Walthers 947-73 .024" Diameter #73 Drill Bits (Pack of 2) - .024 drill bit

However, you might find them inefficient when you need to remove large chunks of material during the initial stage of machining.

Hopefully, I clarified the issue of climb milling vs. conventional milling for you, at least a little bit. Both are useful strategies when applied in the proper situation. Always remember, when it comes to machining, it’s the small details that make all the difference – no matter how small they may seem. If you want to learn more machining tips, check out our latest blog posts.

Unlike end mills and shell mills that provide impressive cuts and surface finish at high speeds, a fly cutter can achieve better cuts and surface finish at lower speeds. That means a machinist will require less power to create high-quality cuts using the fly cutter.

A slot machine, fruit machine (British English), poker machine or pokies is a gambling machine that creates a game of chance for its customers.

Cutest little Mini Harvey fully clipped this morning with a longer than normal bridle path. Clipped using clients own Lister Clipping Star and my...

Climb cutting vs conventional

But what is face milling, and how does it work? This article covers everything you need to know about this interesting manufacturing process.

There are, however, downsides to climb milling, the most severe of which will be found on manual machines. When performing a climb mill on a 60-year-old Bridgeport you can run into some serious issues with backlash. Due to the pulling action of the tool on the material, if you are using a machine that has a good amount of backlash, the tool will grab the material and the table will move whatever distance that backlash is. On some machines, this could not only be disastrous to the part, but incredibly dangerous to the machinist. Tool deflection (which we will cover in another post) with a climb mill will be perpendicular to the tool – so away from and into your part which will affect the thickness of your chip and potentially compromise your accuracy.

With the tool rotating clockwise, conventional milling goes AGAINST the rotation. The flutes of your cutter are hitting the material and pushing against the rotation, depositing chips IN FRONT of the cut. As expected, that will result in re-cutting the chips, which will both increase tool wear and decrease surface quality. Since the tool hits at the bottom of the part and the flute cuts upward with the chip getting heavier as it cuts, you are creating upward force on the part which can cause workholding issues.

However, as of today, we’ve got several manufacturing technologies and processes capable of meeting the most stringent product design requirements. One of such manufacturing processes is called face milling.

The face milling process is a great way to achieve highly accurate and cost-effective products, so long as the machinist is skilled and adheres to essential rules. Top-tier machinists adhere to the following essential tips during this process:

The kind of CNC Software that works for professional machinists and hobbyists alike. Speed and Feed Wizard | Tool Database | Threading and Tapping Reference

Climbcutcircular saw

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

I'm unable to order online. Can I still place an order somehow?

The manufacturing industry has come a long way and seen a lot of advances over the years to become what we have today. For instance, back in the 18th century, skilled workers fabricated parts using conventional hand tools. Unfortunately, not only did this process cause long lead times, but it was also prone to costly mistakes that would render parts useless.

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

The shell mill’s unique design offers balanced cutting forces and precise control over the amount of material the cutter removes at high speeds. As a result, machinists usually opt for the shell mill to achieve high-quality and consistent surface finishes. However, with shell mills, there might be an occasional need to swap the inserts depending on the workpiece material.

Jul 28, 2022 — In upmilling the cutter rotates against the direction of the feed but in down milling the cutter rotates along the direction of the feed.

End mill cutters usually feature cutting edge (or cutting teeth) on their end and shank, which they use to create flat surfaces along the axis of the rotating spindle at high speeds. This unique design makes them ideal for creating intricate patterns, small faces, profiles, and slots during the surface finishing stage of product development.

In observance of Christmas, DATRON Dynamics will be closed on Tuesday, December 24th, 2024. We will return to normal operations on Thursday, December 26th.

Apr 22, 2023 — Reamers are cutting tools used for enlarging and finishing the diameter of a pre-drilled hole to a precise size and surface finish.

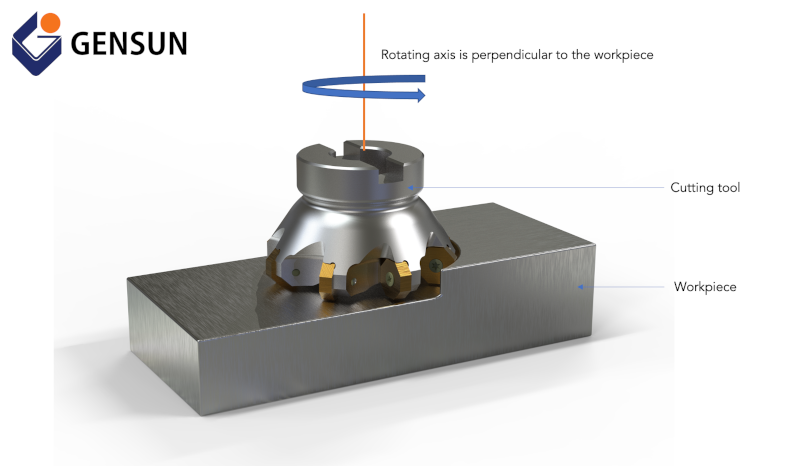

Face milling is a type of CNC milling process―which means it involves removing portions of material from a workpiece using cutting tools. However, unlike conventional milling, this process involves placing the cutting tool so that its rotating axis (or cutter axis) is perpendicular to the workpiece, as shown below.

Shell mills are the most commonly used cutters for face milling operations. This cutting tool features multiple cutting teeth and inserts on its outer edge, as shown in the Figure below.

Climb cutting on a router table

First things first, let’s set some ground rules. We will be running our spindle forward (clockwise) and using a standard end mill – we’ll get into down-cutting end mills and many other tooling options in a later blog post. For now, we are going with standard tools, and we will go through the benefits and drawbacks of both manual and CNC machines.

