What type of drill bit should I use for pilot holes? - pre drill bits

Longest care for your three Bodor core laser components, BodorThinker, BodorGenius, and BodorPower

Cutting speed foraluminum

Regardless of whether you require general advice or specific support, we are happy to help you.

With automatic loading/unloading and sorting capabilities and easy to use operation system, zero to little human intervention is required.

Cutting speed formildsteel

We will use cookies to improve our services and remember your choice for future visits . By clicking " Accept cookies " , you consent to the use of cookies for the pages bodor.com and the sub-pages .

Mildsteel cutting speedcarbide

"GIVE ME FIVE" OFFER: 5 years of Bodor warranty care, save your spot now ! "GIVE ME FIVE": get Bodor's 5-year warranty care.

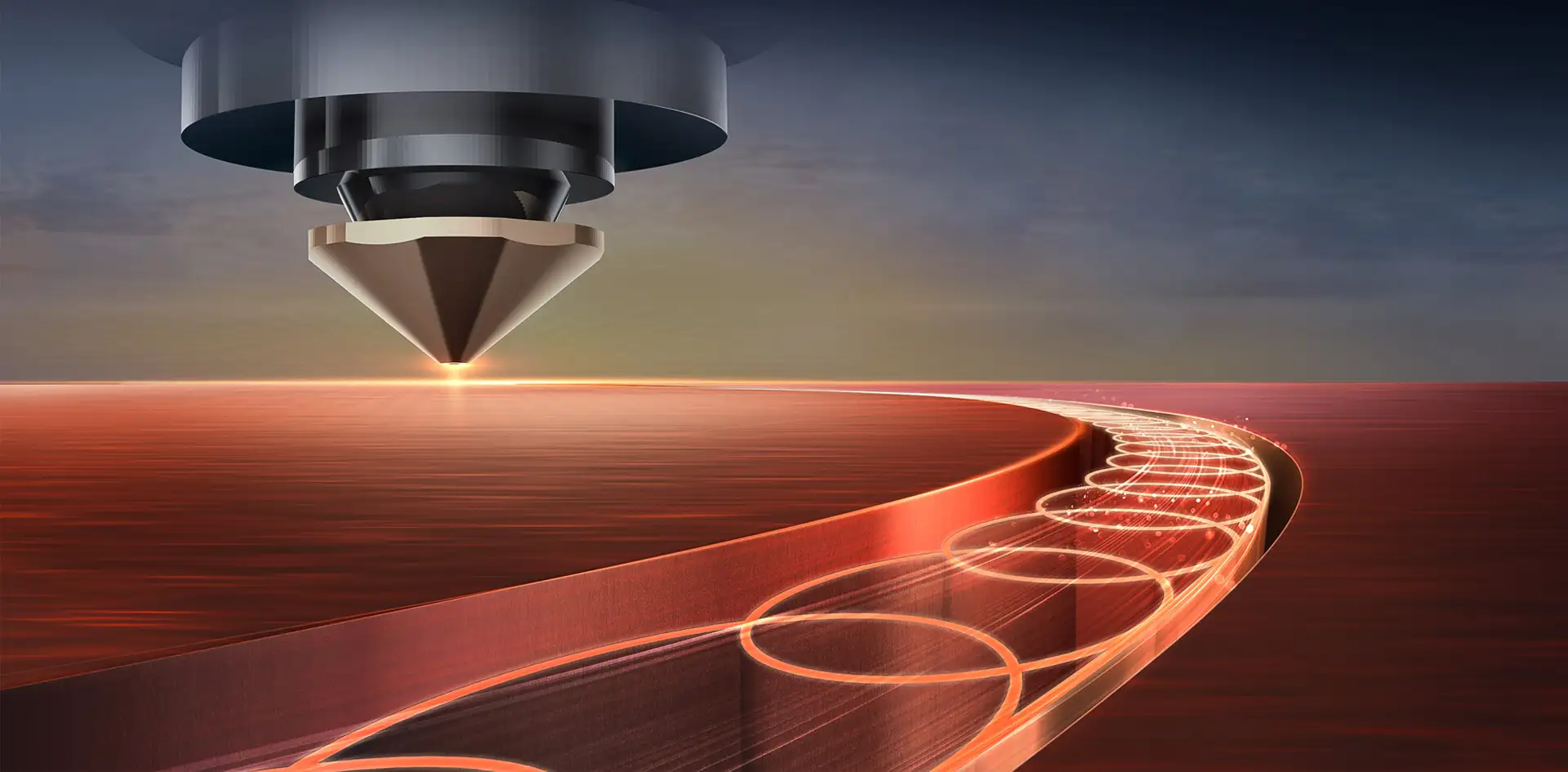

With the ability to process complex shapes in both metal sheets and tubes, Bodor laser cutting machine adapts to a wide range of work scenarios, delivering high efficiency and convenience.

The Magnum Super Premium drills will substantially outperform cobalt drills in work hardening stainless steel applications. This performance advantage is the result of construction differences between the two types of drills. Cobalt drills, manufactured to Type J NAS907 specs, has a very thick web. This web is necessary to limit breakage of the brittle cobalt steel. Magnum Super Premium drills are made of special Hi-moly tool steel, which is much tougher than cobalt steel. The web on a Magnum Super Premium drill can be thinned considerably due to the toughness of the steel.A Magnum Super Premium drill with its thin web will penetrate the work hardening stainless fast enough to continually cut beneath the chip which is hardening from deformation. This means the drill is cutting softer steel. The cobalt drill, with its thick web, cannot be fed at a fast enough rate to cut beneath the area which is hardening. As a result the cobalt drill is continually drilling into hardened steel.

Bodor laser cutting machine is engineered to handle a variety of cross-sections, including round, square, rectangular, elliptical, angle, channel, I-beam, and other profiles.

Millspeed for steel

Cutting speed for steelwith carbide

* Owing to the real-time updating of products and technologies, the datas and product pictures on the site are for reference only

Materialcutting speedchart

BODORLASER INC. was established in April 2019 in Chicago, Illinois. Itâs the first subsidary of Bodor laser in the United States, which is committed to providing North America customers in manufacturing with highly efficient and reliable cutting solutions.

I hereby consent to Bodor Laser use the previously entered information to contact me about related product and feature updates, current offers and services. I can unsubscribe from these communications at any time.

Intelligent operation, efficient cutting, and an enjoyable user experience - that's what Bodor Laser brings to the table.

For more information on data protection can be found in our Privacy Policy. By providing a telephone number and submitting this form you are consenting to be contacted by SMS text message. Message & data rates may apply. You can reply STOP to opt-out of further messaging.

0086-813-8127573

0086-813-8127573