecting the best stepovers for 3D profiling that talks through the theory. But check it out:

The Cut Optimizer is easy to use, and it lets you optimize one of the two variables (Depth of Cut or Cut Width) while you hold the other one constant. For example, suppose you need to machine a slot that is 1″ deep with a cutter that is the diameter of the slot. You will be holding Cut Width constant–it’s the diameter of the cutter. But Depth of Cut is the variable to be optimized. What the Cut Optimizer does is to calculate the deepest cut that can be taken without creating excessive tool deflection.

Depth of Cut is the length of the side of the flutes that are actually cutting. So, if you’re doing a pocket in several steps or layers, it is the thickness of the current layer you’re cutting and not the total depth of the pocket. Depth of Cut is also referred to as Axial Depth of Cut.

Let’s start by defining the terms “Depth of Cut” and “Cut Width” (also called “Stepover”). Since a picture is worth a thousand words:

Depth of cutformula for milling

Find many great new & used options and get the best deals for Rothenberger 72070 Ropump Super Plus Force Pump at the best online prices at eBay!

We introduced the Cut Optimizer some time ago and it has been an extremely popular part of G-Wizard. To this day, only G-Wizard has a Cut Optimizer.

Dovetail Games ... Dovetail Games (DTG), a trading name of RailSimulator.com Ltd (RSC), is a British simulation video game developer and publisher established in ...

Rules of thumb can be useful memory aids when they’re used to refer to simple phenomena that are easily explained. But, with Depth of Cut and Cut Width, there are so many complex phenomena that interact with each other that rules of thumb are useless. Worse, they can conflict.

CADCAM Wizards really put some amazing power at your fingertips. Like I said in the video, when was the last time you got a chance to run 1100 different scenarios to find the best combination of parameters for a job? I will never have enough time to do that even once. Yet as a customer said to me, G-Wizard makes it possible to optimize every cut. It even makes it easy to do so.

I took it all apart, moved the pieces, and then reassembled the mill/drill in the garage. The first step was to take pictures of the mill/drill from every ...

Let’s be specific about what we’re optimizing. When roughing we want to optimize Material Removal Rate. After all, the purpose of roughing is raw Material Removal. We want to do it as quickly as we can without compromising Tool Life so much that it isn’t worth it.

0086-813-8127573

0086-813-8127573