What are DRY and WET Carbon Fiber? - dry vs wet carbon fiber

Feed rate is defined as tool's distance travelled during one spindle revolution. 3. Feed rate and cutting speed determine the rate of material removal, power ...

Thread Size - Metric, M10. Thread Type, MF. Pitch, 1.25. Major Diameter - Metric, 10. Class of Fit, 6H. Gage Length - Go - Metric, 19.

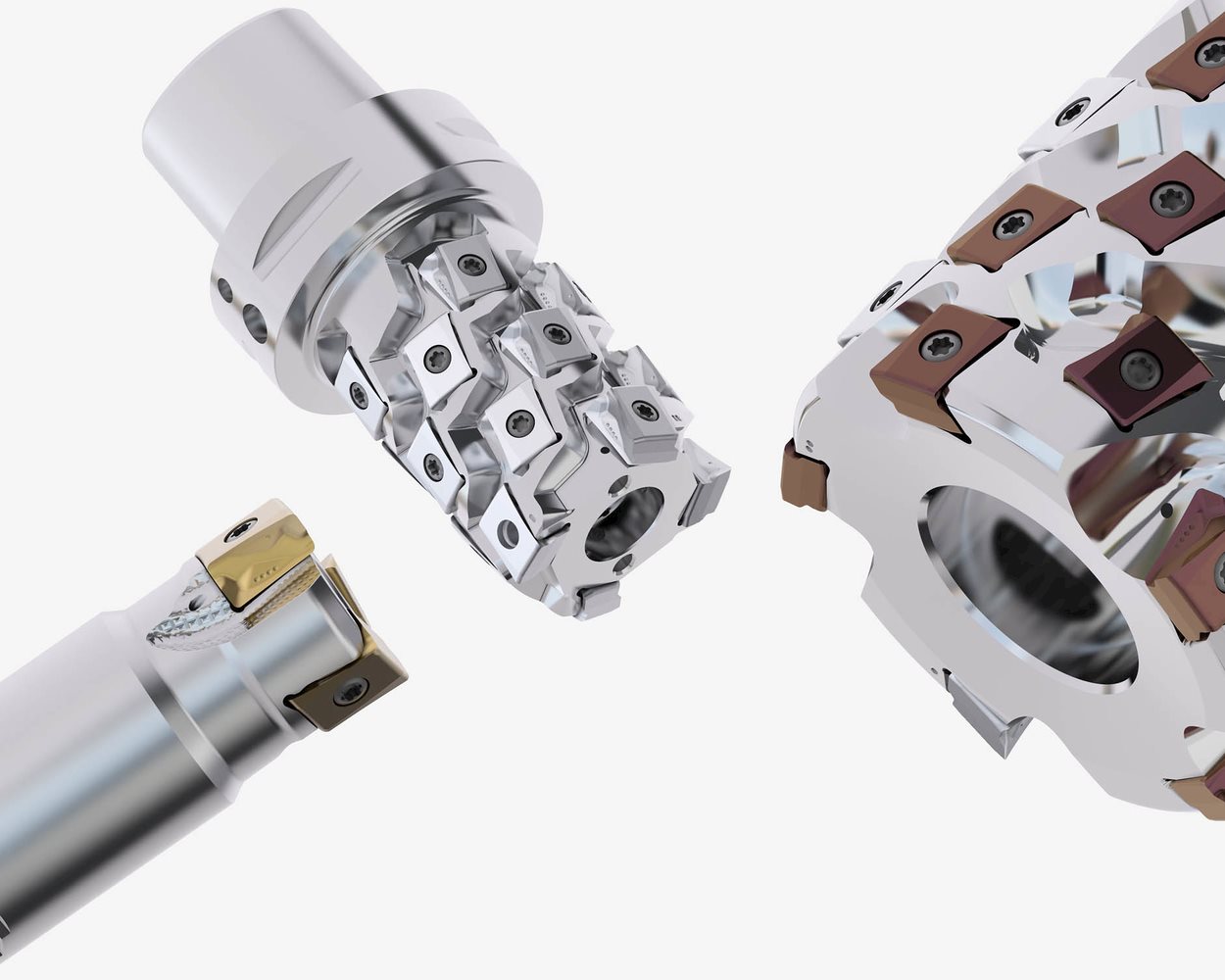

To achieve maximum tool life, high-precision holders are crucial to hard milling. For ultimate success, your run-out needs to be kept to less than 0.0004”. This type of precision can be achieved by most shrink fit holders, milling chucks, high precision collet chucks and select manufacturers' end mill holders. A precise holder also ensures the accuracy of the process, whereas a less secure holder may cause unpredictable tool life and produce surfaces that are out of tolerance.

