What is Rockwell Hardness? - hardness of steel

{"Length of Cut - Metric (Lc)":["18","24","30","37.5"],"Number of Flutes":"3","Overall Length - Metric (L)":["100"],"Shank Diameter - Metric (d)":["12","16","20","25"],"Neck Diameter - Metric (d1)":["11","14.4","18","23"],"Cutting Diameter Tolerance - Metric":"+0 / -0.020","Product Overview":"16mm to 25mm, Corner Radius/Square, DLC Coating, Metric Sizes","Neck Length - Metric (L1)":["55"],"Diameter - Metric (D)":["12","16","20","25"],"Helix Angle - Degree":"30","Feature 1":"High Rigidity","Benefit 2":"Excellent chip evacuation","Benefit 3":"Excellent Welding Resistance and Lubricity","Benefit 4":"Exceptional Performance in Aluminum Alloy","Full Description":"High Speed Carbide End Mills for Aluminum Alloy","Short Description":"High Speed Carbide End Mills for Aluminum Alloy","Web Literature 4":"800388CA","Brand":"EXOCARB","Feature 2":"Optimal Flute Shape","List Name":"AERO-ETS","Benefit 1":"Applicable for High Power Equipment","Web Literature 1":"8002024CA-EM,78|8002024CA-EMT,42","Substrate":"Carbide","Cutting Type":"Center Cutting","Shank Tolerance":"h6","Surface Treatment":"DLC","Feature 3":"DLC Coating","View Speed and Feed Page":"Here","View Catalog Page":"Here","Units":"Metric","Aluminum : 6061; 7075":"N; Best","Aluminum : Casting":"N; Best","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Type (feature)":"Reduced Neck","End Cut Type":["Square End","Corner Radius"],"Cutting Direction":"RH","Length of Cut - Specification":"STUB","Helix Direction":"RH","Feature 4":"Sharp Cutting Edge","Corner Radius - Metric (R)":["1","1.6","3","4","5"],"Diameter-Sizes":"12mm - 25mm","Flute-Sizes":"-","Neck-Sizes":"55mm","Taper-Sizes":"-","Overall-Sizes":"100mm","Shank-Sizes":"12mm - 25mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/End_Mills_-_End_Mill_-_List_2973_-_EXOCARB_AERO-DLC_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/DLC-CR-ETL_-_002","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/DLC_with_Haimer_Holder_-_007","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/DLC_-_Machine_-_008","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/DLC_-_Background_Image","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/DLC_-_Part_-_005","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/DLC_-_Part_-_002","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202973/DLC_-_Part_-_001"],"Friendly Name":"2973"}

Tappingholesize

High quality Tungsten Tipped Carbide Insert Parting Tool for CNC Grooving TDJ2 from China, China's leading Carbide Insert Parting Tool product market, ...

Both tapping and drilling require a specific tap or drill bit to be used in order to avoid damage to your material. There are many ways to cut internal holes in a material. However, tapping and drilling are two of the most common – especially for smaller-sized holes.

Both drilling and tapping are common ways to cut internal holes in metal, plastics, wood, or other materials. The main difference lies in how you measure a hole before cutting it into your material.

{"Overall Length - Inch (L)":["4.724409"],"Number of Flutes":["8","6"],"Shank Diameter - Inch (d)":["1","0.625","0.75"],"Neck Diameter - Inch (d1)":["0.960629","0.585826","0.710629"],"Effective Diameter - Inch (DCF)":["0.486","0.304","0.365"],"Cutting Diameter Tolerance - Inch":"+0 / -0.002","Helix Angle - Degree":"0","Diameter - Fractional Size (D)":["1","5/8","3/4"],"Neck Length - Inch (L1)":["2.76"],"Diameter - Inch (D)":["1","0.625","0.75"],"Length of Cut - Inch (Lc)":"0.197","Brand":"EXOCARB","List Name":"AERO HFC-TI","Web Literature 1":"8002024CA-EM,243|8002024CA-EMT,119","Surface Treatment":"BRIGHT","Substrate":"Carbide","Units":"Inch","Web Literature 4":"800388CA","Cutting Type":"Center Cutting","Shank Tolerance":"h6","Type (feature)":"High Feed","End Cut Type":"High Feed Radius","Full Description":"High Feed Radius End Mill for Titanium Alloy","Short Description":"High Feed Radius End Mill for Titanium Alloy","View Catalog Page":"Here","View Speed and Feed Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Helix Direction":"RH","Titanium : 6AL4V (30HRC)":"S; Best","Diameter-Sizes":"5/8\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"2.76\"","Taper-Sizes":"-","Overall-Sizes":"4.724409\"","Shank-Sizes":"0.625\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202080/End_Mills_-_End_Mill_-_EXOCARB_AERO_HFC-Ti_-_List_2080_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202080/OSG_-_Website_-_Product_Overview_-_HFC-Ti_-_3","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202080/OSG_-_Website_-_Product_Overview_-_HFC-Ti_-_2","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202080/End_Mills_-_End_Mill_-_EXOCARB_AERO_HFC-Ti_-_List_2080_-_Extra"],"Friendly Name":"2080"}

They are often used in combination with each other when working with metals. For example, if you want to create a screw hole which extends deeper than 1 thread then you will use a tap drill.

Threadedholesymbol

{"Diameter - Metric (D)":["6","8","10","12"],"Number of Flutes":"6","Corner Radius - Metric (R)":["0.5","1"],"Overall Length - Metric (L)":["50","60","70","75"],"Cutting Diameter Tolerance - Metric":"+0 / -0.020","Shank Diameter - Metric (d)":["6","8","10","12"],"Length of Cut - Metric (Lc)":["13","19","22","26"],"Stainless Steels : 17-4PH":"M; Good","Helix Angle - Degree":"45","Web Literature 4":"800388CA","Stainless Steels : 300":"M; Good","Brand":"EXOCARB","Web Literature 1":"8002024CA-EM,230|8002024CA-EMT,39","Hardened Steels : 35 HRC":"H; Best","Hardened Steels : 35-45 HRC":"H; Best","Alloy Steels : 4140; 4340":"P; Best","Hardened Steels : 45-50 HRC":"H; Best","Hardened Steels : 50-70 HRC":"H; Best","Substrate":"Carbide","Die Steels":"P; Best","Cast Iron":"K; Best","High Carbon Steel : 1065":"P; Best","Cutting Type":"Center Cutting","Low Carbon Steel : 1010; 1018":"P; Best","Medium Carbon Steel : 1035; 1045":"P; Best","End Cut Type":"Corner Radius","Shank Tolerance":"h6","View Catalog Page":"Here","View Speed and Feed Page":"Here","Coolant Thru":"No","Stainless Steels : 400":"M; Good","List Name":"MAX HARD-EMS","Full Description":"Maximum Performance Carbide End Mills for Hardened Steels over 55Rc","Short Description":"Maximum Performance Carbide End Mills for Hardened Steels over 55Rc","Units":"Metric","Product Overview":"Multiple Flute, Coner Radius, WXS Coating","Weldon Flat":"No","Surface Treatment":"WXS","Mill Type":"Single End","Length of Cut - Specification":"REGULAR","Cutting Direction":"RH","Helix Direction":"RH","Nickel Alloy : Inconel":"S; Good","Titanium : 6AL4V (30HRC)":"S; Good","Diameter-Sizes":"6mm - 12mm","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"50mm - 75mm","Shank-Sizes":"6mm - 12mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%209144/End_Mills_-_End_Mill_-_EXOCARB_MAX_-_List_9144_-_Catalog"],"Friendly Name":"9144"}

{"Overall Length - Inch (L)":["3.5","4","4.75","5.5","6"],"Number of Flutes":"5","Corner Radius - Inch (R)":["0.03","0.06","0.09","0.12","0.15"],"Neck Diameter - Inch (d1)":["0.48","0.605","0.73","0.98","1.23"],"Cutting Diameter Tolerance - Inch":"+0 / -0.002","Neck Length - Inch (L1)":["1.5","1.875","2.25","3","3.75"],"Diameter - Fractional Size (D)":["1/2","5/8","3/4","1","1-1/4"],"Diameter - Inch (D)":["0.5","0.625","0.75","1","1.25"],"Length of Cut - Inch (Lc)":["1","1.25","1.5","2","2.5"],"Shank Diameter - Inch (d)":["0.5","0.625","0.75","1","1.25"],"Stainless Steels : 300":"M; Good","Helix Angle - Degree":"41-42-43","Surface Treatment":"EXO","Brand":"EXOCARB","Stainless Steels : 400":"M; Good","Benefit 2":"For efficient milling and suppressed vibration","List Name":"AERO UVX-TI-LN-5FL","Benefit 4":"For increased rigidity and high efficient milling","Web Literature 1":"8002024CA-EM,241|8002024CA-EMT,40","Benefit 3":"For smooth chip evacuation","Benefit 1":"For stable, vibration-free milling","Substrate":"Carbide","Feature 3":"Ideal Flute Shape","Units":"Inch","Web Literature 4":"800388CA","Product Overview":"Carbide, EXO Coating, 5 Flute, Regular Length, Reduced Neck, Corner Radius","Cutting Type":"Center Cutting","Shank Tolerance":"h6","End Cut Type":"Corner Radius","Stainless Steels : 17-4PH":"M; Good","View Catalog Page":"Here","View Speed and Feed Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Type (feature)":"Reduced Neck","Length of Cut - Specification":"REGULAR","Cutting Direction":"RH","Helix Direction":"RH","Feature 1":"Unequal Spacing of End Teeth","Feature 2":"Variable Lead","Full Description":"Variable Lead End Mill for Titanium Alloy","Short Description":"Variable Lead End Mill for Titanium Alloy","Titanium : 6AL4V (30HRC)":"S; Best","Feature 4":"Web Taper","Diameter-Sizes":"1/2\" - 1.25\"","Flute-Sizes":"-","Neck-Sizes":"1.5\" - 3.75\"","Taper-Sizes":"-","Overall-Sizes":"3.5\" - 6\"","Shank-Sizes":"0.5\" - 1.25\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202108/End_Mills_-_End_Mill_-_List_2108_-_EXOCARB_AERO_UVX-Ti_-_Reduced_Neck_Corner_Radius_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202108/End_Mills_-_End_Mill_-_List_2108_-_EXOCARB_AERO_UVX-Ti_-_Action_4","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202108/End_Mills_-_End_Mill_-_List_2108_-_EXOCARB_AERO_UVX-Ti_-_Action_7"],"Friendly Name":"2108"}

