What is Depth of Cut in Machining? Its Unit, Value, Effects ... - depth of cut

It’s among the more popular aluminum alloys in its series, including alloy 6005, 6061, and 6063. Alu6082 is formed by extrusion and rolling.

Working with aluminum in a CNC machine can present some challenges that are unique to this material. Here are 10 tips from the experts at WorthyHardware on how to overcome these challenges and get the best results from your aluminum machining projects:

It would appear, then, that all you need to do is optimize the cutting tool impact timing and all will be well any time you use that particular cutting tool. However, the impact frequency involves more than just the cutting tool itself. No matter how rigid a machine tool may be, there are a number of parts involved in the cutting process that impact the accuracy of a cut: The cutting tool, the tool holder, the collet, the spindle, spindle bearings and the motion of the headstock. All of these have some degree of play that results in deflection of the cutting tool as it impacts the workpiece.

Aluminum has been and is still an excellent option for CNC machining and milling and it’s readily available in machine shops. Unlike other materials, aluminum is known to be a soft and pliable metal.

With these tips in mind, you will be able to work more effectively with aluminum in a CNC mill and achieve the best results for your projects.

Tool are one of the most successful progressive rock bands of the past twenty years. ... over a 15-year timespan, and nothing since 2006. Nevertheless, ...

For this reason, it has many advantages that give it excellent machinability. Here are why you should choose aluminum for all your CNC machining and milling purposes.

Blue chip machiningprocess

Unlike any other most popular aluminum alloy, 6082 cannot be hardened, but it is heat treatable and therefore produces tempers with high strength but lower ductility.

This Internet-based “stability improvement technology” uses a special hammer equipped with a transducer to tap the tool and holder assembly mounted in the machine tool. The hammer device records the frequency response for the unique tool, holder, spindle and machine combination. This data is encrypted and sent through the Internet for analysis. The result is posted to a dashboard that the machine operators can view on their computer screens, and which graphically presents the precise stable speeds, feed rates, width and depth of cut for optimum operation.

Moreover, due to its low friction coefficient and high corrosion resistance, brass is used for applications in engineering, plumbing, steam work, and musical instruments.

The significant mechanical properties of this brand include poor formability and weldability, fine machining, and average corrosion resistance.

Blue chip machiningcost

As you shall see in this article, aluminum is readily available and in different grades. However, desktop CNC mills can still use a variety of other materials.

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English fiber) is a composite material made of a polymer matrix ...

Aluminum material is highly resistant to low temperatures. Steel, which is used in place of aluminum, is quite fragile, especially if working at low temperatures.

In addition, it has excellent corrosion resistance, good formability and weldability, acceptable machinability, and good resistance to wear.

During CNC machining, the alloy machines are well but not as nicely as 6061 and not as bad as 5052. So the end product of 7075 is likely to be a little more like a smooth but dull grey.

ATA Tools Inc. is a leading manufacturer of tungsten carbide burs and fiberglass routers (FGRs) based in Cuyahoga Falls, Ohio.

Different grades of aluminum produce different results in the machine. Therefore, it is vital to know the grade you are working with and how it works.

Al5052 has excellent natural corrosion resistance. Your tools should be very sharp with excellent lubrication for better results with this brand.

Moreover, the brand offers an excellent combination of thermal and mechanical properties, which are ideal for the process. Moreover, like other aluminum alloys, it is heat treatable.

The 6061 is a high-strength alloy preferred for other reasons, such as being easy to mill. It is readily weldable, has excellent corrosion resistance, is easily anodized, and has excellent durability.

CNC is responsible for completing previously tedious tasks for assembling complex parts, including cutting, grinding, forming, and boring, all under computer instructions and prompts.

Among all metals that are used in the process, copper has the highest electric conductivity. For this reason, it is best used in electrical applications.

The brand is one of the most popular aluminum alloys. Its only shortcoming is that it has a little corrosion resistance.

