What is mil thickness? - mill to inch

Titan USA earned its stellar reputation by providing machinists like yourself with premium quality, American-made cutting tools. When you're in need of everything from end mills and drills to taps and reamers, Trust in Titan USA to deliver the best quality tooling at incredible value.

Add products to your Titancuttingtools.com shopping cart and then submit the cart to a participating distributor to place your order

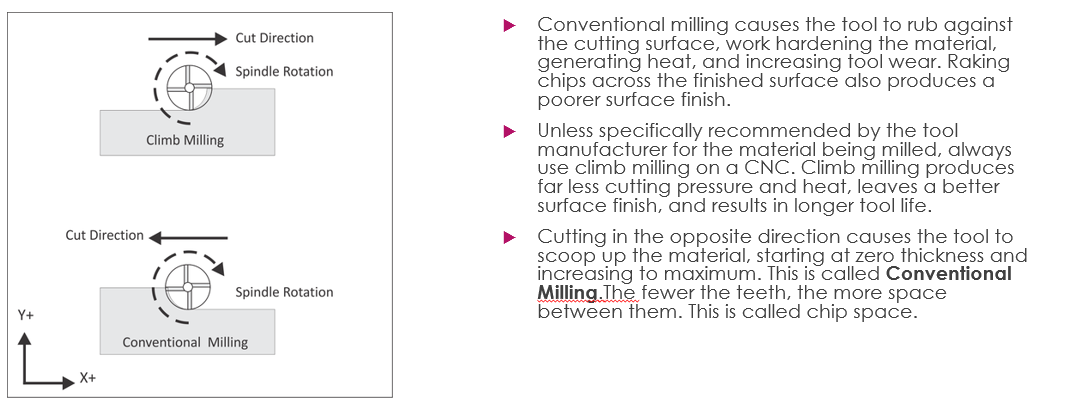

Cutting in the opposite direction causes the tool to scoop up the material, starting at zero thickness and increasing to maximum. This is called Conventional Milling. The fewer the teeth, the more space between them. This is called chip space.

Check real-time stock of all Titan USA products, and find a suitable substitute on the off chance your item is backordered.

Our comprehensive assortment of quality tooling designed for machining aluminum, a staple in today's machine shops, includes both 2 Flute and 3 Flute End Mill options.

Titan USA earned its stellar reputation by providing machinists like yourself with premium quality, American-made cutting tools. When you're in need of everything from end mills and drills to taps and reamers, Trust in Titan USA to deliver the best quality tooling at incredible value.

Check real-time stock of all Titan USA products, and find a suitable substitute on the off chance your item is backordered.

Add products to your Titancuttingtools.com shopping cart and then submit the cart to a participating distributor to place your order

Optimized for deeper drilling applications, featuring black oxide surface finish for increased wear resistance and improved chip flow.

Straight flute reamers engineered for through and blind hole applications, stocked in hundreds of sizes ranging from .0400" to .5020".

Straight flute reamers engineered for through and blind hole applications, stocked in hundreds of sizes ranging from .0400" to .5020".

Milling tools can advance through the material so that the cutting flutes engage the material at maximum thickness and then decreases to zero. This is called Climb Milling.

Optimized for deeper drilling applications, featuring black oxide surface finish for increased wear resistance and improved chip flow.

Our comprehensive assortment of quality tooling designed for machining aluminum, a staple in today's machine shops, includes both 2 Flute and 3 Flute End Mill options.

0086-813-8127573

0086-813-8127573