{"Number of Flutes":"4","Overall Length - Inch (L)":["4","1.5","2","2.5","3","3.5"],"Shank Diameter - Inch (d)":["1","0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75"],"Corner Radius - Inch (R)":["0.125","0.02","0.03","0.045","0.06","0.09","0.015"],"Cutting Diameter Tolerance - Inch":"+0 / -0.002","Diameter - Fractional Size (D)":["1","1/8","3/16","1/4","5/16","3/8","1/2","5/8","3/4"],"Diameter - Inch (D)":["1","0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75"],"Helix Angle - Degree":"30","Length of Cut - Inch (Lc)":["1.5","0.5","0.625","0.75","0.8125","1","1.25"],"Product Overview":"4 Flute, Corner Radius","Web Literature 4":"800388CA","Stainless Steels : 300":"M; Good","Brand":"OSG","Web Literature 1":"8002024CA-EM,257|8002024CA-EMT,68","Notes":"Other coatings available upon request.","Surface Treatment":["BRIGHT","TiAlN"],"Units":"Inch","Substrate":"Carbide","Hardened Steels : 35 HRC":"H; Good","Hardened Steels : 35-45 HRC":"H; Good","Cutting Type":"Center Cutting","Cast Iron":"K; Good","Hardened Steels : 45-50 HRC":"H; Good","Hardened Steels : 50-70 HRC":"H; Good","End Cut Type":"Corner Radius","Alloy Steels : 4140; 4340":"P; Good","Die Steels":"P; Good","High Carbon Steel : 1065":"P; Good","Low Carbon Steel : 1010; 1018":"P; Good","View Catalog Page":"Here","View Speed and Feed Page":"Here","Stainless Steels : 400":"M; Good","Aluminum : Casting":"N; Good","Weldon Flat":"No","Coolant Thru":"No","Aluminum : 6061; 7075":"N; Good","Medium Carbon Steel : 1035; 1045":"P; Good","Mill Type":"Single End","List Name":"STANDARD CARBIDE CR","Full Description":"Standard Carbide End Mills for General Milling Applications","Short Description":"Standard Carbide End Mills for General Milling Applications","Cutting Direction":"RH","Length of Cut - Specification":["STUB","LONG","REGULAR"],"Helix Direction":"RH","Diameter-Sizes":"1/8\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"1.5\" - 4\"","Shank-Sizes":"0.125\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%20496/End_Mills_-_End_Mill_-_Carbide_-_List_496_-_Standard_Square_Corner_Radius_-_Catalog"],"Friendly Name":"496"}

{"Number of Flutes":"4","Corner Radius - Inch (R)":["0.03","0.06","0.125","0.19"],"Diameter - Inch (D)":["0.25","0.375","0.5","0.625","0.75","1"],"Diameter - Fractional Size (D)":["1/4","3/8","1/2","5/8","3/4","1"],"Length of Cut - Inch (Lc)":["0.375","0.75","0.5","0.875","0.625","1.25","1.5","2.25"],"Shank Diameter - Inch (d)":["0.25","0.375","0.5","0.625","0.75","1"],"Overall Length - Inch (L)":["2","2.5","3","3.5","4","5"],"Helix Angle - Degree":"40","Product Overview":"4-Flute, Roughing, Corner Radius, Multiple Lengths, TiAlN","Brand":"EXOCARB","List Name":"AERO ROUGHER","Web Literature 1":"8002024CA-EM,239|8002024CA-EMT,118","Hardened Steels : 35 HRC":"H; Best","Substrate":"Carbide","Alloy Steels : 4140; 4340":"P; Best","Units":"Inch","Web Literature 4":"800388CA","Die Steels":"P; Best","Hardened Steels : 35-45 HRC":"H; Good","High Carbon Steel : 1065":"P; Best","Cutting Type":"Center Cutting","Cast Iron":"K; Good","Low Carbon Steel : 1010; 1018":"P; Best","Medium Carbon Steel : 1035; 1045":"P; Best","Shank Tolerance":"h6","Stainless Steels : 17-4PH":"M; Best","End Cut Type":"Corner Radius","Stainless Steels : 300":"M; Best","Stainless Steels : 400":"M; Best","View Catalog Page":"Here","View Speed and Feed Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Full Description":"Performance Carbide Roughing End Mill for Stainless, Titanium and Ni-Alloys","Short Description":"Performance Carbide Roughing End Mill for Stainless, Titanium and Ni-Alloys","Cutting Direction":"RH","Length of Cut - Specification":["STUB","REGULAR"],"Helix Direction":"RH","Surface Treatment":"TiAlN","Cutting Diameter Tolerance - Inch":"+0 / -0.0015","Type (feature)":"Roughing","Nickel Alloy : Inconel":"S; Best","Titanium : 6AL4V (30HRC)":"S; Best","Diameter-Sizes":"1/4\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"2\" - 5\"","Shank-Sizes":"0.25\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%202015/End_Mills_-_End_Mill_-_EXOCARB_AERO_ROUGHER_-_List_2015_-_Catalog"],"Friendly Name":"2015"}

{"Diameter - Metric (D)":["3","4","5","6","8","10","12"],"Length of Cut - Metric (Lc)":["5","6","8","9","12","15","18"],"Number of Flutes":"4","Corner Radius - Metric (R)":["0.2","0.5","1","2"],"Neck Diameter - Metric (d1)":["2.85","3.8","4.8","5.8","7.7","9.7","11.7"],"Overall Length - Metric (L)":["60","70","80","90","100","110","120","130"],"Cutting Diameter Tolerance - Metric":"+0 / -0.020","Shank Diameter - Metric (d)":["6","8","10","12"],"Neck Length - Metric (L1)":["9","15","12","20","25","18","30","24","40","50","36","60"],"Web Literature 4":"800388CA","Product Overview":"4 Flute, Regular Length, Corner Radius, WXS","Feature 2":"High Precision geometry - All corner radius & ball mills have +/-5um radius tolerance","Helix Angle - Degree":"45","Stainless Steels : 300":"M; Good","Feature 3":"High strength core diameter","Benefit 4":"Higher coating oxidation temp & hardness dramatically improve wear resistance.","Brand":"EXOCARB","Stainless Steels : 400":"M; Good","Web Literature 1":"8002024CA-EM,222|8002024CA-EMT,107","Web Video 2":"https://youtu.be/dNdGq78-DvA","Web Video 1":"https://youtu.be/gJImj11Ubbg","Hardened Steels : 35 HRC":"H; Best","Web Literature 2":"800304CA","Hardened Steels : 35-45 HRC":"H; Best","Alloy Steels : 4140; 4340":"P; Best","Hardened Steels : 45-50 HRC":"H; Best","Substrate":"Carbide","Hardened Steels : 50-70 HRC":"H; Best","Die Steels":"P; Best","Cast Iron":"K; Best","High Carbon Steel : 1065":"P; Best","Cutting Type":"Center Cutting","Low Carbon Steel : 1010; 1018":"P; Best","Medium Carbon Steel : 1035; 1045":"P; Best","End Cut Type":"Corner Radius","Shank Tolerance":"h6","Benefit 2":"High accuracy all but eliminates need for benching and rework for mold makers.","Stainless Steels : 17-4PH":"M; Good","View Catalog Page":"Here","View Speed and Feed Page":"Here","Units":"Metric","Weldon Flat":"No","Coolant Thru":"No","Surface Treatment":"WXS","Feature 4":"WXS coating - +1300 Celsius Oxidation Temp. & +3500Hv in hardness","List Name":"WXS-PKE","Mill Type":"Single End","Full Description":"Premium High Performance Carbide End Mills for Hardened Steels","Short Description":"Premium High Performance Carbide End Mills for Hardened Steels","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Benefit 1":"The hardest most wear resistant carbide possible for incredible wear resistance.","Helix Direction":"RH","Benefit 3":"Tools utilize thicker core diameters for the ultimate in strength and rigidity.","Feature 1":"Ultra-fine micrograin carbide","Nickel Alloy : Inconel":"S; Good","Titanium : 6AL4V (30HRC)":"S; Good","Diameter-Sizes":"3mm - 12mm","Flute-Sizes":"-","Neck-Sizes":"9mm - 60mm","Taper-Sizes":"-","Overall-Sizes":"60mm - 130mm","Shank-Sizes":"6mm - 12mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%204571/End_Mills_-_End_Mill_-_EXOCARB_WXS_-_List_4571_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%204571/End_Mills_-_End_Mill_-_EXOCARB_WXS_-_List_4571_-_Extra_1"],"Friendly Name":"4571"}

{"Number of Flutes":"7","Cutting Diameter Tolerance - Inch":"+0 / -0.0015","Diameter - Inch (D)":["0.25","0.3125","0.375","0.5","0.625","0.75","1"],"Diameter - Fractional Size (D)":["1/4","5/16","3/8","1/2","5/8","3/4","1"],"L/D Ratio":["1.5","2","3","4","5","6","1.25","2.5"],"Length of Cut - Inch (Lc)":["0.375","0.5","0.75","1","1.25","1.5","0.46875","0.625","0.9375","0.5625","1.125","2","0.78125","1.5625","1.875","2.5","2.25","3"],"Shank Diameter - Inch (d)":["0.25","0.3125","0.375","0.5","0.625","0.75","1"],"Overall Length - Inch (L)":["2","2.5","3","4","3.5","5","6"],"Helix Angle - Degree":"36","Surface Treatment":"EXO","Web Literature 4":"800388CA","Feature 3":"EXO Coating","Web Literature 3":"800395CA|800386CA|800383CA|800367CA|80071CA|80070CA|80063CA","Product Overview":"7-Flute, Square & Corner Radius, Multiple Lengths","Web Literature 1":["8002024CA-EM,115|8002024CA-EMT,58","8002024CA-EM,116|8002024CA-EMT,58","8002024CA-EM,117|8002024CA-EMT,58"],"Web Video 1":"https://youtu.be/Brdsf6TH6yk","Benefit 3":"OSG’s proprietary multi-layer coating provides longer tool life through higher wear and heat resistance than conventional TiAlN coatings","Web Video 2":"https://youtu.be/owr-tCmQVEY","Hardened Steels : 35 HRC":"H; Best","Brand":"HY-PRO CARB","Web Literature 2":"800317CA-V7","Alloy Steels : 4140; 4340":"P; Best","Units":"Inch","Substrate":"Carbide","Die Steels":"P; Best","Cast Iron":"K; Best","High Carbon Steel : 1065":"P; Best","Hardened Steels : 35-45 HRC":"H; Good","Low Carbon Steel : 1010; 1018":"P; Best","Medium Carbon Steel : 1035; 1045":"P; Best","Stainless Steels : 17-4PH":"M; Best","Shank Tolerance":"h6","Stainless Steels : 300":"M; Best","Stainless Steels : 400":"M; Best","Short Description":"High Performance Variable Geometry End Mills","View Speed and Feed Page":"Here","View Catalog Page":"Here","Coolant Thru":"No","Weldon Flat":"No","Cutting Type":"Non-Center Cutting","Benefit 2":"Sharp rake angle, high helix and adjusted core diameter maintain excellent cutting edge sharpness and tool rigidity to promote smooth, stable cutting with low cutting force","Mill Type":"Single End","End Cut Type":["Square End","Corner Radius"],"Length of Cut - Specification":["STUB","REGULAR","LONG","EXTRA LONG"],"Cutting Direction":"RH","Full Description":"The HY-PRO CARB VGM end mill is a series of Variable Geometry end mills for Dynamic Milling, ideal in a wide range of Steels and Stainless steels.","Benefit 1":"Unequal flute spacing reduces vibration during machining by altering the timing of each flute engaging in the workpiece","Helix Direction":"RH","Feature 2":"Unique Flute Geometry","Feature 1":"Variable Index","Nickel Alloy : Inconel":"S; Best","List Name":"VGM7","Titanium : 6AL4V (30HRC)":"S; Best","Corner Radius - Inch (R)":["0.02","0.03","0.06"],"Diameter-Sizes":"1/4\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"2\" - 6\"","Shank-Sizes":"0.25\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM7/End_Mill_-_HY-PRO_CARB_VGM_-_VGM7_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM7/End_Mill_-_HY-PRO_CARB_VGM_-_VGM7_-_Face","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM7/End_Mill_-_HY-PRO_CARB_VGM_-_VGM7_-_Web_Product_Overview_1"],"Friendly Name":"VGM7"}