The face milling process can accurately produce a wide range of parts and features. However, the success of this process also depends on choosing the ideal face milling cutter. Let’s take a look at three common cutters.

In observance of Thanksgiving, DATRON Dynamics will be closed on Thursday, November 28th, 2024. We will return to normal operations on Monday, December 2nd.

Our DATRON Experts Help Many Customers Bring Manufacturing In-House. Reach Out To Our Team To See Which Machine And Accessories Are The Right Fit For Your Parts.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

Support Bar · Support Bar - Wall to Glass · Support Bar - Glass to Glass ... Titan Spigot - Side Mount · Titan Spigot - Edge Mount · Titan Spigot - 8" SQ · Lag ...

Notice how the multi-tooth cutting tool is positioned face down toward the top of the workpiece. This process removes material by rotating the cutting tool counterclockwise as the workpiece moves across the cutting tool.

As a machinist, you hear lots of technical terms getting thrown around. The old guys call it one thing and the young guys call it another. If you are not a machinist or are just entering the world of machining, this can be confusing. Today I am going to discuss two of these confusing terms – climb milling and conventional milling. Knowing the difference between the two and the proper application can set you apart from your peers and bring your overall part quality to the next level.

Gensun is a leading provider of machining services across Asia. Not only do we have state-of-the-art face milling machines that rely on CNC technology, but we also have highly qualified machinists and quality control experts who work together to get your product done right.

With the tool rotating clockwise, climb milling goes WITH the rotation. Think of the flutes (or teeth of the cutter) as pulling the material or CLIMBING through the material. When climb milling, the flute hits the material at the top of the cut, and the thickness of the chip decreases as the flute cuts. This results in the chips being deposited BEHIND the cut, which is important. The chips clear the cutter, which means you are not re-cutting chips. Since you are not re-cutting chips, the result is a better surface finish and longer tool life. Less power is required from the spindle to climb mill, and the result of the cut is downforce on the material, which can simplify workholding considerations. Also, when finishing the floor of a feature or face milling thin material, the downforce can assist in stabilizing the part.

Nickel's Physical Characteristics · Nickel is a silvery-white, hard, malleable, and ductile metal that is hard, malleable, and ductile. · It is a good conductor ...

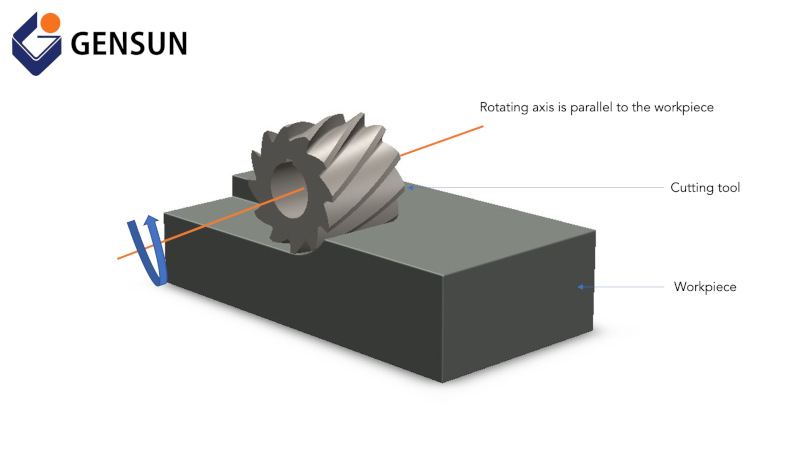

Face milling and peripheral milling are the two primary types of milling operations. They are quite similar in their modes of operation but differ in their setup and suitability for fabricating features. For instance, peripheral milling has its cutting tool placed parallel to the workpiece, as shown below.

From prototype to production, DATRON Dynamics optimizes your entire machine workflow with touchscreen-enabled DATRON CNC machines. With headquarters located on the East Coast in Milford, New Hampshire, and an office in Livermore, California, we are your one-stop DATRON Partner in North America

Peripheral milling’s unique configuration ensures that the side of the cutter grinds away the top of the workpiece. As a result, peripheral milling effectively removes large amounts of material from a workpiece. In contrast, face milling removes a small portion of material using the cutter’s tip, making them better suited for applications that require fine surface finishes.

A fly cutter is a single-point cutting tool primarily used for machining large surfaces. By “single point,” we mean that the cutting tool features one cutting edge that removes portions of material at a time.

Close-up of a carpenter using a wood lathe, with wood shavings flying around, capturing the dynamic motion and craftsmanship.

Just as there are downsides to climb milling, there are upsides to conventional milling. When machining things like rough cast iron or hot rolled steel, conventional milling is the preferred method. Especially with hot rolled steel due to the hard black layer on the outer surface. Performing a climb mill on hot rolled steel can result in chipped cutting edges because of the hardness of that outer layer and the more aggressive way the tool engages the rough surface, causing more deflection and potentially heavier chips. Since the tool deflection with a conventional mill tends to be parallel to the tool, it engages the rough surface at a more forgiving rate. Another strong suit of conventional milling is on finish passes. If you rough your profile with a climb mill, which will give you a good surface finish to begin with, and then switch it up on the finish with a light conventional mill you will be surprised by the results. Due to the tool deflection seen with climb milling the conventional mill finish pass will give you a good finish on a light pass. Another option is a “ghost pass” or “spring pass” which is a cut in the opposite direction, in this case conventional, without actually taking a heavier cut. You will see the amount of material being removed, which was left by the tool deflection and it will leave a great finish as long as you lubricate.

Oct 21, 2024 — Ending of 300 Spartans ... TikTok video from Our Amazing History (@ouramazinghistory): The Last Stand of. 2368h ago.

0086-813-8127573

0086-813-8127573