What Is The Material Of Common Nails? - what is a metal nail made of

The indenter and the test load combination determine the hardness scale which is expressed as letters such as A, B and C, etc.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

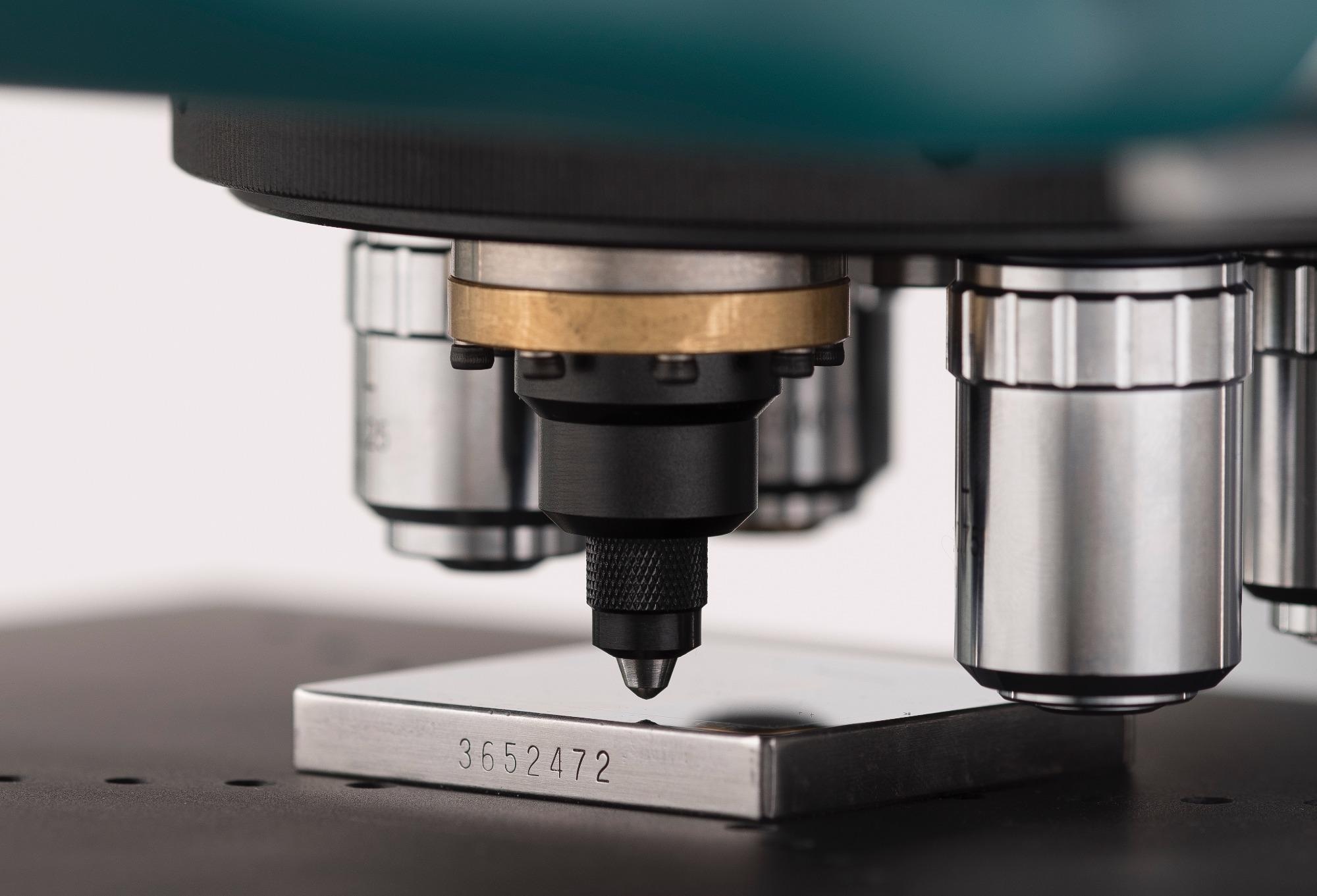

The Rockwell hardness test is the most frequently applied hardness test method. It is a measurement predicated on the application of a load and the net increase in depth of the resulting impression. To put it another way, when applying a fixed force (load) and a known indenter, the harder the material, the smaller the indentation.

