What Is a Machinist? - what a machinist does

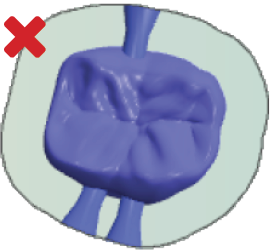

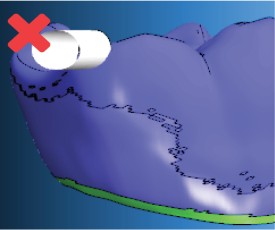

If you place bars on only one side, vibration during machining may occur. This can lead to the blank or tool getting damaged.

For milling titanium on a S1 or S2 year of manufacture < 2016 with a wet grinding module, a flow sensor needs to be retrofitted. Contact customer service for this. After installing the flow sensor, you need to unlock your abutment holder as extra equipment. The unlock code is sent to you together with the abutment holder.

The maximum values for tool service life that you can actually achieve with your tools depend on many factors, such as the quality of the tools, the quality of the blanks, machine maintenance and cleaning, etc. Therefore, the maximum service life that DentalCNC specifies on delivery are standard values that must be adjusted until they correspond to the maximum values you can achieve.

We highly recommend the use of original vhf tools for optimal results and a high service life of your machine and its components.

The tool life depends on the bending strength of the processed material. Different bending strengths result in different tool life.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Hours ... South Texas Milling Inc is a reputable company based in Inez, TX that specializes in providing milling services to clients in the South Texas region.

12410-G2 Concave tip for Invar system (TBs having 0.5" diameter ball only) BXT Series extension bars (be sure to match BXT bar to your TB, some TBs do not fit some BXTs) TBA Series (be sure to match TBA adapters to your TB, some TBs do not work with some TBAs)

The inserts have an external thread that resembles a coarse wood screw thread and an inside thread that resembles a fine machine screw thread. You can ...

Roll taps produce stronger and cleaner threads than cutting taps as the lack of swarf means that the tap cannot break as a result of the flutes clogging.

Aug 5, 2011 — be interpreted as inches per minute by the machine tool? In ... minute, such that the equation is: F(code) = 1(minute) / (time = 3D ...

Shop the Niroc Carbide Blade Straightening Hammer at Maritime Knife Supply. This hammer is perfect for blacksmiths, tool makers, and more.

If there isn't enough space between bars, the air nozzle of the spindle may not be able to blow off machining debris as required, which can damage the tool.

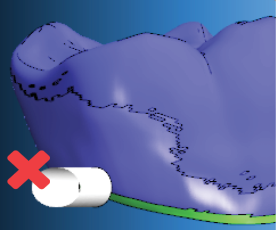

The bar in the figure below is positioned too low. Only a part of the bar is positioned on the object. Additionally, the bar is positioned on the prepline.

18 Followers, 2 Following, 31 Posts - Diamond Harvey (@diamondharvey2017) on Instagram: ""

The table shows all indications that can be machined from titanium on vhf machines and the most suitable machines for these indications.

Drilling Speed and Feed Calculator · Cutting feed (IPR) · Spindle speed (RPM) · Feed rate (IPM) ...

... insert grade for parting and grooving here. Overview. GC1225. First-choice grade GC1225 ... grooving, now includes inserts and tools down to widths of 1 mm.

You should at least set 3 bars for each object. Multi-unit-objects generally require 2 bars per unit. Otherwise, vibrations may occur during machining, which can lead to the blank or tool getting damaged.

Brunson Instrument Company has been producing measurement solutions since 1927. Learn more about our history, who we are, and get to know more about metrology.

Home > SURPLUS TOOLING > 1/2" DIA., 90 DEGREE MULTI FLUTE, CARBIDE BACK CHAMFER TOOL. 1/2" DIA., 90 DEGREE MULTI FLUTE, CARBIDE BACK CHAMFER TOOL.

Tooling Solutions is a distributor of High Performance Metal Cutting Tools including Carbide Inserts, Drills, Taps, Reamers, Endmills, and more!

0086-813-8127573

0086-813-8127573