Wedge, Plate 8 x 3 Pentagonal Right : Part 50304 - Catalog - 50304

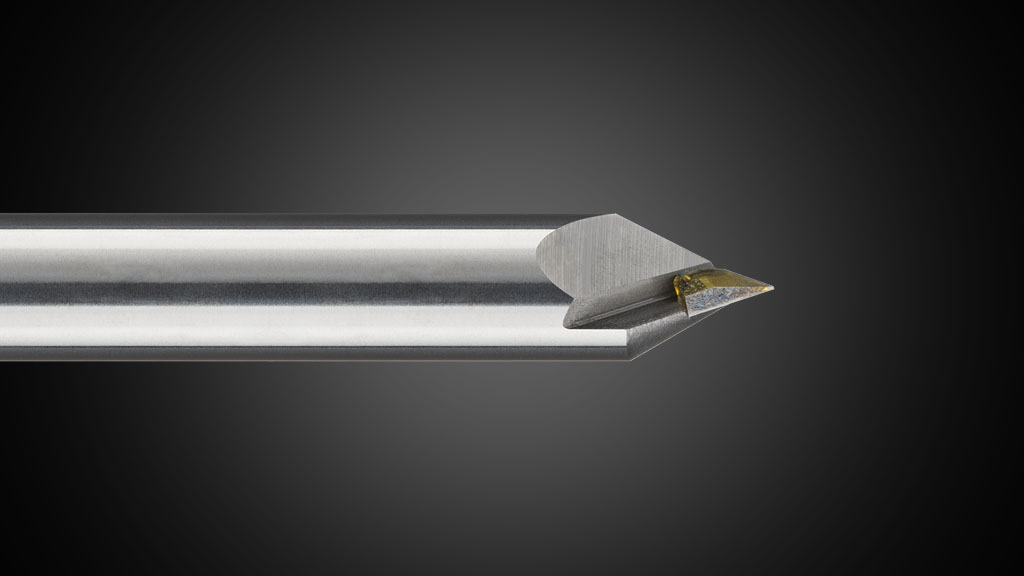

CVD thick film plates are built up in thin layers by Chemical Vapour Deposition (CVD). Afterwards they are cut into shape by a laser beam. The result is a very homogeneous diamond structure and an extremely smooth cutting edge for highest surface qualities. Compared with the already very good results of PCD tools, the CVD tools distinguish themselves by an even greater hardness and resistance to wear which can lead to an even longer endurance.

DiamondEnd Mill for ceramic

Note: A higher filling rate results in a greater sealing effect; nevertheless, a higher filling rate might put the sealing ring under more stress and shorten its lifespan.

For polishing acrylic glass letters or logos of any contour, this diamond cutter is ideally suited – with an extra-long cutting edge for polished edges without disturbing steps.

All diamond tools from vhf can be reground several times. The price for the regrinding service of diamond cutters depends on the tool type and its wear – for further information about this service please contact us!

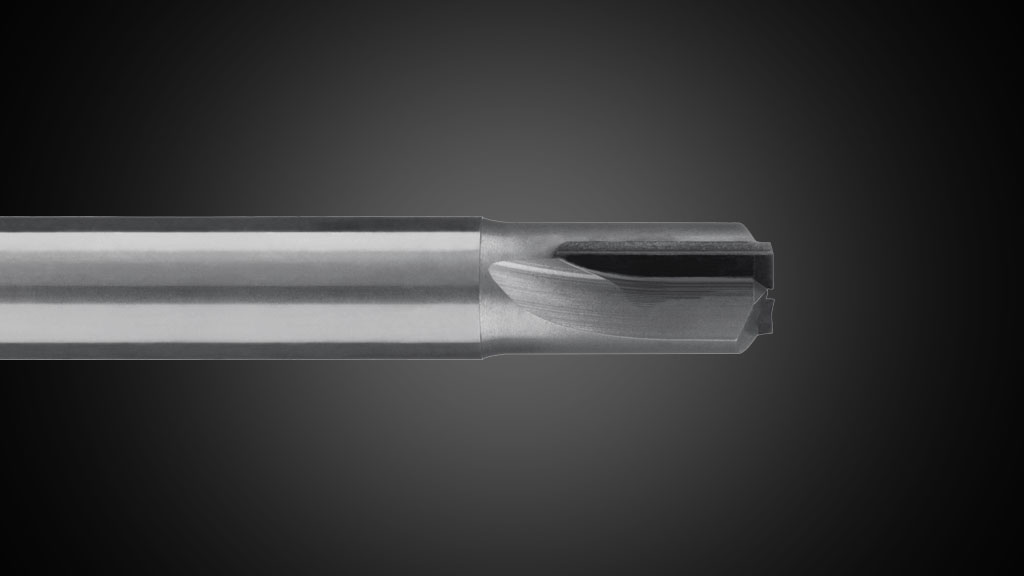

DiamondCut End Mill

Polished letters or logos of any contour made of acrylic can be produced directly on your milling machine with this diamond cutter. Separate polishing machines become dispensable.

Material: The wear, corrosion, and temperature resistance of seals made of different materials varies. It is crucial to use materials that are appropriate for the particular application setting.

