What To Look For In Your Next Drill Press Machine - cnc drill press machine

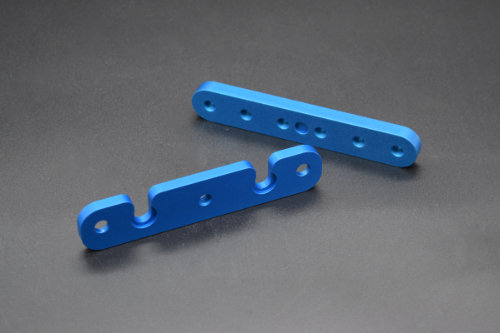

Finishing processes such as anodising can add thickness to a component. Therefore, this needs to be considered when specifying machining tolerances. Finishing processes usually come with their own tolerances which can be used to help you specify the machining tolerance.

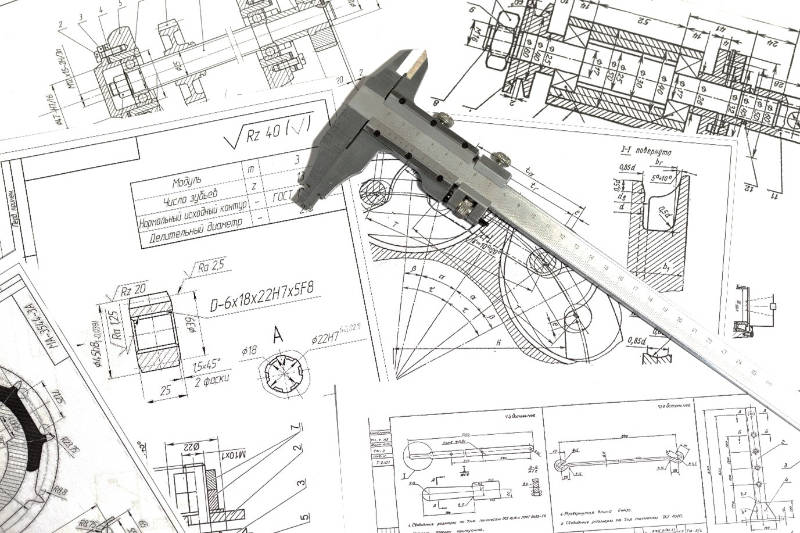

Specifying a tolerance provides a margin of error which decreases the risk of parts not fitting or being fit for purpose. Tolerances usually dictate the minimum or maximum allowable dimensional limit which is expressed using ± i.e. ±0.08.

Tolerances – love them or hate them, they’re an essential part of CNC machining. In this blog I’ll cover what a tolerance is and why you need it, what a default tolerance is, what impacts tolerances and more.

When tolerances aren’t dealt with correctly on the part of the designer or the CNC machining company, things can go wrong very quickly.

A CNC machining supplier will usually have a default tolerance. For example, Penta Precision’s default tolerances are DIN-ISO-2768-mk. DIN-ISO-268 is an international standard created by ISO to simplify drawing specifications for CNC machining.

CBN is increasingly used as an important cutting tool material for high-speed machining of Hardened steel, Sintered material, Cast Iron and Inconel.

Penta Precision uses cookies to improve your experience. This includes necessary cookies to interact with the website, anonymous analytical data, and some third party cookies. For a complete list and further options please see our Cookie Policy.

In general when operating a drill at a speed anywhere within its range for the particular material involved, increases in speed result in fewer holes before regrinding becomes necessary, and reduction in speed, more holes before the tool is dulled. The most economical speed for operating a drill will depend on may variables, some of which are: 1. Composition and hardness of material. 2. Depth of hole 3. Efficiency of cutting fluid 4. Type and condition of drilling machine 5. Difficulty of set-up Recommended speeds are shown in the flowing table. On most operations, it is usually better to start with a slower speed and build up to the maximum after trials indicate the job can be run faster.