Aluminum can, however, be replaced by other metals that work relatively the same or slightly different. These metals include steel and stainless steel, titanium, brass, and copper.

Aluminum is 100% recyclable, unlike steel and other materials. Moreover, the aluminum chips retain all the original properties during the recycling process.

Moreover, the parts can be plated into various colors of choice. The most preferred and most used colors are black, blue, and green.

CNC machining aluminum produces a lot of waste that is lost in the process. It is therefore advisable to use a metal that will be recyclable.

While many companies’ best-preferred mode is CNC machining aluminum, the metal has limitations that make some companies opt for other materials.

Aluminum is one of the most preferred materials for many CNC aluminum milling projects. Its preference is due to its physical properties, ability to resist corrosion, durability, and cost.

Weldon is a Christian English baby boy name. Its meaning is "Spring, Stream". Weldon name origin is English. , Baby names meaning in Urdu, Hindi.

Copper cannot produce any CNC machined part alone, but its alloys are made to replicate popular aluminum grades' machinability and other abilities.

Blue ChipTool

Feb 10, 2022 — The screw itself would have been a square thread. Acme threads were introduced in 1894, and replaced square threads in most applications.

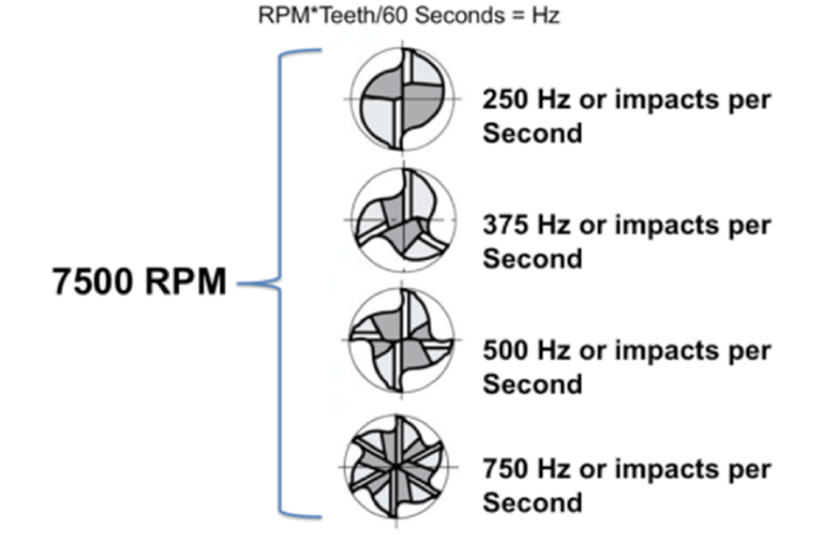

Another factor that impacts frequencies is the number of cutting tool teeth. As the chart below illustrates, the number of impacts per second increases with the number of teeth. At 7500 RPM spindle speed, these vary from 250 Hz to 750 Hz per second.

Since over 200 years ago, milling has transitioned to a more computerized control: the CNC milling process. Have you ever wondered how a CNC mill works and the materials used?

Another reason that makes steel and stainless steel preferred is their ability to resist very high temperatures. In addition, stainless steel can become corrosion-resistant as it is heat treatable

Anodization is the process of using a surface finishing procedure to thicken the protective already oxidized outer layer of metal parts.

For effective CNC machining and milling, the choice of the milling material dictates the final results. The market provides different materials, including aluminum, stainless steel, brass, titanium, copper, and other metal brands.

Cobalt End Mills ... Sale! ... Sale! ... Sale! ... Sale! From $ 7.08 $ 9.00. Tialn Coated M42- ...

The Alu2024 has a high strength to weight ratio and it’s machinable. However, this brand is known to chip at the end of heavy cuts with the tool breaks out.