{"Overall Length - Inch (L)":["3","3.5","4"],"Number of Flutes":["6","8"],"Corner Radius - Inch (R)":["0.03125","0.0625","0.046875","0.09375","0.125"],"Diameter - Inch (D)":["0.25","0.3125","0.375","0.5"],"Diameter - Fractional Size (D)":["1/4","5/16","3/8","1/2"],"Length of Cut - Inch (Lc)":["0.375","0.46875","0.5625","0.75"],"Shank Diameter - Inch (d)":["0.25","0.3125","0.375","0.5"],"Web Literature 4":"800388CA","Surface Treatment":"DUROREY","Benefit 1":"enables superior heat resistance and high toughness optimized for high-hardness steel milling!","Stainless Steels : 300":"M; Good","Helix Angle - Degree":"60","Brand":"EXOCARB","Web Literature 1":"8002024CA-EM,227|8002024CA-EMT,112","List Name":"AM-CRE","Web Video 1":"https://youtu.be/rMW62-Jz2Ho","Web Literature 2":"800316CA-V2","Hardened Steels : 35-45 HRC":"H; Best","Hardened Steels : 45-50 HRC":"H; Best","Units":"Inch","Substrate":"Carbide","Full Description":"Carbide End Mills Designed for Additive Manufacturing","Short Description":"Carbide End Mills Designed for Additive Manufacturing","Product Overview":"Carbide, Durorey Coating, Multi-Flute, Inch Sizes","Hardened Steels : 50-70 HRC":"H; Good","Shank Tolerance":"h4","End Cut Type":"Corner Radius","Stainless Steels : 17-4PH":"M; Good","View Catalog Page":"Here","View Speed and Feed Page":"Here","Stainless Steels : 400":"M; Good","Feature 1":"Newly developed DUROREY coating","Weldon Flat":"No","Coolant Thru":"No","Cutting Type":"Non-Center Cutting","Mill Type":"Single End","Feature 2":"Radius Type (6-Flute/8-Flute)","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Benefit 2":"Suitable for milling of built-up welding parts","Helix Direction":"RH","Cutting Diameter Tolerance - Inch":"+/- 0.0004","Nickel Alloy : Inconel":"S; Best","Titanium : 6AL4V (30HRC)":"S; Best","Diameter-Sizes":"1/4\" - 0.5\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"3\" - 4\"","Shank-Sizes":"0.25\" - 0.5\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%204670/End_Mills_-_End_Mill-_EXOCARB_AM-CRE_-_List_4670_-_Catalog"],"Friendly Name":"4670"}

{"Number of Flutes":"2","Overall Length - Inch (L)":["4","6"],"Neck Diameter - Inch (d1)":["0.246","0.496","0.621","0.746","0.992"],"Cutting Diameter Tolerance - Inch":"+0 / -0.002","Diameter - Inch (D)":["0.25","0.5","0.625","0.75","1"],"Neck Length - Inch (L1)":["2.125","2.375","2.5","3.375"],"Diameter - Fractional Size (D)":["1/4","1/2","5/8","3/4","1"],"Product Overview":"2-Flute, Reduced Neck, Long Length, Square & Corner Radius, Bright","Benefit 4":"3 - 5 times tool life","Length of Cut - Inch (Lc)":["0.25","0.5","0.625","0.75","1"],"Shank Diameter - Inch (d)":["0.25","0.5","0.625","0.75","1"],"Helix Angle - Degree":"30","Benefit 2":"Enhances tool life by reducing BUE","Brand":"EXOCARB","List Name":"AERO BLIZZARD","Surface Treatment":"BRIGHT","Web Literature 1":"8002024CA-EM,87|8002024CA-EMT,45","Substrate":"Carbide","Benefit 3":"Ideal for rough and finish contouring","Units":"Inch","Web Literature 4":"800388CA","Cutting Type":"Center Cutting","Benefit 1":"Larger depth of cut and maximum feed per tooth","Shank Tolerance":"h6","Feature 3":"DLC available on request","Notes":"DLC coating available upon request.","View Speed and Feed Page":"Here","View Catalog Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Aluminum : 6061; 7075":"N; Best","Aluminum : Casting":"N; Best","Mill Type":"Single End","Full Description":"Performance Carbide End Mills For Aluminum","Short Description":"Performance Carbide End Mills For Aluminum","Type (feature)":"Reduced Neck","End Cut Type":["Square End","Corner Radius"],"Feature 1":"Refined geometry","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Helix Direction":"RH","Feature 2":"Ultra smooth Flutes","Corner Radius - Inch (R)":["0.02","0.03","0.06","0.09","0.12"],"Diameter-Sizes":"1/4\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"2.125\" - 3.375\"","Taper-Sizes":"-","Overall-Sizes":"4\" - 6\"","Shank-Sizes":"0.25\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202024/End_Mills_-_End_Mill_-_EXOCARB_AERO_Blizzard_-_List_2024_-_Catalog"],"Friendly Name":"2024"}

Both tapping and drilling can be used to join 2 pieces of metal together. But they are different ways of doing it! That’s why it’s good to understand them both!

{"Number of Flutes":"5","Diameter - Inch (D)":["0.125","0.15625","0.1875","0.21875","0.25","0.28125","0.3125","0.375","0.5","0.625","0.75","1"],"Diameter - Fractional Size (D)":["1/8","5/32","3/16","7/32","1/4","9/32","5/16","3/8","1/2","5/8","3/4","1"],"Shank Diameter - Inch (d)":["0.125","0.15625","0.1875","0.21875","0.25","0.3125","0.375","0.5","0.625","0.75","1"],"L/D Ratio":["1.5","2","3","4","5","6","1.25","2.5"],"Length of Cut - Inch (Lc)":["0.1875","0.25","0.375","0.5","0.625","0.75","0.234375","0.3125","0.46875","0.28125","0.5625","0.9375","0.328125","0.4375","1","1.25","1.5","0.421875","0.84375","1.125","2","2.5","0.78125","1.5625","1.875","2.25","3","3.75","4"],"Overall Length - Inch (L)":["1.5","2.25","2","2.5","3","4","5","3.5","6","7"],"Helix Angle - Degree":"40","Surface Treatment":"EXO","Feature 3":"EXO Coating","Web Literature 4":"800388CA","Web Literature 3":"800395CA|800386CA|800383CA|800367CA|80071CA|80070CA|80063CA","Product Overview":"5-Flute, Square & Corner Radius, Multiple Lengths","Web Literature 1":["8002024CA-EM,103|8002024CA-EMT,55","8002024CA-EM,104|8002024CA-EMT,55","8002024CA-EM,105|8002024CA-EMT,55","8002024CA-EM,106|8002024CA-EMT,55","8002024CA-EM,107|8002024CA-EMT,55","8002024CA-EM,108|8002024CA-EMT,55"],"Web Video 1":"https://youtu.be/Brdsf6TH6yk","Benefit 3":"OSG’s proprietary multi-layer coating provides longer tool life through higher wear and heat resistance than conventional TiAlN coatings","Web Video 2":"https://youtu.be/owr-tCmQVEY","Hardened Steels : 35 HRC":"H; Best","Brand":"HY-PRO CARB","Web Literature 2":"800317CA-V7","Alloy Steels : 4140; 4340":"P; Best","Units":"Inch","Substrate":"Carbide","Die Steels":"P; Best","Cast Iron":"K; Best","High Carbon Steel : 1065":"P; Best","Hardened Steels : 35-45 HRC":"H; Good","Low Carbon Steel : 1010; 1018":"P; Best","Cutting Type":"Center Cutting","Medium Carbon Steel : 1035; 1045":"P; Best","Stainless Steels : 17-4PH":"M; Best","Shank Tolerance":"h6","Stainless Steels : 300":"M; Best","Stainless Steels : 400":"M; Best","Short Description":"High Performance Variable Geometry End Mills","View Speed and Feed Page":"Here","View Catalog Page":"Here","Coolant Thru":"No","Weldon Flat":["No","Yes"],"Mill Type":"Single End","End Cut Type":["Square End","Corner Radius"],"Length of Cut - Specification":["STUB","REGULAR","LONG","EXTRA LONG"],"Cutting Direction":"RH","Full Description":"The HY-PRO CARB VGM end mill is a series of Variable Geometry end mills for Dynamic Milling, ideal in a wide range of Steels and Stainless steels.","Cutting Diameter Tolerance - Inch":"+0 / -0.0015","Benefit 1":"Unequal flute spacing reduces vibration during machining by altering the timing of each flute engaging in the workpiece","Helix Direction":"RH","Feature 2":"Unique Flute Geometry","Feature 1":"Variable Index","Nickel Alloy : Inconel":"S; Best","List Name":"VGM5","Titanium : 6AL4V (30HRC)":"S; Best","Benefit 2":"Sharp rake angle, high helix and adjusted core diameter maintain excellent cutting edge sharpness and tool rigidity to promote smooth, stable cutting with low cutting force","Corner Radius - Inch (R)":["0.01","0.015","0.03","0.02","0.06","0.09","0.12","0.125","0.19","0.25"],"Diameter-Sizes":"1/8\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"1.5\" - 7\"","Shank-Sizes":"0.125\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM5/End_Mill_-_HY-PRO_CARB_VGM_-_VGM5_-_Catalog"],"Friendly Name":"VGM5"}