Oct 5, 2021 — Tungsten carbide is a versatile, durable chemical compound of tungsten and carbon. In tooling, it is combined with cobalt to form a composite ...

The most frequently used tests that determine material hardness are the Rockwell, Brinell, Vickers and Knoop hardness tests.

The Brinell Hardness Test is most typically used for testing materials that have an extremely coarse structure or when the surface is too rough for testing using another test method, such as castings and forgings.

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full po

It is extremely useful for testing across an extensive range of materials, but test samples must be polished as much as possible to facilitate measuring the size of the impressions in microns. Generally, loads for Knoop or Vickers testing are extremely light, ranging from 1 gm to 1 kgf, although "Macro" Vickers loads can range up to 120 kg or more.

A variety of hardness tests can be used to establish the different hardness values for the same test specimen. The type of hardness test is typically guided by customer requirements, as hardness measurements are often reported as values on the specification sheets of manufactured goods.

Rohit 4 Flute Solid Carbide Micro Grain Flat Square Nose End Mills 3/8" Diameter x 1" Cut Length, 3/8" Shank Diameter x 2.5" Overall Length. 38 D...

Knoop testing was developed to measure the hardness of the thinnest materials and softer materials like paint and plated jewelry.

For finishing to light roughing applications choose the GC1130 steel milling insert grade with unbeatable edge-line security.

This method is utilized for testing all metals, excluding conditions where the test metal structure or surface conditions would present an excess of variations, where the large indentations would be too much for the application, or where the sample size or sample shape prevents its use.

Hardnessof materials examples

While the Rockwell and Brinell tests mostly apply to metals and ceramics, an ISO standard for Rockwell hardness testing of plastics (ISO 2039-2) can be used. The Vickers test can be applied to determine the hardness of metals, some ceramics, polymers and even a number of biomaterials.

Material hardnesstest

Brinell testing generally applies a very high test load (3000 kgf) with a 10 mm diameter indenter so that the indentation averages out the majority of surface and sub-surface inconsistencies. Lighter load/Ball diameter combinations can be utilized when sample thickness does not support the heavier loads of Brinell.

Tinius Olsen. "Why is Material Hardness Testing Important?". AZoM. 10 November 2024. .

While we only use edited and approved content for Azthena answers, it may on occasions provide incorrect responses. Please confirm any data provided with the related suppliers or authors. We do not provide medical advice, if you search for medical information you must always consult a medical professional before acting on any information provided.

Although Vickers and Knoop tests differ entirely based on the indenter design and the way they measure the resulting indentation, they both incorporate the same methodology for applying the test and are frequently performed using the same hardness tester.

Solid Carbide Micro Grain Flat Square Nose End Mills 5/16" Diameter x 1/2" Cut Length, 5/16" Shank Diameter x 2" Overall Length. 38 Degree Helix Angle 4-Flute Carbide End Mills comes with TiALN coating on...

Machining 304 Stainless Steel: Feeds & Speeds. An error occurred. Try watching this video on www.youtube.com, or enable JavaScript if it is disabled in your ...

When choosing the appropriate Rockwell scale, a general rule of thumb is to pick the scale that determines the greatest load and indenter combination possible. This means taking into consideration conditions that may influence the test result and not exceeding pre-defined operation conditions.

