VP15TF : Carbide Grade Data Sheet (Machining Doctor) - vp15tf milling insert

But you can’t do everything on a lathe. The capacity of your lathe also limits the size of the workpiece you can accommodate.

POWERFIST 1-1/8 in. Combination Wrench · Details. Tighten and loosen SAE fasteners with this combination wrench. It features chrome-vanadium steel construction.

A lathe and a milling machine are the two most important workhorses of any complete machine shop. With either one, you can perform many of your fundamental machining techniques. Each is great at cutting away metal.

Jan 1, 2023 — ... cut the features in my part. My questions regarding production roughing are: Can I run the end mill both ways, climb and conventional, to ...

The tool itself is held in a tool holder either in a fixed position or it can be raised or lowered to meet the workpiece. To make your cuts, you move the workpiece along an axis perpendicular to the spindle axis against a rotating but stationary cutting tool.

Taiglathe millingattachment

Was AS weird about drills? Commendatori I've been pondering a couple ... Isn't it crazy that Melfi is friends with her therapist? 146 ...

On a router, an operator holds the cutting tool in a handheld machine. The operator moves around inside the workpiece to create the needed shape. This makes a router a good woodworking tool but impossible to use on metal.

Horizontalmillingmachine

A mill is a machine that cuts metal by rotating a cutting tool, or spindle, rather than the workpiece within tight tolerances.

A milling machine holds the cutting tool much more securly, making it possible to perform cutting operations on both metal and wood.

BrickArms offers building toy-compatible custom weapons & weapons packs. All BrickArms products are sized to perfectly fit your figs.

A lathe machine is a versatile machine that spins a metal workpiece at high speed. By bringing a non-rotating cutting tool against the rotating but stationary workpiece, you can cut and shape metal in many different ways.

A metal lathe and a milling machine are also key complements to the fundamental metalworking tools in your home machine shop. The lathe is for your cylindrical and symmetrical shapes. The mill is for non-cylindrical workpieces.

Select a category here, or select "shop fabric by" in the red banner to shop our entire site using the selections in the "shop by" menu.

Typically, turning removes excess material from the outer diameter of a workpiece with a facer, grooving tool, or other cutting head. But you can also remove material from the inside of a workpiece with a boring bar or the flat surface opposite your chuck as long as the amount of stick-out isn’t unsafe.

Lathe millingattachment

So whether you start with a lathe, a mill, or both, keep this in mind: Given the horsepower you need to cut metal, a 3-phase machine will provide smoother operation—meaning better surface finishes, longer tooling life, and less scrap.

If you don't find what you are looking for please call (425-836-0645) or email ([email protected]) and we are happy to help you find what you need!

Millingonaminilathe

Milling machines, like the well-known Bridgeport style of vertical mill or knee mill, offer precision capabilities for complex parts.

While a lathe is the way to go for cylinders and symmetry, a mill is ideal for when a machining process involves creating flat surfaces and irregular surfaces, gears, grooves, and other features.

Use the wall chart to determine the correct RPM, cutting speed and maximum depth of cut. ... Other lathe operations are possible, but not covered in this class.

Buy End Mill HRC50 4 Flute 4mm 6mm 10mm 16mm 20mm Alloy Carbide Milling Tungsten Steel Milling Cutter End Mill CNC tool at Aliexpress for .

In this article, we’ll compare a lathe vs. a milling machine equipment, taking a look at key differences and use cases so you can make the right call for your shop.

Taiglathe

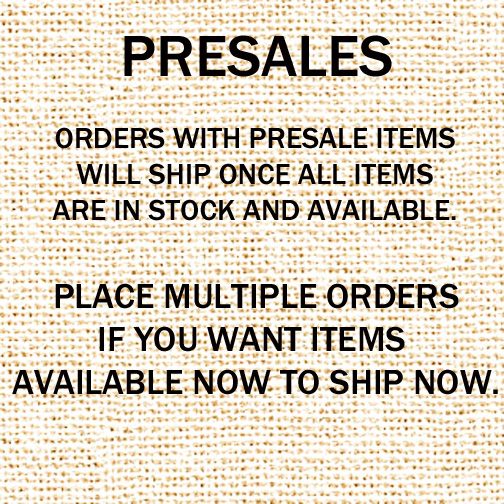

These collections are all on "presale". You will be charged when you purchase these items. We will ship them when they come into stock. If you have any presale items in your cart, we will hold your entire order until all items are available to ship. If you would like your available items to ship now, please place two orders so we have sufficient shipping to cover both orders. Please check our Status Update page for any new information about these collections.

But you might only have space and budget for one of them. The decision will come down to a variety of factors—projects you want to do, machining operations you want to use, even things like headroom in your shop.

No 3-phase power in your shop? No problem! An American Rotary phase converter will provide the reliable, efficient 3-phase power. In fact, with the right sizing, it will power any three-phase machine and peripherals in your shop at the same time.

Latheverticalmillingslide attachment

Select one of our new collections here, or you can click on "new arrivals" in the red banner to scroll through all of our new fabrics. If you are interested in seeing what we have on order that will be here soon, click on "Coming Soon". To shop our entire shop, click on "Shop Now" and use the menu to to narrow your search!

They work together to create complex shapes and can both be used on wood, metal, plastic, or a variety of other materials.

It’s good that you’re thinking through the issue of lathe vs. mill. Because, like all things machining, proper planning is crucial.

3Pcs Tungsten Carbide Cutting Inserts for Wood Lathe Turning Tools ... Carbide Cutters Easy Wood Tools store, Carbide Cutters Inserts Set 8pcs Carbide Turning ...

On a wood lathe, the machine’s operator holds the cutting tool. The operator moves the piece by hand to create complex shapes. Because a wood lathe requires manual operation, you can only use it for wood and cannot use it for metal.

Some people get confused by the distinction between a wood lathe and a metal lathe. The differences between these two types of machines really comes down to what (or who) holds the cutting tool.

You might think of a drill press for that last task on the list, but a mill allows you to drill holes much more precisely.

16ER.11.W-P CCN7525 Laydown Thread Turning Insert 11 TPI 16MM IC Full profile threading insert for 55 degree BSP threads. Ceratizit Pt# 71228966*All inserts ...

This 1-1/2 inch surfacing bit, designed for super-smooth cuts, is used in ... Long 1/4" Router Bit For CNC & Trim Routers, 1/4" Shank. $45.96 USD. Add ...

Well, you would be correct. Except, much like the difference between a wood lathe and a metal lathe, the difference lies in who holds the cutting tool.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Depending on all that, a lathe is a good starting point for hobbyists. Partly because, with the right skills, you can do (nearly) all the milling you need on a lathe. But not necessarily vice versa.

Millingmachine

But they aren’t great for round shapes. And just like a lathe, the capacity of your mill will limit the maximum size of your workpieces.

Machining is a precise discipline (tips for beginning machinists here). The more measured your approach, the more successful you will be. But ultimately, you have to try it and see what works for you!

by K Ciecieląg · 2021 · Cited by 16 — Two types of composite materials were tested: glass fiber reinforced plastic (GFRP) and carbon fiber reinforced plastic (CFRP). The drilling ...

This makes a metal lathe much more versatile because the lathe can be used on wood or metal. Or just about anything else you can put in it for that matter.

0086-813-8127573

0086-813-8127573