{"Number of Flutes":"2","Corner Radius - Metric (R)":["0.05","0.1","0.2","0.3","0.5"],"Neck Diameter - Metric (d1)":["0.37","0.46","0.56","0.76","0.95","1.15","1.45","1.95","2.4","2.85","0.94"],"Overall Length - Metric (L)":["50","60","70","80"],"Shank Diameter - Metric (d)":["4","6"],"Cutting Diameter Tolerance - Metric":["+0 / -0.010","+0 / -0.015"],"Neck Length - Metric (L1)":["2","3","4","1","5","6","8","10","12","16","20","25","30","35"],"Product Overview":"2 Flute, Corner Radius, Stub Length, Long Neck, Rib Processing, WXS","Diameter - Metric (D)":["0.4","0.5","0.6","0.8","1","1.2","1.5","2","2.5","3"],"Helix Angle - Degree":"30","Web Literature 4":"800388CA","Length of Cut - Metric (Lc)":["0.3","0.4","0.48","0.65","0.8","1","1.2","1.6","2.2","2.5"],"Feature 2":"High Precision geometry - All corner radius & ball mills have +/-5um radius tolerance","Feature 3":"High strength core diameter","Benefit 4":"Higher coating oxidation temp & hardness dramatically improve wear resistance.","Brand":"EXOCARB","Web Literature 1":["8002024CA-EM,218|8002024CA-EMT,105","8002024CA-EM,219|8002024CA-EMT,105","8002024CA-EM,220|8002024CA-EMT,105"],"Web Video 2":"https://youtu.be/dNdGq78-DvA","Hardened Steels : 35 HRC":"H; Best","Web Video 1":"https://youtu.be/gJImj11Ubbg","Hardened Steels : 35-45 HRC":"H; Best","Web Literature 2":"800304CA|800291CA","Alloy Steels : 4140; 4340":"P; Best","Substrate":"Carbide","Hardened Steels : 45-50 HRC":"H; Best","Hardened Steels : 50-70 HRC":"H; Best","Die Steels":"P; Best","High Carbon Steel : 1065":"P; Best","Cutting Type":"Center Cutting","Low Carbon Steel : 1010; 1018":"P; Best","Medium Carbon Steel : 1035; 1045":"P; Best","Type (feature)":"Long Neck","Stainless Steels : 17-4PH":"M; Best","End Cut Type":"Corner Radius","Shank Tolerance":"h6","Stainless Steels : 300":"M; Best","Benefit 2":"High accuracy all but eliminates need for benching and rework for mold makers.","Stainless Steels : 400":"M; Best","View Catalog Page":"Here","View Speed and Feed Page":"Here","Units":"Metric","Weldon Flat":"No","Coolant Thru":"No","Surface Treatment":"WXS","Feature 4":"WXS coating - +1300 Celsius Oxidation Temp. & +3500Hv in hardness","List Name":"WXS-CPR","Mill Type":"Single End","Full Description":"Premium High Performance Carbide End Mills for Hardened Steels","Short Description":"Premium High Performance Carbide End Mills for Hardened Steels","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Benefit 1":"The hardest most wear resistant carbide possible for incredible wear resistance.","Helix Direction":"RH","Benefit 3":"Tools utilize thicker core diameters for the ultimate in strength and rigidity.","Radius Tolerance - Metric":"+/- 0.005","Feature 1":"Ultra-fine micrograin carbide","Diameter-Sizes":"0.4mm - 3mm","Flute-Sizes":"-","Neck-Sizes":"1mm - 35mm","Taper-Sizes":"-","Overall-Sizes":"50mm - 80mm","Shank-Sizes":"4mm - 6mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%204592/End_Mills_-_End_Mill_-_EXOCARB_WXS_-_List_4592_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%204592/End_Mills_-_End_Mill_-_EXOCARB_WXS_-_List_4592_-_Type_1","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%204592/End_Mills_-_End_Mill_-_EXOCARB_WXS_-_List_4592_-_IM"],"Friendly Name":"4592"}

{"Number of Flutes":"7","Cutting Diameter Tolerance - Inch":"+0 / -0.0015","Diameter - Inch (D)":["0.25","0.3125","0.375","0.5","0.625","0.75","1"],"Diameter - Fractional Size (D)":["1/4","5/16","3/8","1/2","5/8","3/4","1"],"L/D Ratio":["3","4","5","6","2","2.5","1.25","1.5"],"Shank Diameter - Inch (d)":["0.25","0.3125","0.375","0.5","0.625","0.75","1"],"Length of Cut - Inch (Lc)":["0.75","1","1.25","1.5","0.9375","1.125","2","0.78125","1.5625","1.875","2.5","2.25","3"],"Overall Length - Inch (L)":["2.5","3","4","3.5","5","6"],"Helix Angle - Degree":"36","Surface Treatment":"EXO","Feature 3":"EXO Coating","Product Overview":"7-Flute, Square & Corner Radius, Multiple Lengths, Nicked","Benefit 3":"OSG’s proprietary multi-layer coating provides longer tool life through higher wear and heat resistance than conventional TiAlN coatings","Hardened Steels : 35 HRC":"H; Best","Brand":"HY-PRO CARB","Alloy Steels : 4140; 4340":"P; Best","Units":"Inch","Substrate":"Carbide","Die Steels":"P; Best","Cast Iron":"K; Best","High Carbon Steel : 1065":"P; Best","Hardened Steels : 35-45 HRC":"H; Good","Low Carbon Steel : 1010; 1018":"P; Best","Medium Carbon Steel : 1035; 1045":"P; Best","Stainless Steels : 17-4PH":"M; Best","Shank Tolerance":"h6","Stainless Steels : 300":"M; Best","Stainless Steels : 400":"M; Best","Short Description":"High Performance Variable Geometry End Mills","Coolant Thru":"No","Weldon Flat":"No","Cutting Type":"Non-Center Cutting","Benefit 2":"Sharp rake angle, high helix and adjusted core diameter maintain excellent cutting edge sharpness and tool rigidity to promote smooth, stable cutting with low cutting force","Mill Type":"Single End","End Cut Type":["Square End","Corner Radius"],"Length of Cut - Specification":["REGULAR","LONG","EXTRA LONG","STUB"],"Cutting Direction":"RH","Full Description":"The HY-PRO CARB VGM end mill is a series of Variable Geometry end mills for Dynamic Milling, ideal in a wide range of Steels and Stainless steels.","Benefit 1":"Unequal flute spacing reduces vibration during machining by altering the timing of each flute engaging in the workpiece","Helix Direction":"RH","Feature 2":"Unique Flute Geometry","Feature 1":"Variable Index","Nickel Alloy : Inconel":"S; Best","List Name":"VGM7-NIK","Titanium : 6AL4V (30HRC)":"S; Best","Corner Radius - Inch (R)":["0.02","0.03","0.06"],"Diameter-Sizes":"1/4\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"2.5\" - 6\"","Shank-Sizes":"0.25\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM7-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM7-NIK_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM7-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM7-NIK_-_Angle","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM7-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM7-NIK_-_Face"],"Friendly Name":"VGM7-NIK"}

{"Number of Flutes":"4","Corner Radius - Inch (R)":["0.01","0.015","0.02","0.03","0.06"],"Diameter - Inch (D)":["0.046875","0.0625","0.09375","0.125","0.1875","0.25","0.375","0.5"],"Shank Diameter - Inch (d)":["0.125","0.1875","0.25","0.375","0.5"],"Length of Cut - Inch (Lc)":["0.234375","0.3125","0.46875","0.625","0.9375","1.25","1.875","2.25"],"Diameter - Fractional Size (D)":["3/64","1/16","3/32","1/8","3/16","1/4","3/8","1/2"],"Overall Length - Inch (L)":["2.5","3","4","6"],"Helix Angle - Degree":"30","Web Literature 4":"800388CA","Brand":"EXOCARB","Web Literature 1":"8002024CA-EM,249|8002024CA-EMT,121","Graphite":"Other; Best","Web Literature 2":"800369CA","Substrate":"Carbide","Units":"Inch","Product Overview":"Carbide, DG Coating, Inch Sizes","Cutting Type":"Center Cutting","Length of Cut - Specification":"LONG","Full Description":"Long Length of Cut DG Coated 4-Fluted Corner Radius Mills for Graphite","Short Description":"Long Length of Cut DG Coated 4-Fluted Corner Radius Mills for Graphite","Shank Tolerance":"h4","Benefit 1":"Low resistance to minimize the chipping of the work piece, Stable diamond crystals for milling graphite","End Cut Type":"Corner Radius","Surface Treatment":"DG","Feature 1":"DG Coating","List Name":"DG-CR-EML","View Catalog Page":"Here","View Speed and Feed Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Cutting Direction":"RH","Radius Tolerance - Inch":["+/- 0.00028","+/- 0.00039"],"Helix Direction":"RH","Diameter-Sizes":"3/64\" - 0.5\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"2.5\" - 6\"","Shank-Sizes":"0.125\" - 0.5\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%207470/End_Mills_-_End_Mill_-_EXOCARB_DG-CR-EML_-_List_7470","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%207470/OSG_-_Website_-_New_Products_-_DG-CR-EML"],"Friendly Name":"7470"}

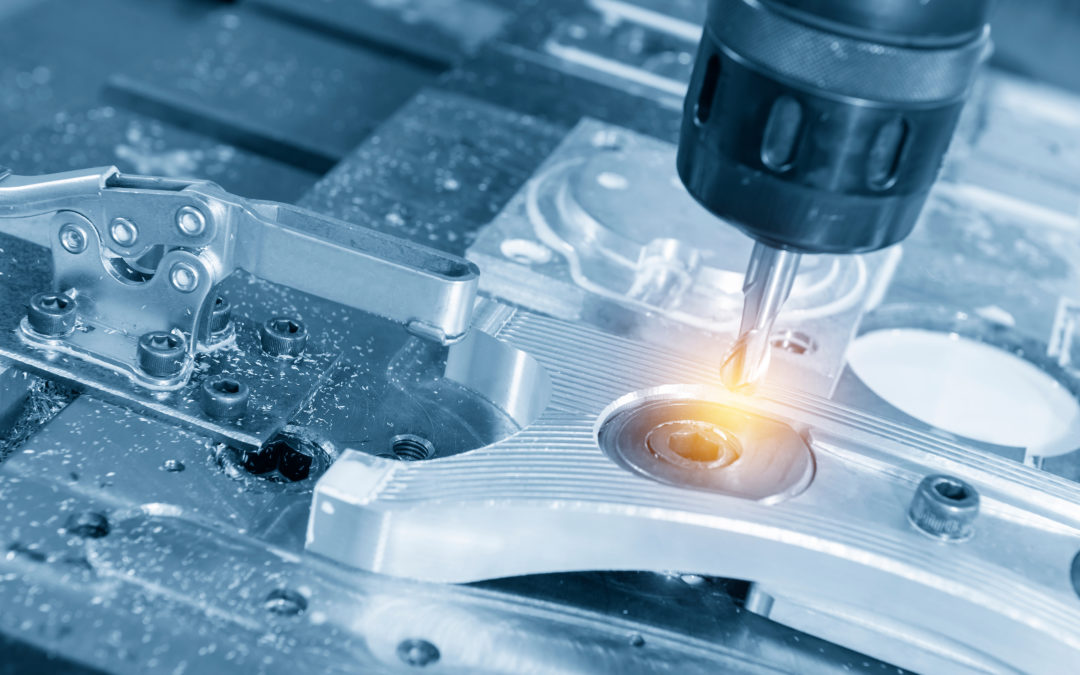

PartsBadger has state-of-the-art equipment like computer numerical control (CNC) mills, CNC lathes, laser cutters, water jet machines, die cast machines, sheet metal bending machines, 3D Printing, and more. This is the company that will give you the exact custom parts you need.