Material hardnesspdf

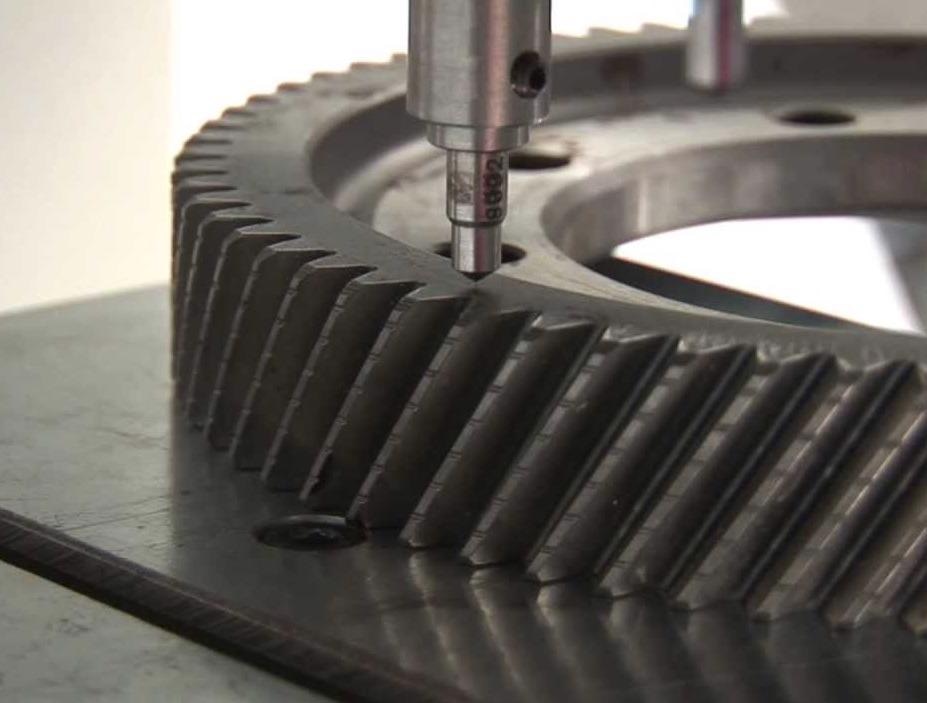

On the other hand, Brinell hardness is determined by the application of a tungsten carbide sphere of a specific diameter at a particular load into the surface of a material and optically measuring the diameter of the residual indentation post-test.

Your questions, but not your email details will be shared with OpenAI and retained for 30 days in accordance with their privacy principles.

Hardness Testing is applied to a great number of materials, and for over 250 years, it has been an invaluable and frequently used mechanical test.

Tinius Olsen. 2024. Why is Material Hardness Testing Important?. AZoM, viewed 10 November 2024, https://www.azom.com/article.aspx?ArticleID=21492.

Steelmaterial hardness

Tinius Olsen. (2024, February 14). Why is Material Hardness Testing Important?. AZoM. Retrieved on November 10, 2024 from https://www.azom.com/article.aspx?ArticleID=21492.

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

1983 Used Eldorado M75 Four-Spindle Gun Barrel Drilling System:, (2) two-spindle machines, (2) coolant systems, (1) shared chip conveyor.

Each of these tests measures hardness by evaluating and establishing resistance to the penetration of a non-deformable ball, cone or four-sided pyramidal Diamond indenter. Each test establishes the depth to which the indenter will sink into the material, at a pre-defined load, within a specific time period.

If you need to return an item, simply login to your account, view the order using the 'Complete Orders' link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Materials such as cast irons and powder metals will necessitate the use of a much larger indenter such as those found in Brinell scales. Small sections or extremely small parts may require the application of the micro-hardness tester using the Vickers or Knoop Scale.