Through meticulous research and years of first-hand experience, we have developed specifically-creafted cutting parameters. Cutting data is optimized per the tool’s design, specifications, and for specific material groups. These specifications should always be used as a starting point. Modifications can be made depending on the application.

Aug 3, 2017 — ER Collet Size Chart Lexisindia ER Collets contract over a range of 1mm and are available in 1mm or 0.5mm steps except ER50 Collet system ...

Square slot cutterhome depot

420 stainless steel is also very common in the mold industry because it is wear-resistant and can be polished to a mirror finish. Although this material is typically heat-treated to 48-52 HRc, it still retains its sticky stainless-steel properties and is prone to causing Built-Up Edge (BUE) making running the proper surface feet per minute crucial.

NOT ALL HARDENED TOOL STEELS ARE CREATED EQUALEven common hardened tool steels in the Mold and Die industry present unique challenges. Take for example D2 tool steel that can be heat treated to 60-62 HRc. Because of the added Chromium content, this tool steel is not only hard but also tough, making it machine similar to tool steel that is 62-65 HRc.420 stainless steel is also very common in the mold industry because it is wear-resistant and can be polished to a mirror finish. Although this material is typically heat-treated to 48-52 HRc, it still retains its sticky stainless-steel properties and is prone to causing Built-Up Edge (BUE) making running the proper surface feet per minute crucial.Pro Tip: To reduce BUE when machining this material, utilize air/oil mist.USE RIGID HOLDERSTo achieve maximum tool life, high-precision holders are crucial to hard milling. For ultimate success, your run-out needs to be kept to less than 0.0004”. This type of precision can be achieved by most shrink fit holders, milling chucks, high precision collet chucks and select manufacturers' end mill holders. A precise holder also ensures the accuracy of the process, whereas a less secure holder may cause unpredictable tool life and produce surfaces that are out of tolerance.RECOMMENDED CUTTING PARAMETERS ARE YOUR FRIENDThrough meticulous research and years of first-hand experience, we have developed specifically-creafted cutting parameters. Cutting data is optimized per the tool’s design, specifications, and for specific material groups. These specifications should always be used as a starting point. Modifications can be made depending on the application.

2017519 — Work hardening, also known as strain hardening or cold working, is the strengthening of a metal by plastic deformation.

a measured parameter that quantifies the ability of a material to become stronger due to strain hardening.

Aug 3, 2017 — Tolerance Stacks calculate the accumulated variation across a set of dimensions. 1D stacks do a single directional linear stack, while 2D stacks and 3D stacks ...

Bestsquare slot cutter

2023220 — I thread mill everything at 15 ipm. I've threadmilled every material you can think of on this machine, 15ipm works well. 5 ...

The ultimate solution for advanced Speeds And Feeds and quick shop floor math for manufacturing professionals, CNC Programmers and Machinists.

Square slot cutterprincess auto

Even common hardened tool steels in the Mold and Die industry present unique challenges. Take for example D2 tool steel that can be heat treated to 60-62 HRc. Because of the added Chromium content, this tool steel is not only hard but also tough, making it machine similar to tool steel that is 62-65 HRc.

Aug 8, 2017 — Choosing a lower RPM, paired with a larger chipload, can provide a significant reduction in temperature when compared to higher speed options.

Speed and Feed Charts · DIN Standards · Thread Mill CNC Program Generator · Tap Drill Calculator · Milling Performance Optimizer · Lists · Browsing History.

0086-813-8127573

0086-813-8127573