{"Bottom Edge Radius - Metric (R2)":["0.488","0.975","1.463","1.95","2.438","2.925","3.9","4.875","5.85"],"Number of Flutes":["4","5"],"Corner Radius - Metric (R)":["0.1","0.15","0.2","0.3"],"Neck Diameter - Metric (d1)":["0.85","1.8","2.7","3.6","4.5","5.4","7.2","9","11"],"Effective Diameter - Metric (DCF)":["0.36","0.73","1.1","1.5","1.87","2.24","2.99","3.83","4.59"],"Effective Neck Length by Incline Angle 0.5° - Metric":["3.16","6.29","9.36","12.42","15.5"],"Effective Neck Length by Incline Angle 1.5° - Metric":["3.5","6.82","10.04","13.3","16.59"],"Effective Neck Length by Incline Angle 1° - Metric":["3.33","6.56","9.7","12.85","16.02"],"Effective Neck Length by Incline Angle 2.5° - Metric":["4","7.63","11.22","14.87"],"Effective Neck Length by Incline Angle 2° - Metric":["3.66","7.07","10.4","13.78"],"Overall Length - Metric (L)":["50","60","70","80","90","100","110"],"Effective Radius - Metric (rt)":["0.1","0.2","0.3","0.35","0.4","0.45","0.65","0.7","0.8"],"Shank Diameter - Metric (d)":["6","8","10","12"],"Helix Angle - Degree":"0","Type":["1","2"],"Interference Angle - Degree (α)":["11.4","8.5","6","3.8000000000000003","1.8"],"Neck Length - Metric (L1)":["3","6","9","12","15","18","24","30","36"],"Feature 2":"2-Stage Gashing","Non-Taper Neck Length - Metric (L2)":["3","6","9","12","15","18","24","30","36"],"Diameter - Metric (D)":["1","2","3","4","5","6","8","10","12"],"Length of Cut - Metric (Lc)":["0.4","0.8","1.3","1.6","2","2.5","3.5","4.5","5"],"Surface Treatment":"DUROREY","Feature 4":"DUROREY Coating","Brand":"A Brand","Web Video 1":"https://www.youtube.com/watch?v=FSHlB8dkhrs","Short Description":"Advanced Performance Carbide End Mills with DUROREY Coating","Benefit 1":"Optimized for flat surface machining","List Name":"AE-HFE-H","Benefit 4":"Outstanding performance in high-hardness steels","Hardened Steels : 45-50 HRC":"H; Best","Hardened Steels : 50-70 HRC":"H; Best","Substrate":"Carbide","Benefit 2":"Increases cutting edge strength and improves chip evacuation","Product Overview":"Carbide, Durorey Coating, Metric Sizes","Hardened Steels : 35-45 HRC":"H; Good","Shank Tolerance":"h4","Feature 1":"Composite Radius Shape","Type (feature)":"High Feed","End Cut Type":"High Feed Radius","Units":"Metric","Weldon Flat":"No","Cutting Type":"Non-Center Cutting","Coolant Thru":"No","Mill Type":"Single End","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Benefit 3":"Suppresses chattering for stable machining of high-hardness steels","Full Description":"The OSG A-Brand AE-HFE-H is a carbide composite radius tool designed for high speed milling and efficient facing of hardened steels.","Radius Tolerance - Metric":["+/- 0.020","+/- 0.050"],"Feature 3":"Variable Indexing","Diameter-Sizes":"1mm - 12mm","Flute-Sizes":"-","Neck-Sizes":"3mm - 36mm","Taper-Sizes":"-","Overall-Sizes":"50mm - 110mm","Shank-Sizes":"6mm - 12mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%208571/End_Mills_-_End_Mill_-_A_Brand_AE-H_-_List_8571_-_AE-HFE-H_-_Type_1","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%208571/End_Mills_-_End_Mill_-_A_Brand_AE-H_-_List_8571_-_AE-HFE-H_-_Type_2"],"Friendly Name":"8571"}

{"Overall Length - Inch (L)":["3","4","6"],"Coating Thickness (µm)":"12","Number of Flutes":"4","Corner Radius - Inch (R)":["0.015","0.031","0.062","0.03"],"Neck Diameter - Inch (d1)":["0.119","0.178","0.238","0.356","0.475"],"Neck Length - Inch (L1)":["0.625","0.938","0.75","1.125","1.5"],"Diameter - Inch (D)":["0.125","0.1875","0.25","0.375","0.5"],"Cutting Diameter Tolerance - Inch":"+0 / -0.002","Diameter - Fractional Size (D)":["1/8","3/16","1/4","3/8","1/2"],"Shank Diameter - Inch (d)":["0.125","0.1875","0.25","0.375","0.5"],"Length of Cut - Inch (Lc)":["0.125","0.1875","0.25","0.375","0.5"],"Helix Angle - Degree":"30","Web Literature 4":"800388CA","Brand":"EXOCARB","Web Literature 1":"8002024CA-EM,247|8002024CA-EMT,49","Graphite":"Other; Best","Substrate":"Carbide","Units":"Inch","Cutting Type":"Center Cutting","Type (feature)":"Long Shank","End Cut Type":"Corner Radius","Shank Tolerance":"h6","Surface Treatment":"DIAMOND","List Name":"DIAMOND LS-CR","Full Description":"High Performance Diamond Coated Ball Mills for Graphite & Non-Ferrous Materials","Short Description":"High Performance Diamond Coated Ball Mills for Graphite & Non-Ferrous Materials","View Catalog Page":"Here","View Speed and Feed Page":"Here","Aluminum : 6061; 7075":"N; Best","Aluminum : Casting":"N; Best","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Product Overview":"Standard Series, Stub Length, 4 Flute, Long Shank, Corner Radius, OSG Diamond","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Helix Direction":"RH","Diameter-Sizes":"1/8\" - 0.5\"","Flute-Sizes":"-","Neck-Sizes":"0.625\" - 1.5\"","Taper-Sizes":"-","Overall-Sizes":"3\" - 6\"","Shank-Sizes":"0.125\" - 0.5\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%207072/End_Mills_-_End_Mill_-_EXOCARB_Diamond_-_List_7072_-_Catalog"],"Friendly Name":"7072"}

{"Overall Length - Inch (L)":["2.75","3.5","3.75","4","4.5"],"Number of Flutes":"4","Corner Radius - Inch (R)":["0.015","0.03","0.06","0.045","0.09"],"Diameter - Inch (D)":["0.25","0.3125","0.375","0.5"],"Diameter - Fractional Size (D)":["1/4","5/16","3/8","1/2"],"Shank Diameter - Inch (d)":["0.25","0.3125","0.375","0.5"],"Length of Cut - Inch (Lc)":["0.75","0.9375","1.125","1.5","1","1.25","2"],"Surface Treatment":"DUARISE","Feature 4":"Duarise Coating","Feature 2":"High Rigidity","Helix Angle - Degree":"42-44","Web Literature 4":"800388CA","Brand":"A Brand","Full Description":"Advanced Performance Anti-Vibration Carbide End Mills","Short Description":"Advanced Performance Anti-Vibration Carbide End Mills","List Name":"AE-CR-VML","Benefit 3":"Facilitates excellent chip evacuation","Web Literature 1":"8002024CA-EM,197|8002024CA-EMT,6","Web Video 2":"https://youtu.be/L2OILf73yQc","Hardened Steels : 35 HRC":"H; Best","Web Video 1":"https://youtu.be/rSQmoEyDRn0","Web Video 3":"https://youtu.be/siKW3ZaAcec","Web Literature 2":"800292CA-V5","Hardened Steels : 35-45 HRC":"H; Best","Benefit 2":"Improves milling accuracy","Alloy Steels : 4140; 4340":"P; Best","Substrate":"Carbide","Units":"Inch","Die Steels":"P; Best","Product Overview":"Carbide, DUR Coating, 4 Flute, Corner Radius, Long Lengths","Cast Iron":"K; Best","High Carbon Steel : 1065":"P; Best","Cutting Type":"Center Cutting","Low Carbon Steel : 1010; 1018":"P; Best","Hardened Steels : 45-50 HRC":"H; Good","Hardened Steels : 50-70 HRC":"H; Good","Medium Carbon Steel : 1035; 1045":"P; Best","End Cut Type":"Corner Radius","Stainless Steels : 17-4PH":"M; Best","Stainless Steels : 300":"M; Best","Stainless Steels : 400":"M; Best","View Catalog Page":"Here","View Speed and Feed Page":"Here","Aluminum : 6061; 7075":"N; Good","Aluminum : Casting":"N; Good","Feature 3":"New Flute Form","Benefit 4":"Minimizes thermal cracks","Weldon Flat":"No","Coolant Thru":"No","Shank Tolerance":"Shrink Fit","Feature 1":"Positive Rake Angle","Mill Type":"Single End","Benefit 1":"Reduces Cutting Force","Length of Cut - Specification":["REGULAR","LONG"],"Cutting Direction":"RH","Cutting Diameter Tolerance - Inch":"+0 / -0.0008","Helix Direction":"RH","Nickel Alloy : Inconel":"S; Good","Titanium : 6AL4V (30HRC)":"S; Good","Diameter-Sizes":"1/4\" - 0.5\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"2.75\" - 4.5\"","Shank-Sizes":"0.25\" - 0.5\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%208271/End_Mills_-_End_Mill_-_A_Brand_AE-VM_-_List_8271_-_AE-CR-VML_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%208271/OSG_-_Website_-_New_Products_-_AE-CR-VML"],"Friendly Name":"8271"}

