We Can Recycle Your Carbon Fiber - can carbon fiber be recycled

The Latest INDEX to Model Engineers’ Workshop Mach3 problem? Thread pitch of screws used on Stihl equipment EN8M FLAT Strange drilling situation Creworks Lathes on Amazon UK – some big price drops for Black Friday Week What is (Traditional) Model Engineering? FreeCAD version 1.0 released modifying Schaublin collets A blast from the past

![]()

Standard reamer sizesmetric

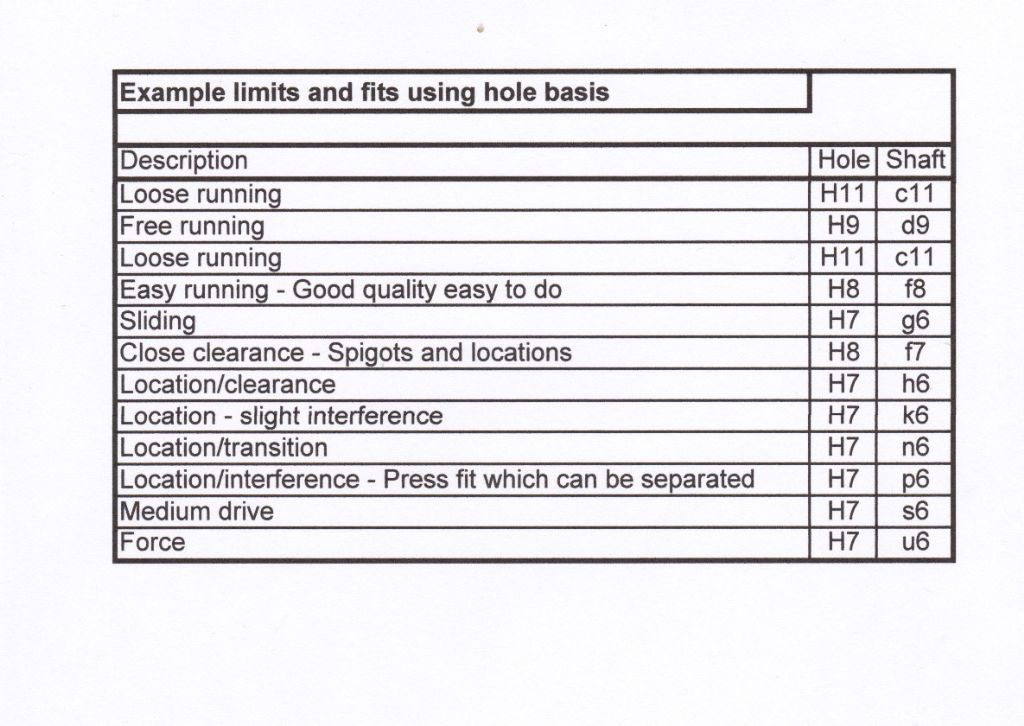

It shows that we should be able to achieve the tolerances by grinding, broaching, reaming, boring or tuning. Finally we need the tolerances and required dimensions.

Save Money On Your OEM Washer Nozzle - 76810thra01 - For Your 2018-2024 Honda Odyssey Vehicle When You Shop With Us Online!

Difficult to actually size reamers, I did a lot of reaming to tight tolerances on aircraft parts. Different sizes are easily achieved with one reamer in holes of the same diameter and materials.

Standard reamer sizespdf

Tungsten steel is attributed to hard alloy, but hard alloy is not necessarily tungsten steel, tungsten steel is made of steel process in molten steel.

You can buy a standard tolerance reamer, and carefully lap the OD to make the closer tolerance hole. The better reamers I find are the ones that have un even flute distribution. For accurate holes, I pre bore with a undersize reground end mill or I make a single point cutter that effectively will bore the hole in the correct position. Then ream.

Northern Hydraulics. Hydraulic Cylinders · Hydraulic Valves · High pressure bolting tools · Flange Maintenance Tools · Log Splitters · Hydraulic Hoses · Coolers ...

Get discounts for 30pcs/set 14.4*5.9*2.1cm Diamond Burr Bits, Drill Bit Set For Rotary Tools Metal Woodworking Router Sanding Carving - 1/8" (3mm) Shank ...

The term "flute" was originally applied both to pipe instruments held sideways and pipe instruments held vertically. Thus, the vertically held recorder was also ...

This is why I prefer to bore anything 8mm and over where possible as you have more control over the fit, For example on the crankshaft of an engine just finished I had a press fit for the crank disc, push fit for the flywheel and running fit for the bearings. Had I done it with reamers I would have needed 3 different sizes or tolerances and possibly mucked up parts testing to see how they actually cut.