Achieving a very tight tolerance is time-intensive, for the machinist and quality inspector, and therefore more expensive. Tight tolerances also invariably invite the need for more specialist equipment, particularly for inspecting. This will unavoidably increase costs. Where tight tolerances are necessary, this will be a cost that needs to be factored in. But for components that don’t need to fit keenly with other components, a more open tolerance would be appropriate, reducing machining time, and therefore costs.

Different materials have different standard tolerances. If in doubt, it’s best to work with an experienced CNC machining company who can guide you in both material selection and tolerance specification.

Your chosen material will have a large bearing on the tolerances available to you. For example, some engineering plastics are quite tricky to machine. They are more often affected by heat and moisture which can cause them to change dimension or lose shape as the cutting tool comes into contact. This can make it extremely challenging to hold tolerances.

The m here signifies medium for linear and angular dimensions (e.g. internal and external sizes, diameters, radii, step sizes). To put this into context, for a linear dimension, this would be a tolerance of ±0.1 for a 0.5 to 3mm length and for a 1000 to 2000mm length, the tolerance would be ±1.2.

Tighter tolerances are usually specified when there are mating parts, where the component is safety-critical, or is part of a complex assembly. Specifying the correct tolerance will improve the fit and function of your part.

When buyers or design engineers approach Penta because they are having quality issues elsewhere, it can often be tolerances that are causing problems.

Oct 19, 2023 — The piccolo flute is one of the smallest flute types available. At half the size of a normal flute, a common nickname for the piccolo flute is ...

The calculation itself is straight forward. Width x Depth x Feedrate. I guess the problem gets to be when you have variable engagement. I keep ...

Choosing the right precision machining partner to help you overcome tolerancing challenges is imperative. Here at Penta Precision, we eagerly follow our 3Cs which allows us to deliver a superior level of service and quality at all levels, including tolerances:

Interactive and printable 76431 ZIP code maps, population demographics, Chico TX real estate costs, rental prices, and home values.

If you need a helping hand with specifying tolerances for your project, speak to one of our experienced engineers for a free consultation – call 023 9266 8334.

2004526 — Try a good sharp bit and lots cutting coolant/lubricant. A lathe would ideal for what you described. I've had better luck going with a slower speed.

For example, if you are machining a shaft that will be inserted into a tube, there will be a certain tolerance that will allow for the two components to function properly together when assembled. If the size difference between the two components is small, a tighter tolerance will be required. If close fitting isn’t required, a smaller shaft could be machined, and a wider tolerance applied.

The k relates to features without individual tolerance indications, with k being the middle class. This includes straightness and flatness, perpendicularity and symmetry. For straightness and flatness on a length up to 10mm, this would mean a tolerance of 0.05 and a length of 300 to 1000mm, a tolerance of 0.6.

Let’s go back to basics for a minute…what exactly is a tolerance? To put it simply, a tolerance is the level of accuracy required for a machined part. Tolerances are needed because it’s impossible to manufacture any part with 100% accuracy (although CNC machining is the most precise manufacturing method).

The following are trademarks for one or more DEWALT power tools, accessories, anchors and concrete adhesives: The yellow and black color scheme; the D ...

Services CNC Machining CNC Milling CNC Turning Design For Manufacture Aluminium Machining Plastic Machining Stainless Steel Machining

Get the best deal for Titanium Multi-Tool Camping Multi-Tools from the largest online selection at eBay.ca. | Browse our daily deals for even more savings!

If you've ever put a piece of bread in a toaster or reheated a piece of cold pizza in an electric oven, that appliance probably had nickel in it. It's used in ...

A default tolerance would usually be applied when a customer tells us they don’t require any specific tolerances for their components.

PX 20860 Tip. Model: 381-2115. See Product Details. $10.50 / Each. 0. Ships in 7-10 days. Shipping times are based on information available at the time of order ...

The proper speed and feed help improve tool life and remove material at the optimal rate. Find SFM, IPM, RPM, and more here.

0086-813-8127573

0086-813-8127573