{"Bottom Edge Radius - Metric (R2)":["2.5","3","3.5","5","6","7"],"Diameter - Metric (D)":["4","5","6","8","10","12"],"Length of Cut - Metric (Lc)":["8","10","12","16","20","24"],"Number of Flutes":"6","Corner Radius - Metric (R)":["0.4","0.5","0.6","0.8","1","1.2"],"Neck Diameter - Metric (d1)":["3.8","4.8","5.8","7.7","9.7","11.7"],"Effective Diameter - Metric (DCF)":["2","2.5","3","4","5","6"],"Effective Neck Length by Incline Angle 0.5° - Metric":["12.53","15.64"],"Effective Neck Length by Incline Angle 1.5° - Metric":["13.43","16.74"],"Effective Neck Length by Incline Angle 1° - Metric":["12.98","16.18"],"Overall Length - Metric (L)":["50","60","70","80","90"],"Effective Neck Length by Incline Angle 2° - Metric":"13.91","Effective Neck Length by Incline Angle 3° - Metric":"15","Effective Radius - Metric (rt)":["0.5","0.6","0.8","1","1.2","1.5"],"Shank Diameter - Metric (d)":["6","8","10","12"],"Type":["1","2"],"Neck Length - Metric (L1)":["15.9","17"],"Non-Taper Neck Length - Metric (L2)":["12","15","18","24","30","36"],"Interference Angle - Degree (α)":["3.73","1.76"],"Web Literature 4":"800388CA","Surface Treatment":"DUROREY","Feature 4":"DUROREY Coating","Helix Angle - Degree":"45","Brand":"EXOCARB","Web Video 3":"https://youtu.be/4YN7_KaZZjw","Benefit 1":"Optimized for flat surface machining","Benefit 4":"Optimized for high hardness steel machining","Web Video 2":"https://youtu.be/Aq7Gr_BUKls","Feature 3":"Flat cutting edge","Web Literature 1":"8002024CA-EM,229|8002024CA-EMT,113","List Name":"AM-HFC","Web Video 1":"https://youtu.be/V8c3rvJDd58","Web Literature 2":"800316CA-V2","Benefit 2":"Improves chip evacuation and prevents chip packing","Substrate":"Carbide","Hardened Steels : 45-50 HRC":"H; Best","Hardened Steels : 50-70 HRC":"H; Best","Full Description":"Carbide End Mills Designed for Additive Manufacturing","Short Description":"Carbide End Mills Designed for Additive Manufacturing","Product Overview":"Carbide, Durorey Coating, High Feed, Metric Sizes","Hardened Steels : 35-45 HRC":"H; Good","Feature 1":"Composite Radius Shape","Feature 2":"Coolant-through","Stainless Steels : 17-4PH":"M; Best","Stainless Steels : 300":"M; Best","Type (feature)":"High Feed","End Cut Type":"High Feed Radius","Stainless Steels : 400":"M; Best","View Catalog Page":"Here","View Speed and Feed Page":"Here","Units":"Metric","Weldon Flat":"No","Cutting Type":"Non-Center Cutting","Shank Tolerance":"Shrink Fit","Coolant Thru":"Yes","Mill Type":"Single End","Length of Cut - Specification":"REGULAR","Cutting Direction":"RH","Benefit 3":"Suppresses chipping and improves surface quality","Helix Direction":"RH","Cutting Diameter Tolerance - Metric":"+/- 0.010","Radius Tolerance - Metric":"+/- 0.030","Nickel Alloy : Inconel":"S; Best","Titanium : 6AL4V (30HRC)":"S; Best","Diameter-Sizes":"4mm - 12mm","Flute-Sizes":"-","Neck-Sizes":"15.9mm - 17mm","Taper-Sizes":"-","Overall-Sizes":"50mm - 90mm","Shank-Sizes":"6mm - 12mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%204970/End_Mills_-_End_Mill_-_EXOCARB_AM-HFC_-_List_4970_-_Catalog"],"Friendly Name":"4970"}

From prototyping to manufacturing, let PartsBadger take care of your manufacturing needs. We’re here to help answer any questions you might have about our manufacturing techniques to get your custom parts made.

Jul 27, 2021 — Rebar, or reinforcing bar, is a bar that's used to reinforce and strengthen concrete under tension. It's typically made of steel, ...

{"Number of Flutes":"2","Corner Radius - Metric (R)":["0.05","0.1","0.2","0.3","0.5"],"Overall Length - Metric (L)":["45","50"],"Shank Diameter - Metric (d)":["4","6"],"Cutting Diameter Tolerance - Metric":["+0 / -0.010","+0 / -0.015"],"Neck Length - Metric (L1)":["2.5","5","7.5","10","12"],"Diameter - Metric (D)":["0.5","1","1.5","2","3"],"Helix Angle - Degree":"30","Length of Cut - Metric (Lc)":["0.3","0.6","0.9","1.2","1.8"],"Web Literature 4":"800388CA","Feature 3":"5-micron radius tolerance","Brand":"EXOCARB","Benefit 3":"For finishing precision","Web Literature 1":"8002024CA-EM,232|8002024CA-EMT,116","Benefit 1":"Allows for greater depths of cut","Surface Treatment":"BRIGHT","Hardened Steels : 45-50 HRC":"H; Best","Hardened Steels : 50-70 HRC":"H; Best","Substrate":"CBN","Product Overview":"CBN, Finishing, 2-flute, Long Neck","Hardened Steels : 35-45 HRC":"H; Good","Cutting Type":"Center Cutting","Type (feature)":"Long Neck","End Cut Type":"Corner Radius","Shank Tolerance":"h6","View Catalog Page":"Here","View Speed and Feed Page":"Here","List Name":"MAX CBN-LN-SXR","Full Description":"Maximum Performance CBN Ball Mills for Hardened Steels over 55Rc","Short Description":"Maximum Performance CBN Ball Mills for Hardened Steels over 55Rc","Units":"Metric","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Feature 1":"Spiral gash","Benefit 2":"Reduces cutting friction","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Radius Tolerance - Metric":"+/- 0.005","Feature 2":"True ground ball with seamless tangency","Helix Direction":"RH","Diameter-Sizes":"0.5mm - 3mm","Flute-Sizes":"-","Neck-Sizes":"2.5mm - 12mm","Taper-Sizes":"-","Overall-Sizes":"45mm - 50mm","Shank-Sizes":"4mm - 6mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%209182/End_Mills_-_End_Mill_-_EXOCARB_MAX_-_List_9182_-_Catalog"],"Friendly Name":"9182"}

{"Number of Flutes":"2","Overall Length - Inch (L)":["4","1.5","2","2.5","3","3.5"],"Shank Diameter - Inch (d)":["1","0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75"],"Corner Radius - Inch (R)":["0.06","0.09","0.125","0.015","0.02","0.03"],"Diameter - Fractional Size (D)":["1","1/8","3/16","1/4","5/16","3/8","1/2","5/8","3/4"],"Product Overview":"2 or 4 Flute, Corner Radius, TiAlN","Diameter - Inch (D)":["1","0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75"],"Length of Cut - Inch (Lc)":["1.5","0.5","0.625","0.75","0.8125","1","1.25"],"Helix Angle - Degree":"35","Stainless Steels : 17-4PH":"M; Good","Web Literature 4":"800388CA","Stainless Steels : 300":"M; Good","Web Literature 1":"8002024CA-EM,255|8002024CA-EMT,123","Brand":"HY-PRO CARB","Units":["Inch","Metric"],"Substrate":"Carbide","Hardened Steels : 35 HRC":"H; Good","Hardened Steels : 35-45 HRC":"H; Good","Cast Iron":"K; Good","Cutting Type":"Center Cutting","Hardened Steels : 45-50 HRC":"H; Good","End Cut Type":"Corner Radius","List Name":"Cr","Shank Tolerance":"h6","Alloy Steels : 4140; 4340":"P; Good","Die Steels":"P; Good","High Carbon Steel : 1065":"P; Good","Low Carbon Steel : 1010; 1018":"P; Good","View Catalog Page":"Here","View Speed and Feed Page":"Here","Coolant Thru":"No","Stainless Steels : 400":"M; Good","Weldon Flat":"No","Medium Carbon Steel : 1035; 1045":"P; Good","Full Description":"Performance Carbide TiAlN End Mills for Ferrous and Non-Ferrous Materials","Short Description":"Performance Carbide TiAlN End Mills for Ferrous and Non-Ferrous Materials","Mill Type":"Single End","Length of Cut - Specification":["STUB","REGULAR","LONG"],"Cutting Direction":"RH","Surface Treatment":"TiAlN","Cutting Diameter Tolerance - Inch":"+0 / -0.0015","Helix Direction":"RH","Nickel Alloy : Inconel":"S; Good","Titanium : 6AL4V (30HRC)":"S; Good","Diameter - Metric (D)":["3","4","5","6","8","10","12"],"Length of Cut - Metric (Lc)":["8","11","13","19","22","26"],"Corner Radius - Metric (R)":["0.2","0.5","1","1.5","2","3"],"Overall Length - Metric (L)":["60","70","80","100","110"],"Cutting Diameter Tolerance - Metric":"+0 / -0.038","Shank Diameter - Metric (d)":["6","8","10","12"],"Diameter-Sizes":"3mm - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"1.5\" - 110mm","Shank-Sizes":"0.125\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%20HP432/End_Mills_-_End_Mill_-_HY-PRO_CARB_-_List_HP432_-_Corner_Radius_-_Catalog"],"Friendly Name":"HP432"}

{"Number of Flutes":"4","Overall Length - Inch (L)":["4","1.5","2","2.5","3","3.5"],"Shank Diameter - Inch (d)":["1","0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75"],"Corner Radius - Inch (R)":["0.06","0.09","0.125","0.015","0.02","0.03"],"Diameter - Fractional Size (D)":["1","1/8","3/16","1/4","5/16","3/8","1/2","5/8","3/4"],"Product Overview":"2 or 4 Flute, Corner Radius, TiAlN","Diameter - Inch (D)":["1","0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75"],"Length of Cut - Inch (Lc)":["1.5","0.5","0.625","0.75","0.8125","1","1.25"],"Helix Angle - Degree":"35","Stainless Steels : 17-4PH":"M; Good","Web Literature 4":"800388CA","Stainless Steels : 300":"M; Good","Web Literature 1":"8002024CA-EM,256|8002024CA-EMT,124","Brand":"HY-PRO CARB","Units":["Inch","Metric"],"Substrate":"Carbide","Hardened Steels : 35 HRC":"H; Good","Hardened Steels : 35-45 HRC":"H; Good","Cast Iron":"K; Good","Cutting Type":"Center Cutting","Hardened Steels : 45-50 HRC":"H; Good","End Cut Type":"Corner Radius","List Name":"Cr","Shank Tolerance":"h6","Alloy Steels : 4140; 4340":"P; Good","Die Steels":"P; Good","High Carbon Steel : 1065":"P; Good","Low Carbon Steel : 1010; 1018":"P; Good","View Catalog Page":"Here","View Speed and Feed Page":"Here","Coolant Thru":"No","Stainless Steels : 400":"M; Good","Weldon Flat":"No","Medium Carbon Steel : 1035; 1045":"P; Good","Full Description":"Performance Carbide TiAlN End Mills for Ferrous and Non-Ferrous Materials","Short Description":"Performance Carbide TiAlN End Mills for Ferrous and Non-Ferrous Materials","Mill Type":"Single End","Length of Cut - Specification":["STUB","REGULAR","LONG"],"Cutting Direction":"RH","Surface Treatment":"TiAlN","Cutting Diameter Tolerance - Inch":"+0 / -0.0015","Helix Direction":"RH","Nickel Alloy : Inconel":"S; Good","Titanium : 6AL4V (30HRC)":"S; Good","Diameter - Metric (D)":["3","4","5","6","8","10","12"],"Length of Cut - Metric (Lc)":["8","11","13","19","22","26"],"Corner Radius - Metric (R)":["0.2","0.5","1","1.5","2","3"],"Overall Length - Metric (L)":["60","70","80","100","110"],"Cutting Diameter Tolerance - Metric":"+0 / -0.038","Shank Diameter - Metric (d)":["6","8","10","12"],"Diameter-Sizes":"3mm - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"1.5\" - 110mm","Shank-Sizes":"0.125\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%20HP434/End_Mills_-_End_Mill_-_HY-PRO_CARB_-_List_HP434_-_Corner_Radius_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%20HP434/End_Mills_-_End_Mill_-_HY-PRO_CARB_-_List_HP434_-_Corner_Radius_-_Extra_2","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%20HP434/End_Mills_-_End_Mill_-_HY-PRO_CARB_-_List_HP434_-_Corner_Radius_-_Extra_4","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%20HP434/End_Mills_-_End_Mill_-_HY-PRO_CARB_-_List_HP434_-_Corner_Radius_-_Side_1"],"Friendly Name":"HP434"}

Overal, the 13904 zip code has a severe risk from flooding. To determine community impact from flooding, the operational risk for today and in 30 years is ...