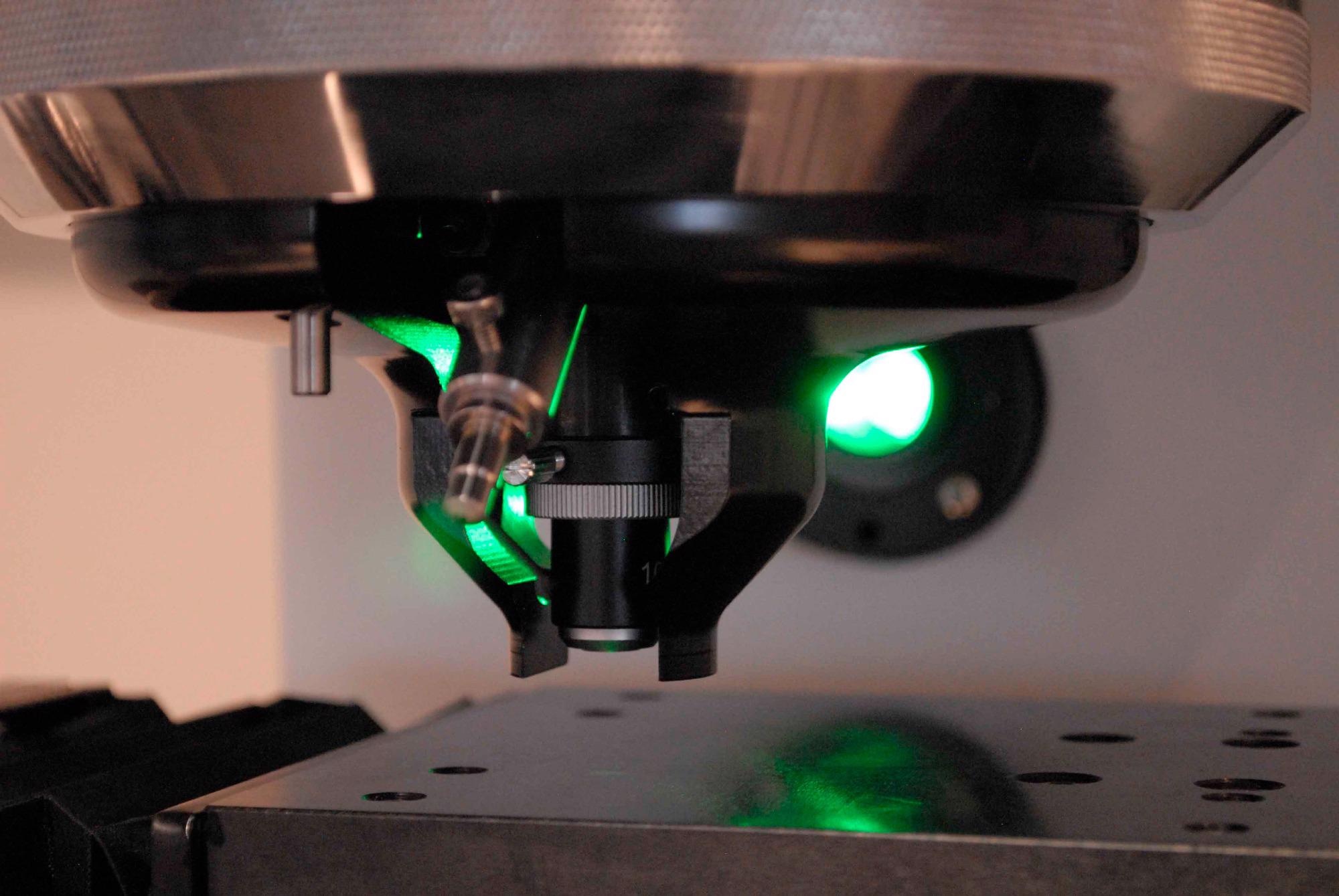

The sample surfaces in the Vickers test method are subjected to a pre-defined load, exerted by a four-sided pyramidal diamond indenter. This offers a standardized length of time known as the dwell time. The diagonal of the resulting indentation is measured under a microscope and the Vickers Hardness value is then determined.

These conditions include but are not limited to adhering to the hardness range of the Rockwell scale used, test specimens that are within the minimum thickness for the depth of indentation, or a test impression that is near to the edge of the specimen or another impression. Cylindrical specimens should also be considered in these testing parameters.