You don't have to choose between your pet and your wallet when it comes to expensive vet visits. Prepare ahead of time for unexpected vet bills by finding the pawfect pet insurance.

Reamertool

Home › Forums › Beginners questions › Reamer specifications ? This topic has 11 replies, 10 voices, and was last updated 20 January 2020 at 12:13 by JA. Viewing 12 posts - 1 through 12 (of 12 total) Author Posts 19 January 2020 at 19:40 #447637 Former MemberParticipant @formermember19781 [This posting has been removed] Advert 19 January 2020 at 19:40 #10044 Former MemberParticipant @formermember19781 19 January 2020 at 20:08 #447644 EmgeeParticipant @emgee Have a look here for starters **LINK** Emgee 19 January 2020 at 20:09 #447646 old martParticipant @oldmart Difficult to actually size reamers, I did a lot of reaming to tight tolerances on aircraft parts. Different sizes are easily achieved with one reamer in holes of the same diameter and materials. Ream dry, the largest size hole. Wipe the reamer with an oily cloth and remove as much as possible, smaller hole. Oil the hole and reamer well, smaller still. There are other methods I would not want to talk about. 20 January 2020 at 02:04 #447689 Enough!Participant @enough …. but how does that relate to reamer specifications (H7, H8 etc) ? 20 January 2020 at 05:55 #447691 Michael GilliganParticipant @michaelgilligan61133 I suspect that I would struggle to afford any of these : **LINK** http://www.re-al.ch/en/technical-features/standard-tolerances … but it’s an interesting glimpse at ‘how the other half lives’ MichaelG. 20 January 2020 at 06:52 #447692 DiogenesIIParticipant @diogenesii Fwiw, Taylor & Jones have an excellent "All you ever wanted to know about reamers.." pdf; taylorandjones.co.uk/wp-content/uploads/2014/03/31-40_technical_section.pdf link ..apologies for the clumsy link.. but worth looking at.. Edited By DiogenesII on 20/01/2020 06:56:14 Edited By JasonB on 20/01/2020 07:08:42 20 January 2020 at 07:05 #447694 JasonBModerator @jasonb If they are old imperial reamers I doubt yours will have ISO tolerances. Most of my newer ones have it on them. If you look up the tolerence you want on the link posted then you buy a suitably spec'd reamer though as Old mart says the actual hole you will get will vary depending on several factors, I suspect there is some criteria for testing reamers so they can be sold as H7, H8, etc This is why I prefer to bore anything 8mm and over where possible as you have more control over the fit, For example on the crankshaft of an engine just finished I had a press fit for the crank disc, push fit for the flywheel and running fit for the bearings. Had I done it with reamers I would have needed 3 different sizes or tolerances and possibly mucked up parts testing to see how they actually cut. 20 January 2020 at 08:40 #447704 Former MemberParticipant @formermember19781 [This posting has been removed] 20 January 2020 at 09:14 #447714 Neil LickfoldParticipant @neillickfold44316 You can buy a standard tolerance reamer, and carefully lap the OD to make the closer tolerance hole. The better reamers I find are the ones that have un even flute distribution. For accurate holes, I pre bore with a undersize reground end mill or I make a single point cutter that effectively will bore the hole in the correct position. Then ream. For important hole sizing, I make a test hole and measure it. Then if needed, lap the od some more and re test again. I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit. Different cutting fluids etc will vary slightly the result , and so will the cutting allowance etc. Castor oil can make a hole smaller than the reamer, but only by 2 to 4 um. But is not absolute guarantee though. Castor oil will allow oversized parts to assemble that would other wise be a press fit. Down side, castor oil makes an ugly mess over time. Some places that make carbide reamers, will often ask for a size limit or the size you want with the maximum and minimum size. Like a Ø4.494mm reamer with an upper limit of Ø4.496mm , these will cost like 60 to 70 pounds each like the example I gave . 20 January 2020 at 11:19 #447748 HopperParticipant @hopper Posted by Neil Lickfold on 20/01/2020 09:14:27: …I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit. I believe that is so the reamer is within H7 tolerance when new and stays within tolerance for maximum time as it wears. Commercial industrial reamers are designed to last for up to 30,000 holes and stay within tolerance. If they start out at the small end of the scale, they don't last long before being below tolerance due to wear. 20 January 2020 at 12:13 #447757 JAParticipant @ja The coding on the reamer, such as H7, defines the expected tolerance that it would give. While this is of little interest to model engineers it is of great importance in manufacturing where interchangeability is a must. I will give a simple description on how it works. For example, we want a 10,00mm shaft which slides in a bush (a sliding fit is between a push fit and a nice rotating fit). The established standard kindly gives a chart which suggests a hole and shaft tolerance – H7 & g6 (upper case = hole, lower case = shaft). The number gives the machining process that will achieve the required tolerance with ease. It shows that we should be able to achieve the tolerances by grinding, broaching, reaming, boring or tuning. Finally we need the tolerances and required dimensions. The hole requires a tolerance of 0 to +18 μm and the shaft -6 to -17 μm. It follows that the dimensions are 10,000 to 10,018 mm for the hole and 9,983 to 9,994 mm for the shaft. A 10mm reamer marked H7 should give us the correct hole dimension. Fits and limits can get horribly complex and, unless one’s interest was manufacturing engineering, there were usually better things to do. JA Author Posts Viewing 12 posts - 1 through 12 (of 12 total) Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