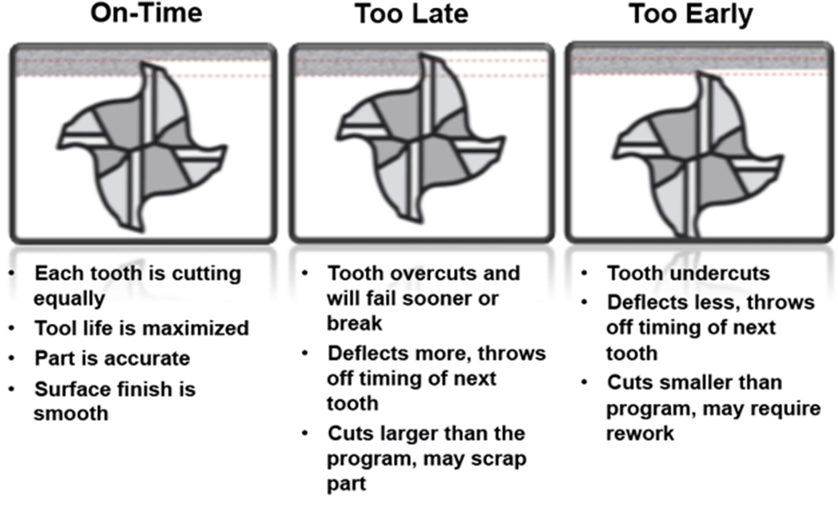

If these frequencies are compatible, each tooth impacts the workpiece at the same time, achieving uniform chip thickness. The cut is quiet, surface finish is smooth, the part is accurate and tool life is maximized.

When we machine metal of any kind, the chips – or swarf – give us clues about the efficiency of our cutting process. For example, early machinists noted that blue chips indicate heat is being properly dissipated, so the cut was going well. Blue swarf, therefore, were considered “perfect” chips.

However, Alu6082 is not used in casting due to its tensile strength. The brand can also be forged and clad, but that is not common practice with this alloy. Like most aluminum brands it has a high strength to weight ratio.

If you require service any time, day or night, just one call to 866.385.2798 gets you a fast, reliable response from Gosiger service.

Although aluminum falls behind in terms of these mechanical properties, steel is hard metal compared to metal aluminum but less machinable.

Aluminum alloy has a thermal conductivity of 121-151/W· (m·k). The competitor metal, stainless steel, has a thermal conductivity of 58.6-41.9/W· (m·k).

A CNC router for milling is available all over the internet. Like any other digital invention, Computer Numerical Control (CNC) machining has come as a relief in the machining industry.

The tool's travel distance during a single spindle revolution is referred to as the feed rate. It is referred to as the cutter feeding speed.

In addition, titanium is unique in its high-temperature melting point. The molten material is ideal for many industries and applications.

Due to its light in weight nature and short processing time, aluminum has a low cost in comparison to others. It is, therefore, a preference for low profile and high profile companies.

However, if you are not careful with exiting the material on very heavy cuts, it presents a high risk of chipping due to its tensile strength.

Processes such as cutting, grinding, forming, and boring require easy work with the material. However, unlike others, aluminum can be turned easily because of its thickness and strength-to-weight ratio.

Blue chip machiningmachine

Cutting aluminum is easier than cutting any other metal. Moreover, you can have various aluminum shapes through stamping and processing in the CNC mill.

If the timing is off and the next tooth arrives too late, it creates a larger than programmed chip load, causing the tool to deflect more and thus throwing off the timing of the next tooth. As a result, the tool will fail sooner and possibly scrape the part. Conversely, if the tooth arrives too early, it undercuts the programmed dimension and throws off the timing.

Aluminum is known to have tight tolerances (approx ±0.025 mm). For this reason, it can be turned into different chips and shapes with ease.

Additionally, others may prefer a less expensive alternative or one with lower energy costs of production compared to aluminum.