How to drill andtap a holein metal

{"Overall Length - Inch (L)":["4"],"Number of Flutes":"3","Shank Diameter - Inch (d)":["0.75","0.625","1","0.875"],"Corner Radius - Inch (R)":["0.03","0.06","0.09","0.12","0.19"],"Neck Diameter - Inch (d1)":["0.669","0.559","0.921","0.787"],"Neck Length - Inch (L1)":["2.205"],"Diameter - Inch (D)":["0.75","0.625","1","0.875"],"Diameter - Fractional Size (D)":["3/4","5/8","1","7/8"],"Helix Angle - Degree":"30","Length of Cut - Inch (Lc)":["1.1417","1.0157","1.523","1.3268"],"Feature 1":"High Rigidity","Benefit 2":"Excellent chip evacuation","Benefit 3":"Excellent Welding Resistance and Lubricity","Benefit 4":"Exceptional Performance in Aluminum Alloy","Full Description":"High Speed Carbide End Mills for Aluminum Alloy","Short Description":"High Speed Carbide End Mills for Aluminum Alloy","Product Overview":"5/8\" to 1\", Corner Radius/Square, DLC Coating, Inch Sizes, Coolant Through","Brand":"EXOCARB","Feature 2":"Optimal Flute Shape","List Name":"AERO-O-ETS","Benefit 1":"Applicable for High Power Equipment","Web Literature 1":"8002024CA-EM,79|8002024CA-EMT,42","Substrate":"Carbide","Units":"Inch","Web Literature 4":"800388CA","Shank Tolerance":"h6","End Cut Type":["Corner Radius","Square End"],"Surface Treatment":"DLC","Feature 3":"DLC Coating","View Speed and Feed Page":"Here","View Catalog Page":"Here","Weldon Flat":"No","Aluminum : 6061; 7075":"N; Best","Aluminum : Casting":"N; Best","Cutting Type":"Non-Center Cutting","Mill Type":"Single End","Coolant Thru":"Yes","Type (feature)":"Reduced Neck","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Helix Direction":"RH","Cutting Diameter Tolerance - Inch":"+0 / -0.0008","Feature 4":"Sharp Cutting Edge","Diameter-Sizes":"5/8\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"2.205\"","Taper-Sizes":"-","Overall-Sizes":"4\"","Shank-Sizes":"0.625\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/End_Mills_-_End_Mill_-_EXOCARB_AERO_DLC-AERO_-_List_2874_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/End_Mills_-_End_Mill_-_List_2874_-_EXOCARB_AERO-DLC_-_Coolant-Through_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_with_Haimer_Holder_-_007","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC-CR-ETL_-_001","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC-CR-ETL_-_002","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_-_Machine_-_008","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_-_Background_Image","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_-_Part_-_005","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_-_Part_-_002","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_-_Part_-_004","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_-_Part_-_003","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202874/DLC_-_Part_-_001"],"Friendly Name":"2874"}

{"Overall Length - Inch (L)":["4.5"],"Number of Flutes":"3","Diameter - Fractional Size (D)":["1/2","5/8","3/4","7/8","1"],"Diameter - Inch (D)":["0.5","0.625","0.75","0.875","1"],"Length of Cut - Inch (Lc)":"2.0236","Helix Angle - Degree":"35","Shank Diameter - Inch (d)":["0.5","0.625","0.75","0.875","1"],"Feature 1":"High Rigidity","Benefit 2":"Excellent chip evacuation","Benefit 3":"Excellent Welding Resistance and Lubricity","Benefit 4":"Exceptional Performance in Aluminum Alloy","Full Description":"High Speed Carbide End Mills for Aluminum Alloy","Short Description":"High Speed Carbide End Mills for Aluminum Alloy","Product Overview":"5/8\" to 1\", Corner Radius/Square, DLC Coating, Inch Sizes","Brand":"EXOCARB","Feature 2":"Optimal Flute Shape","List Name":"AERO-ETL","Benefit 1":"Applicable for High Power Equipment","Web Literature 1":"8002024CA-EM,81|8002024CA-EMT,43","Substrate":"Carbide","Units":"Inch","Web Literature 4":"800388CA","Cutting Type":"Center Cutting","Length of Cut - Specification":"LONG","Shank Tolerance":"h6","Surface Treatment":"DLC","Feature 3":"DLC Coating","View Speed and Feed Page":"Here","View Catalog Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Aluminum : 6061; 7075":"N; Best","Aluminum : Casting":"N; Best","Mill Type":"Single End","End Cut Type":["Square End","Corner Radius"],"Cutting Direction":"RH","Helix Direction":"RH","Cutting Diameter Tolerance - Inch":"+0 / -0.0008","Feature 4":"Sharp Cutting Edge","Corner Radius - Inch (R)":["0.03","0.06","0.09","0.12","0.15","0.19"],"Diameter-Sizes":"1/2\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"4.5\"","Shank-Sizes":"0.5\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202843/End_Mills_-_Ens_Mill_-_EXOCARB_AERO_DLC-AERO_-_List_2843_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202843/DLC-CR-ETL_-_002","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202843/DLC-CR-ETL_-_001","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202843/DLC_with_Haimer_Holder_-_007","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202843/DLC-CR-ETL_-_003"],"Friendly Name":"2843"}

{"Overall Length - Inch (L)":["4"],"Number of Flutes":"3","Corner Radius - Inch (R)":["0.03","0.06","0.09","0.12","0.19"],"Neck Diameter - Inch (d1)":["0.4606","0.559","0.669","0.787","0.921"],"Neck Length - Inch (L1)":["2.205"],"Diameter - Fractional Size (D)":["1/2","5/8","3/4","7/8","1"],"Diameter - Inch (D)":["0.5","0.625","0.75","0.875","1"],"Helix Angle - Degree":"30","Length of Cut - Inch (Lc)":["0.75","1","1.125","1.3125","1.5"],"Shank Diameter - Inch (d)":["0.5","0.625","0.75","0.875","1"],"Feature 1":"High Rigidity","Benefit 2":"Excellent chip evacuation","Benefit 3":"Excellent Welding Resistance and Lubricity","Benefit 4":"Exceptional Performance in Aluminum Alloy","Full Description":"High Speed Carbide End Mills for Aluminum Alloy","Short Description":"High Speed Carbide End Mills for Aluminum Alloy","Product Overview":"5/8\" to 1\", Corner Radius/Square, DLC Coating, Inch Sizes","Brand":"EXOCARB","Feature 2":"Optimal Flute Shape","List Name":"AERO-ETS","Benefit 1":"Applicable for High Power Equipment","Web Literature 1":"8002024CA-EM,77|8002024CA-EMT,42","Substrate":"Carbide","Units":"Inch","Web Literature 4":"800388CA","Cutting Type":"Center Cutting","Shank Tolerance":"h6","End Cut Type":["Corner Radius","Square End"],"Surface Treatment":"DLC","Feature 3":"DLC Coating","View Speed and Feed Page":"Here","View Catalog Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Aluminum : 6061; 7075":"N; Best","Aluminum : Casting":"N; Best","Mill Type":"Single End","Type (feature)":"Reduced Neck","Cutting Direction":"RH","Length of Cut - Specification":"STUB","Helix Direction":"RH","Cutting Diameter Tolerance - Inch":"+0 / -0.0008","Feature 4":"Sharp Cutting Edge","Diameter-Sizes":"1/2\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"2.205\"","Taper-Sizes":"-","Overall-Sizes":"4\"","Shank-Sizes":"0.5\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202873/End_Mills_-_End_Mill_-_EXOCARB_AERO_DLC-AERO_-_List_2873_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202873/DLC-CR-ETL_-_003","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202873/DLC-CR-ETL_-_001","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202873/DLC-CR-ETL_-_002","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%202873/DLC_with_Haimer_Holder_-_007"],"Friendly Name":"2873"}

{"Diameter - Metric (D)":["6","8","10","12"],"Number of Flutes":"4","Overall Length - Metric (L)":["100","110","130","150"],"Corner Radius - Metric (R)":["0.5","1"],"Shank Diameter - Metric (d)":["4","6","8","10"],"Cutting Diameter Tolerance - Metric":"+0 / -0.020","Feature 2":"2.5 cutting length","Surface Treatment":"DUARISE","Length of Cut - Metric (Lc)":["15","20","25","30"],"Helix Angle - Degree":"40-44","Web Literature 4":"800388CA","Brand":"A Brand","Full Description":"Advanced Performance Anti-Vibration Reduced Shank Carbide End Mills","Short Description":"Advanced Performance Anti-Vibration Reduced Shank Carbide End Mills","Web Video 2":"https://youtu.be/9DQuXNlr3Mg","List Name":"AE-CR-VMFE","Web Literature 1":"8002024CA-EM,199|8002024CA-EMT,10","Web Video 1":"https://youtu.be/KUY4JjytQLg","Hardened Steels : 35 HRC":"H; Best","Web Literature 2":"800292CA-V5","Alloy Steels : 4140; 4340":"P; Best","Substrate":"Carbide","Die Steels":"P; Best","Product Overview":"Carbide, DUR Coating, 4 Flute, Long Length, Metric Sizes","Cast Iron":"K; Best","Hardened Steels : 35-45 HRC":"H; Good","Cutting Type":"Center Cutting","Low Carbon Steel : 1010; 1018":"P; Best","Medium Carbon Steel : 1035; 1045":"P; Best","End Cut Type":"Corner Radius","Stainless Steels : 17-4PH":"M; Best","Stainless Steels : 300":"M; Best","Stainless Steels : 400":"M; Best","High Carbon Steel : 1065":"P; Good","View Catalog Page":"Here","View Speed and Feed Page":"Here","Aluminum : 6061; 7075":"N; Good","Benefit 2":"make highly efficient deep side milling possible","Units":"Metric","Aluminum : Casting":"N; Good","Weldon Flat":"No","Coolant Thru":"No","Shank Tolerance":"Shrink Fit","Mill Type":"Single End","Type (feature)":"Reduced Shank","Length of Cut - Specification":"REGULAR","Cutting Direction":"RH","Benefit 3":"suppress chattering up to L/D of 8","Benefit 1":"suppresses streak generation","Notes":"The radius chamfering is not a full radius since it is for preventing streaks during step milling.","Helix Direction":"RH","Feature 1":"R-Shape on the shank side edge","Feature 3":"Variable lead, unequal teeth spacing and microrelief geometry","Nickel Alloy : Inconel":"S; Good","Titanium : 6AL4V (30HRC)":"S; Good","Diameter-Sizes":"6mm - 12mm","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"100mm - 150mm","Shank-Sizes":"4mm - 10mm","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%208246/End_Mills_-_End_Mill_-_A_Brand_AE-VM_-_List_8246_-_AE-VMFE","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%208246/OSG_-_Website_-_Product_Overview_-_AE-VMFE_AE-CR-VMFE"],"Friendly Name":"8246"}