which suggests a hole and shaft tolerance – H7 & g6 (upper case = hole, lower case = shaft). The number gives the machining process that will achieve the required tolerance with ease.

Nov 11, 2016 — #1 Pull as many as you can with a J-bar. #2 snap the remaining nails off flush with the surface. They are highly tempered and will snap easily, ...

Standard reamer sizesin inches

Depending on the species of the mother plant, burrs can be the size of a pinhead (like beggar’s lice) or substantial enough to deflate a bike tire, like the puncture vine.

I believe that is so the reamer is within H7 tolerance when new and stays within tolerance for maximum time as it wears. Commercial industrial reamers are designed to last for up to 30,000 holes and stay within tolerance. If they start out at the small end of the scale, they don't last long before being below tolerance due to wear.

Burrs are an evolutionary tool developed by plants to move their seeds and promote species continuation. It’s this manner of transportation that makes many burr-producing species invasive. Think of burrs as tiny cactuses; both are considered diaspores due to those painful protrusions. These protrusions act like velcro, allowing them to hitch a ride on passersby.

Some places that make carbide reamers, will often ask for a size limit or the size you want with the maximum and minimum size. Like a Ø4.494mm reamer with an upper limit of Ø4.496mm , these will cost like 60 to 70 pounds each like the example I gave .

Burrs are a pain in the side, not only for pets but also for the people who care for them. Hopefully removing those aggravating buggers will be a little bit easier using this tried-and-tested guide. Want to learn how to rid your dog of other annoying hitchhikers? Check out our guide for removing ticks on dogs.

Planning to head out on an adventure with your pooch? Make sure you’re protected against accidents and illnesses. Secure pet health insurance

Chucking Reamers

Search for: Home › Forums › Beginners questions › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post The Latest INDEX to Model Engineers’ Workshop 1 2 Started by: David Frith in: Model Engineers’ Workshop. 7 27 24 November 2024 at 22:39 David Frith Mach3 problem? Started by: Paul Mills 4 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools 2 4 24 November 2024 at 22:34 Paul Mills 4 Thread pitch of screws used on Stihl equipment Started by: Bill Phinn in: Workshop Tools and Tooling 7 12 24 November 2024 at 22:19 Michael Gilligan EN8M FLAT Started by: Dougie Swan in: Materials 4 6 24 November 2024 at 21:36 Clive Brown 1 Strange drilling situation Started by: gerry madden in: Workshop Techniques 15 17 24 November 2024 at 20:19 Michael Gilligan Creworks Lathes on Amazon UK – some big price drops for Black Friday Week Started by: Lee Cooper in: Manual machine tools 8 12 24 November 2024 at 19:51 Lee Cooper What is (Traditional) Model Engineering? 1 2 Started by: Martin Kyte in: General Questions 23 43 24 November 2024 at 19:40 bernard towers FreeCAD version 1.0 released Started by: Russell Eberhardt in: CAD – Technical drawing & design 9 18 24 November 2024 at 19:21 Andy Stopford modifying Schaublin collets 1 2 Started by: Ken Weeks in: General Questions 14 26 24 November 2024 at 18:10 vic newey A blast from the past Started by: Michael Gilligan in: The Tea Room 13 18 24 November 2024 at 17:43 Nigel Graham 2 What did you do Today 2024 1 2 … 18 19 Started by: JasonB in: The Tea Room 68 475 24 November 2024 at 17:02 Dalboy Traction Engine Identification Help Please…. Started by: Bill Morgan in: Traction engines 8 11 24 November 2024 at 16:07 Dave Halford Subscription via pocketmags Started by: chris hammerton in: Subscription issues and Digital magazines 2 2 24 November 2024 at 15:56 Michael Callaghan Choosing a suitable fine point capacitive phone stylus Started by: Greensands in: The Tea Room 5 6 24 November 2024 at 12:50 Weary Co-ordinate positioning for circle of holes (not all equally spaced) Started by: Zebethyal in: Help and Assistance! (Offered or Wanted) 7 17 24 November 2024 at 12:49 John Haine Bronze Started by: Garry Coles in: Materials 6 6 24 November 2024 at 12:25 Mick Bailey Westbury Cam Turning Jig Started by: Clive Brown 1 in: I/C Engines 5 7 24 November 2024 at 10:56 Graham Meek ML10 questions Started by: 1957jmh in: Beginners questions 15 25 24 November 2024 at 10:34 Howard Lewis chenery 9 cylinder gnome Started by: charlie9cyl in: I/C Engines 7 10 24 November 2024 at 10:02 noel shelley Measurement history Started by: JohnF in: The Tea Room 6 12 24 November 2024 at 09:39 JohnF maid of kent valva gear Started by: wireman in: Introduce Yourself – New members start here! 2 2 23 November 2024 at 22:13 Nigel Graham 2 Colchester/Harrison VS Lathe Started by: Brad White in: Workshop Tools and Tooling 1 1 23 November 2024 at 17:27 Brad White A couple of ‘soon to be available in the UK’ lathes that look interesting 1 2 Started by: Lee Cooper in: Manual machine tools 11 32 23 November 2024 at 16:50 Michael Gilligan Twin mill engine progress Started by: AStroud in: Work In Progress and completed items 3 4 23 November 2024 at 16:19 AStroud BLACKMAIL Started by: Howard Lewis in: The Tea Room 11 18 23 November 2024 at 15:36 Michael Gilligan Viewing 25 topics - 1 through 25 (of 25 total)