10pcs Threading Insert trapezoidal Lathe Thread Tool Blade Carbide Thread Insert 16ER/IR 22ER/IR 1.5TR 2TR 2.5TR 3TR 4TR 5TR 6TR

Today there are more precise ways to optimize machine tool performance. One such method is the technology of Machining Dynamics that focuses on tool point or cutting tool behavior during the machining process. This technology is the basis for a system pioneered by a company called Blue Swarf. This method enables machinists to compensate for the inherent vibration and frequencies created during the machining process.

Cobalt & HSS Drills Speeds & Feeds. Material. Grades. SFM. Tool Diameter (IPR) ... These tools can be found on pages 293-317. High Speed Steel Drills Feed Rate.

Amongst all the aluminum brands, this is the softest brand. Its strength to weight ratio is a bit low. It is mainly used to form applications and marine applications.

Aluminum can generate a protective coating naturally. The coating is formed when the metal comes into contact with an oxidizing environment.

Titanium is, however, impervious to ductile, salt, and water. Titanium is used in aerospace for aircraft components and healthcare industries for medical devices.

However, it is more expensive to work with compared to aluminum. The titanium also carries double the strength for a similar weight.

For the best choice of material in CNN milling, feel free to contact Worthy hardware for professional advice and guidance.

Deskar Tungsten carbide Turning insert for Stainless Steel Indexable Lathe Groove Inserts CNC cutting tools for metal

Visit the Blue Swarf Website to learn more about this unique technology and watch a video presentation on the subject. Or contact the applications experts at Gosiger for this and other ways to maximize your machine tool performance.

Depending on the alloy of the steel, its best applications include commercial products, parts that require strong welds, gears, shafts, and other high-stress applications.

Aluminum materials have great electrical conductivity compared to other commonly used materials and alloys. For this reason, aluminum CNC machined aluminum parts are ideal for electrical uses.

Aluminum CNC milling is a process of using aluminum for manufacturing a product. The process involves using computerized controls and a CNC router to operate and manipulate machine tools using aluminum to cut and shape stock material.

Although the material is unstable and lacks strength, it is still an alternative in the absence of aluminum. As a result, brass is commonly used in making medical equipment, consumer goods, electrical hardware, and contacts.

Worthy Hardware is a CNC manufacturing and sheet metal fabrication company,including CNC machining services,CNC milling services, CNC turning services, laser cutting services and stamping services.Call us +86-76989919645 or email us [email protected] for more discounts for your projects.

According to Blue Swarf’s founders, Machine Dynamics focuses on milling because it involves a number of cutting teeth entering and exiting a workpiece throughout machining. These motions can create chatter that reduces cutting accuracy. In other operations, such as turning, drilling and boring, the cutting tool is in continuous contact with the workpiece, thereby lessening the impact.

There are actually two frequencies created during the milling process. Tooth Impact Frequency occurs when a cutting tool impacts the workpiece, and is determined by the number of teeth on the tool and the spindle speed. Tool Point Frequency involves the flexibility of the tool point, the number of times per second a tooth comes in contact with the workpiece, and the cutting forces applied by the tool for a specific depth and width of cut.

Because there are so many variables that contribute to chatter, there is no easy way to make the necessary adjustments to minimize chatter. Through trial and error you can attempt to improve the situation by adjusting spindle speeds and trying various cutting tools and tool holder combinations, but the time investment is enormous and, odds are, you’ll never achieve the ideal result.

Among other types of aluminum, alu6061 is the total staple for machining. It is an enjoyable metal to cut. Alu6061 is readily available in any machine shop.

Generally, the machinability of aluminum makes work easy and shortens the working duration, making complex aluminum parts more affordable.

Moreover, as these combinations of components change, for example when you take a cutting tool from one machine to another, the frequencies also change because the other components will not be the same. Blue Swarf research indicates that there are over 4.8 quadrillion (4,800,000,000,000,000) possible combinations of machines, tools, tool holders and materials, each of which have their own frequencies.

0086-813-8127573

0086-813-8127573