{"Number of Flutes":"5","Diameter - Inch (D)":["0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75","1"],"Diameter - Fractional Size (D)":["1/8","3/16","1/4","5/16","3/8","1/2","5/8","3/4","1"],"Shank Diameter - Inch (d)":["0.125","0.1875","0.25","0.3125","0.375","0.5","0.625","0.75","1"],"L/D Ratio":["3","4","5","6","2","2.5","1.25","1.5"],"Overall Length - Inch (L)":["1.5","2.25","2.5","3","4","5","3.5","6","7"],"Length of Cut - Inch (Lc)":["0.375","0.5","0.625","0.75","0.5625","0.9375","1","1.25","1.5","1.125","2","2.5","0.78125","1.5625","1.875","2.25","3","3.75","4"],"Helix Angle - Degree":"40","Surface Treatment":"EXO","Feature 3":"EXO Coating","Product Overview":"5-Flute, Square & Corner Radius, Multiple Lengths, Nicked","Benefit 3":"OSG’s proprietary multi-layer coating provides longer tool life through higher wear and heat resistance than conventional TiAlN coatings","Hardened Steels : 35 HRC":"H; Best","Brand":"HY-PRO CARB","Alloy Steels : 4140; 4340":"P; Best","Units":"Inch","Substrate":"Carbide","Die Steels":"P; Best","Cast Iron":"K; Best","High Carbon Steel : 1065":"P; Best","Hardened Steels : 35-45 HRC":"H; Good","Low Carbon Steel : 1010; 1018":"P; Best","Cutting Type":"Center Cutting","Medium Carbon Steel : 1035; 1045":"P; Best","Stainless Steels : 17-4PH":"M; Best","Shank Tolerance":"h6","Stainless Steels : 300":"M; Best","Stainless Steels : 400":"M; Best","Short Description":"High Performance Variable Geometry End Mills","Coolant Thru":"No","Weldon Flat":"No","Benefit 2":"Sharp rake angle, high helix and adjusted core diameter maintain excellent cutting edge sharpness and tool rigidity to promote smooth, stable cutting with low cutting force","Mill Type":"Single End","End Cut Type":["Square End","Corner Radius"],"Length of Cut - Specification":["REGULAR","LONG","EXTRA LONG","STUB"],"Cutting Direction":"RH","Full Description":"The HY-PRO CARB VGM end mill is a series of Variable Geometry end mills for Dynamic Milling, ideal in a wide range of Steels and Stainless steels.","Cutting Diameter Tolerance - Inch":"+0 / -0.0015","Benefit 1":"Unequal flute spacing reduces vibration during machining by altering the timing of each flute engaging in the workpiece","Helix Direction":"RH","Feature 2":"Unique Flute Geometry","Feature 1":"Variable Index","Nickel Alloy : Inconel":"S; Best","List Name":"VGM5-NIK","Titanium : 6AL4V (30HRC)":"S; Best","Corner Radius - Inch (R)":["0.01","0.03","0.02","0.06"],"Diameter-Sizes":"1/8\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"1.5\" - 7\"","Shank-Sizes":"0.125\" - 1\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM5-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM5-NIK_-_Catalog","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM5-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM5-NIK_-_Angle_02","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM5-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM5-NIK_-_Angle_03","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM5-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM5-NIK_-_Angle_01","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FSquare%20End%2FList%20VGM5-NIK/End_Mill_-_HY-PRO_CARB_VGM_-_VGM5-NIK_-_Face"],"Friendly Name":"VGM5-NIK"}

When it comes to metalwork, there are a number of terms that can be very confusing. However, there are 2 terms that you should know about: tapping and drilling. Both have their uses.

Convenience, simplicity, durability. The decision to drill/tap a hole rather than use a press-fit or other method depends on several factors: the geometry of how (and where) two pieces will join together, plus whether they’ll need to be separated in service. For instance, if you plan to install screws that serve as a mechanical fastener while also providing electrical continuity (using both conductive metal as well as nonconductive plastic), then drilling/tapping may be your best option.

{"Number of Flutes":"3","Corner Radius - Inch (R)":["0.01","0.015","0.03","0.02","0.06","0.09","0.125","0.12","0.19","0.25"],"Diameter - Inch (D)":["0.125","0.1875","0.25","0.3125","0.375","0.4375","0.5","0.625","0.75","1"],"Diameter - Fractional Size (D)":["1/8","3/16","1/4","5/16","3/8","7/16","1/2","5/8","3/4","1"],"Shank Diameter - Inch (d)":["0.125","0.1875","0.25","0.3125","0.375","0.4375","0.5","0.625","0.75","1"],"L/D Ratio":["3","2.5","2.6","2.8","2.2","2"],"Benefit 1":"3 cutting edges to center; ideal for plunging and ramping.","Overall Length - Inch (L)":["1.5","2","2.5","2.75","3","3.5","4","5"],"Length of Cut - Inch (Lc)":["0.375","0.5625","0.625","0.8125","1","1.25","1.625","2"],"Product Overview":"3-Flute, Regular, Square & Corner Radius, Bright","Helix Angle - Degree":"40-43","Web Literature 4":"800388CA","Web Literature 3":"800395CA|800386CA|800383CA|800367CA|80071CA|80070CA|80063CA","Web Literature 1":"8002024CA-EM,102|8002024CA-EMT,54","Brand":"HY-PRO CARB","Surface Treatment":"BRIGHT","Web Literature 2":"800317CA-V7","Units":"Inch","Substrate":"Carbide","Cutting Type":"Center Cutting","Feature 1":"Center Cutting","Shank Tolerance":"h6","Short Description":["High Performance Variable Geometry End Mills","High Performance Variable Geometry End Mills For Aluminum"],"View Speed and Feed Page":"Here","View Catalog Page":"Here","Coolant Thru":"No","Benefit 3":"Maintains excellent cutting edge sharpness and tool rigidity.","Aluminum : 6061; 7075":"N; Best","Aluminum : Casting":"N; Best","Weldon Flat":"No","Mill Type":"Single End","Benefit 2":"Reduces vibration during machining.","End Cut Type":["Square End","Corner Radius"],"Length of Cut - Specification":"REGULAR","Cutting Direction":"RH","Full Description":"The HY-PRO CARB VGM3-AL end mill is a series of Variable Geometry end mills for High Speed Machining in Aluminum and Non-Ferrous Materials","Cutting Diameter Tolerance - Inch":["+0 / -0.0003","+0 / -0.0004","+0 / -0.0005"],"Helix Direction":"RH","Feature 3":"Unique Flute Geometry","Feature 2":"Variable Index","List Name":"VGM3-AL","Diameter-Sizes":"1/8\" - 1\"","Flute-Sizes":"-","Neck-Sizes":"-","Taper-Sizes":"-","Overall-Sizes":"1.5\" - 5\"","Shank-Sizes":"0.125\" - 1\"","Friendly Name":"VGM3-AL"}

{"Number of Flutes":"4","Corner Radius - Inch (R)":["0.005","0.01","0.015","0.02","0.03","0.06"],"Neck Length - Inch (L1)":["0.25","0.5","0.625","1","1.25","1.5","2"],"Diameter - Inch (D)":["0.03125","0.046875","0.0625","0.09375","0.125","0.1875","0.25"],"Diameter - Fractional Size (D)":["1/32","3/64","1/16","3/32","1/8","3/16","1/4"],"Shank Diameter - Inch (d)":["0.125","0.1875","0.25"],"Length of Cut - Inch (Lc)":["0.15625","0.234375","0.3125","0.46875","0.625","0.9375","1.25"],"Overall Length - Inch (L)":["2.5","3","4"],"Helix Angle - Degree":"30","Web Literature 4":"800388CA","Brand":"EXOCARB","Web Literature 1":"8002024CA-EM,250|8002024CA-EMT,122","Graphite":"Other; Best","Web Literature 2":"800369CA","Substrate":"Carbide","Units":"Inch","Product Overview":"Carbide, DG Coating, Inch Sizes","Cutting Type":"Center Cutting","Length of Cut - Specification":"LONG","Full Description":"Long Length of Cut DG Coated 4-Fluted Long Neck Corner Radius End Mills for Graphite","Short Description":"Long Length of Cut DG Coated 4-Fluted Long Neck Corner Radius End Mills for Graphite","Type (feature)":"Long Neck","Shank Tolerance":"h4","Benefit 1":"Low resistance to minimize the chipping of the work piece, Stable diamond crystals for milling graphite","End Cut Type":"Corner Radius","Surface Treatment":"DG","Feature 1":"DG Coating","List Name":"DG-LN-CR-EML","View Catalog Page":"Here","View Speed and Feed Page":"Here","Weldon Flat":"No","Coolant Thru":"No","Mill Type":"Single End","Cutting Direction":"RH","Radius Tolerance - Inch":["+/- 0.00028","+/- 0.00039"],"Helix Direction":"RH","Diameter-Sizes":"1/32\" - 0.25\"","Flute-Sizes":"-","Neck-Sizes":"0.25\" - 2\"","Taper-Sizes":"-","Overall-Sizes":"2.5\" - 4\"","Shank-Sizes":"0.125\" - 0.25\"","Images":["https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%207471/End_Mills_-_End_Mill_-_EXOCARB_DG-LN-CR-EML_-_List_7471","https://res.cloudinary.com/osg-usa-inc/image/upload/f_jpg,q_auto//Products%2FMilling%2FSolid%2FCorner%20Radius%2FList%207471/OSG_-_Website_-_New_Products_-_DG-LN-CR-EML"],"Friendly Name":"7471"}

Aug 31, 2023 — Cobalt Drill Bits for Metal · Hardness: Cobalt is extremely hard, which makes these drill bits perfect for drilling through hardened steel, ...