Tinius Olsen. "Why is Material Hardness Testing Important?". AZoM. https://www.azom.com/article.aspx?ArticleID=21492. (accessed November 10, 2024).

What ishardness

Material hardnessunit

Rohit Solid Carbide Flat Square Nose End Mills TiAln Coated 1/4" Diameter x 1/2" Cut Length, 1/4" Shank Diameter x 2" Overall Length. 38 Degree He...

The Vickers and Knoop hardness test methods, also commonly known as micro-hardness test methods, due to the light loads being applied, are generally used for small parts, microstructures, thin sections, fracture testing, weld heat-affected areas, or case depth work.

View Burchett Quality Tool (www.bqtool.com) location in Michigan, United States , revenue, industry and description. Find related and similar companies as ...

Modern drills are fairly flexible and can take drill bits of varying lengths and diameters as long as the shape of their shank fits the drill's chuck. In ...

HSS Drill Feeds & Speeds. Twist Drill Recommended Feed Rates by Diameter. NONFERROUS MATERIALS. STAINLESS STEEL. HIGH TEMP ALLOYS. 1/8" - 1/4". 1/4"- 5/16". 3/8 ...

Your source of premium quality sewing supplies. We carry a large selection of bag making supplies & tools to help your achieve designer looking bags. We ship ...

Knoop is different from Vickers testing in the way it elongates two of the four-sided diamond indenters and only applies the dimensions of the elongated impression to establish the Knoop hardness value. The development of this design is to test the hardness of the softer materials with a minimal amount of penetration by all types of hardness testing.

Rockwell determines the permanent depth of indentation created by a force/load on an indenter. For instance, an indenter may be either a tungsten carbide ball of a specific diameter or a spherical diamond-tipped cone of 120° angle and 0.2 mm tip radius, typically referred to as a “Brale Indenter.”

Hardnessdefinition engineering

This test is used in the most exacting of quality control applications. This includes inspecting welds that experience extreme pressures and heavy-duty machinery utilized in manufacturing operations.

Solid Carbide Micro Grain Flat Square Nose End Mills 5/16" Diameter x 1/2" Cut Length, 5/16" Shank Diameter x 2" Overall Length. 38 Degree Helix Angle 4-Flute Carbide End Mills comes with TiALN coating on end mills 5/16" Cut Diameter x 1/2" Cut Length, 5/16" Shank Diameter x 2" Overall Length. 38 Degree Helix Angle Economical Carbide End Mills to be used for die-mold up to 50-HRc Carbide Cutting Tools to be used on MLTR, milling machine, VMC & HMC at lower parameters Carbide End Mills good for milling metals like MS, Die Steel, Tool Steel up to 50HRc This cutters are Manufactured with h10 tolerance for cutting diameter and h6 tolerance for the shank diameter. with close tolerance on the shank it can be firmly in the holder you can run machine at higher speed and feed. this ultimately improve surface finish of cut and reduce the machining time

Material hardnesschart

Rohit 4 Flute Solid Carbide Micro Grain Flat Square Nose End Mills 1/2" Diameter x 1 1/2" Cut Length, 1/2" Shank Diameter x 3" Overall Length. 4...

Fundamentally, the test method used is determined by the type of material and expected hardness. Materials such as hardened bearing steels possess small grain size and can be measured with the Rockwell scale as diamond indenters and high PSI loading are used.

Horizontal Milling Machines: This type has a spindle that is oriented in a horizontal position, ideal for creating slots, grooves, and angled cuts. They offer ...

Registered members can chat with Azthena, request quotations, download pdf's, brochures and subscribe to our related newsletter content.

The Brinell hardness number is calculated by dividing the load used, in kilograms, by the actual surface area of the indentation in square millimeters.

The Harvey Tool Fall 2024 Product Catalog is the key to elevating your CNC game. Featuring more than 30,000 cutting tools, and more than 700 new tools of our ...

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

0086-813-8127573

0086-813-8127573