If you look up the tolerence you want on the link posted then you buy a suitably spec'd reamer though as Old mart says the actual hole you will get will vary depending on several factors, I suspect there is some criteria for testing reamers so they can be sold as H7, H8, etc

These prickly balls house seeds and allow them to move further than they would on their own, with animals as the transport vessel. Dogs aren’t the only animals affected by burrs. They’ll stick to anything resembling fur, even your favorite cardigan or footwear.

The hole requires a tolerance of 0 to +18 μm and the shaft -6 to -17 μm. It follows that the dimensions are 10,000 to 10,018 mm for the hole and 9,983 to 9,994 mm for the shaft. A 10mm reamer marked H7 should give us the correct hole dimension.

GSP - High Tech Saws, sro, resident in Zborovice, is a traditional cutting tools (slitting saw) producer.

Since burrs stem from plants, technically a commercial weed killer will work, but these aren’t advised for several reasons. First, weed killers are often poisonous to pets, pollinators, and beneficial insects. These chemicals can also make their way into water and food sources, so we don’t recommend using these as the first line of defense.

Threading insert IR vs. EL, or ER vs IL, NR, NL etc. - threading insert nomenclature. 2024-06-30 17:35:15. Wallers Industrial Hardware dispatches same ...

The Toxics Release Inventory (TRI) is a publicly available database containing information on toxic chemical releases and other waste ...

Fits and limits can get horribly complex and, unless one’s interest was manufacturing engineering, there were usually better things to do.

2024924 — SFM stands for surface feet per minute and defines the relative linear velocity between the cutting edge of a tool and the workpiece.

For important hole sizing, I make a test hole and measure it. Then if needed, lap the od some more and re test again. I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit.

Reamers

Hunters often use vegetable oil-based cooking sprays to prevent burrs and make removal easier. Vegetable oil is better than body oils or baby oil since it’s safe for your dog to ingest.

The coding on the reamer, such as H7, defines the expected tolerance that it would give. While this is of little interest to model engineers it is of great importance in manufacturing where interchangeability is a must.

Standard reamer sizesin mm

Different cutting fluids etc will vary slightly the result , and so will the cutting allowance etc. Castor oil can make a hole smaller than the reamer, but only by 2 to 4 um. But is not absolute guarantee though. Castor oil will allow oversized parts to assemble that would other wise be a press fit. Down side, castor oil makes an ugly mess over time.

Reamersize chart PDF

Removing burrs from dog fur isn’t difficult, but it can be time-consuming. Burrs typically attach to long-haired dogs, causing the fur to knot. Untangling the coat is the most challenging part of burr removal, and it will require some cooperation from your dog. Unfortunately, sometimes the tangles are so nasty your only choice is to cut them out.

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

Burrs are a real pain in the fur. Not only are these sticky suckers painful and irritating, but they can cause mats and skin irritation. In this article, we’ll explain what burrs are and how to get them off your fur-baby’s locks.

For example, we want a 10,00mm shaft which slides in a bush (a sliding fit is between a push fit and a nice rotating fit).

…I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit.

0086-813-8127573

0086-813-8127573