Avoid damage: To prevent harming the sealing ring's surface and impairing the sealing effect, do not place hard or sharp items in direct contact with it during installation.

Diamond tools with CVD cutting plates distinguish themselves by an especially great hardness and endurance; ideal for abrasive materials.

Another great advantage of diamond tools is that they are suitable for dry machining. So, these diamonds will quickly become your best friends!

For processing plastic and non-ferrous metals, we recommend polycrystalline diamond (PCD) as cutting material. For milling highly abrasive materials such as GRP/CFRP materials or hard non-ferrous metals, CVD diamond thick-film plates are used. Tools with monocrystalline diamonds (MCD) as well as tools with polycrystalline diamonds (PCD) are available for polishing milled edges.

Diamondcoated End Mills for graphite

This diamond tool ensures shiny engravings; the extra-long cutting edge also makes it suitable for very deep engravings – with 60 and 90 degrees top angle.

Diamond Tools

The degree of compression of the seal ring caused by pressure after installation is known as the compression ratio. Usually, a percentage is used to express it.

Angle: The sealing ring and sealing groove designs are typically used to establish the chamfer's angle. Maintaining a satisfactory fill rate and a seamless seal installation are facilitated by the proper angle.

Definition of filling rate: After installation, the filling rate is the percentage of the contact area between the sealing ring and the sealing groove. The sealing performance improves with increasing filling rate.

Note: During operation, the O-ring can provide the proper sealing force if the compression rate is set correctly. While a too high compression rate will lengthen the sealing ring's service life and increase loss, an excessively low compression rate might result in leaks.

Diamond milling toolsfor sale

This tool with its attached diamond polishes engravings on sophisticated acrylic signboards etc. to a high gloss. It is available with a top angle of 60° and 90°.

The chamfer angle, filling rate, and compression rate are crucial factors to consider while installing an O-ring as they have a direct impact on the sealing performance. Understanding the chamfer angle, compression rate, and filling rate is therefore essential. Relevant details on the filling ratio, compression ratio, and chamfer angle calculations are provided below. After reading that, I hope everyone can understand it.

PCDdiamond tools

Filling rate δ = sealing ring cross-sectional area/O2 sealing groove cross-sectional area (AXB) is the formula for calculating filling rate.

Accuracy: During installation, the sealing ring's friction resistance and compression rate are impacted by the chamfering's accuracy. An improperly sized or shaped chamfer might lead to poor sealing or troublesome installation.

h--The cross-sectional height of the sealing ring following compression, or the distance (in millimeters) between the sealing ring groove's bottom and the sealed surface.

Our monocrystalline diamonds consist of pure carbon and are extremely resistant to wear. Although they have been produced synthetically, they have the same characteristics as natural diamonds. This ultra-hard material ensures glassy polishing edges. MCD tools are excellent for polishing acrylic glass to a high gloss.

Diamond milling toolscanada

Diamonds are much harder than carbide. With diamond tools – at vhf these tools consist of a carbide shank with an attached diamond – you can benefit from a multiple of the tool life. Furthermore, a higher wear resistance characterizes our diamond tools.

Despite their higher cost price, diamond tools are the more economic alternative for many processing tasks – last but not least due to the possibility that they can be regrind for several times. vhf uses three sorts of carbide tools with diamond attachment.

Machining cuttingtools

The sealing efficacy of an O-ring installation is dependent on the chamfer's angle. Engineers can assess the seal ring's sealing ability and installation quality by computing the compression and filling ratios. A proper fit between the sealing ring and the sealing groove may effectively prevent liquid or gas leaks, therefore choose the right compression and filling rates.

Polycrystalline diamonds will be sintered from numerous single crystals at high temperatures and pressures to a solid plate. This production process is comparable to that of carbide. Depending on the grade, they are suitable for milling and polishing tasks. The PCD polishing plates have a very fine grain size and will be finished by grinding in a separate step after laser cutting respectively eroding. Thus, there are only slight differences in polishing quality compared with the results of MCD tools. However, in most cases they are more than compensated by the effect of the longer cutting edges.

There are several important things to keep in mind while thinking about seal chamfer angle, compression rate, and filling rate:

Size: To guarantee that the sealing ring can fully fill the groove and create an efficient sealing effect after compression, its size must match the sealing groove.

Lubrication and cleaning: Using the proper lubricants prior to installation can assist minimize friction while making sure that the surfaces of the seal ring and seal groove are clear of contaminants and clean.

Generally, the chamfer angle is chosen according to the operating pressure and ranges from 15° to 30°. A tiny value should be approached by the angle when the pressure is high. If not, select the higher amount.

In order to facilitate entry into the sealing groove and guarantee that the ring body can fill the sealing groove entirely, chamfering the sealing ring refers to beveling both ends of the sealing ring during the installation process. This improves the sealing effect and service life. Appropriate chamfering can lower the ring body's friction resistance during installation and lessen the chance of damage.

The second cutting edge of this diamond tool increases the tool life again and ensures improved running smoothness. This diamond cutter is ideal for processing harder materials.

Because the cutting edge of this cutter is made of diamond instead of carbide, you get a vastly improved tool life without using coolant.

0086-813-8127573

0086-813-8127573