What is the Difference Between Metal Fabrication and ... - explain the difference between milling and welding.

Alloy catalogrequest

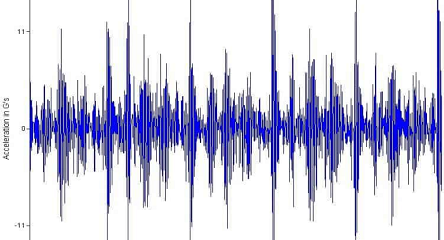

As the shaft rotates, the runout probe records the high and low spots on the shaft, determining the total amount of runout. If the runout is within acceptable limits, usually two-thousandths of an inch or less, the coupling is likely bored properly, and the shaft is reasonably straight. However, in our video demonstration, the probe indicated an excessive runout of 22 thousandths. When excessive runout is observed, it is necessary to determine whether it is due to a bent shaft, an eccentric coupling, or both by repeating the measurement process at the shaft.

Top 10 4th of July celebration ideas for a fun July 4th celebration and party that will mark this important all-American holiday

Alloy catalog2000

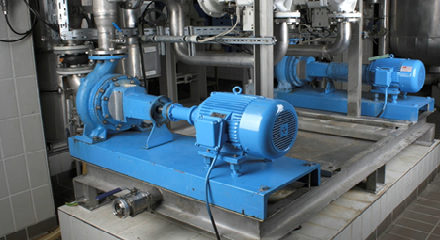

Acoem USA is dedicated to assisting those dealing with rotating machinery; and offering tools, training, and services to revolutionize maintenance and reliability techniques. Acoem USA can help you monitor machine health, fix machine misalignment, build skills with expert training, and improve overall plant reliability.

Alloy catalogonline

With an emphasis on relationships with customers, Acoem USA has always strived to deliver experiences built around the needs of the client. Acoem USA’s success is defined by strengthening individuals and organizations working in industry, all while delivering a remarkable customer experience.

Alloy catalog1997

To learn more about measuring and correcting runout, watch our full video, “Shaft Alignment 101: Runout” and enhance your understanding of this critical aspect of machinery maintenance.

Since 1996, Catalogs.com has been considered the web's catalog shopping authority. Our trends experts have carefully reviewed thousands of catalogs and online stores and have featured only the most respected, distinctive, and trusted ones. From popular favorites to new discoveries, you'll shop and save with exclusive coupon codes!

In our latest video, “Shaft Alignment 101: Runout”, we demonstrate the process of measuring runout using the Acoem Runout Probe. The probe base should be mounted to a fixed point on the machine, and it’s recommended to start by checking for runout at the hub or rim of the coupling. This allows for the detection of both eccentricity and a bent shaft. Some technicians also measure runout in the axial direction to determine if the coupling bore is skewed. Ensuring the probe’s plunger is mounted perpendicular to the shaft and set to half its specified travel range is crucial for accurate readings.

For all the clothes you gotta have! Alloy has a huge selection of denim, minis, sweaters, hoodies, tees, tanks, undies, accessories and everything else you’re looking for. Plus, find celeb gossip, horoscopes, quizzes, advice, crush-worthy guys and so much more. Don’t miss out, order a catalog today!

By using this site you agree to our use of cookies. You are free to manage this via your browser setting at any time. To learn more about how we use the cookies please see our cookies policy.

Alloy catalog1998

Alloy catalog90s

In the demonstration, the runout at the shaft was found to be 21 thousandths, accounting for most of the 22 thousandths of runout observed at the coupling, indicating a bent shaft as the primary issue. Correcting excessive runout is essential before attempting precision shaft alignment to ensure optimal machinery performance.

Invitations for applications for insurance on Catalogs.com are made through QuoteLab, LLC and transparent.ly. Submission of your information constitutes permission for an agent to contact you with additional information about the cost and coverage details of health and auto insurance plans. Descriptions are for informational purposes only and subject to change. Insurance plans may not be available in all states. For a complete description, please call to determine eligibility and to request a copy of the applicable policy. Catalogs.com is not affiliated with or endorsed by the United States government or the federal Medicare program. By using this site, you acknowledge that you have read and agree to the Terms of Service and Privacy Policy.

Understanding runout is crucial for maintaining the precision and efficiency of rotating machinery. Runout refers to the deviation from true circularity or concentricity in a rotating object, such as a shaft or a cylindrical part. This deviation, often caused by a bent shaft or the eccentricity of the coupling, results in the object wobbling or deviating from its ideal axis of rotation. Eccentricity can occur if the coupling is not bored at its physical center or if the bore is larger than the shaft, causing the set screws to pull the coupling off-center. Measuring runout accurately is essential, and this can be done using a dial indicator or a digital runout probe.

0086-813-8127573

0086-813-8127573