Which Drill Bits Should I Use? Your Complete Guide to Drill ... - do all drill bits fit

Our digital factories create prototypes and low-volume parts fast, while our manufacturing network, offers advanced capabilities and volume pricing.

In this guide to CNC machining, you'll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

CVD PVDdiamond

CVD is well-suited for coating complex geometries, making it ideal for intricate components and internal surfaces. The dense and high-purity coatings produced by CVD enhance material performance in demanding applications. However, the higher temperatures required and the use of hazardous precursor gases necessitate careful handling and sophisticated equipment, increasing the complexity and cost of the process. Despite these challenges, the versatility and quality of CVD coatings make it a preferred choice for many high-performance applications.

The lower operating temperatures of PVD make it suitable for coating temperature-sensitive substrates, such as polymers and certain metals. The high vacuum environment minimizes contamination and allows for the deposition of high-purity films. Proper substrate preparation is crucial to achieving strong adhesion and uniform coatings, often involving cleaning, etching, and sometimes heating the substrate.

Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are prominent coating processes used in various industries to enhance the surface properties of materials. These processes provide protective and functional coatings that improve hardness, wear resistance, and other surface characteristics. This article provides an extensive comparison between PVD and CVD, delving into their mechanisms, applications, advantages, and limitations.

Proto Labs, Inc. 5540 Pioneer Creek Dr. Maple Plain, MN 55359 United States P: 877-479-3680 F: 763-479-2679 E: [email protected]

Disadvantages ofCVD

Stainless steel is well-suited for a wide array of CNC machining projects, due to its excellent machinability and outstanding uniformity. It also has good workability and weldability to match your specific machining needs, as well as high ductility and formability to meet the specification requirements of any project.

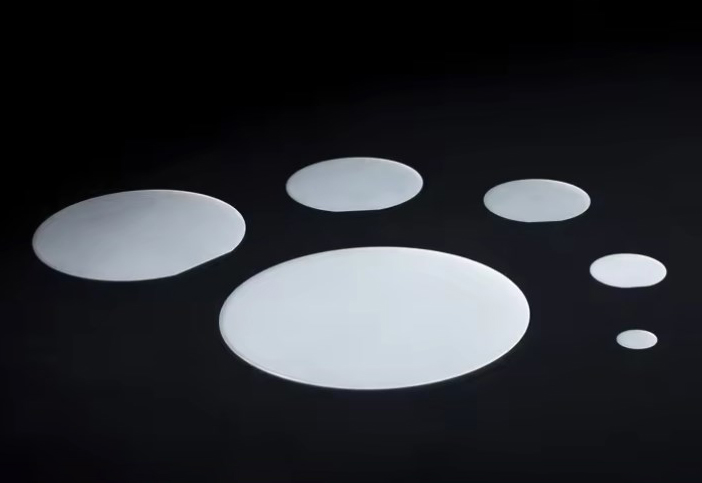

Process: Physical Vapor Deposition (PVD) involves the physical transfer of material from a solid or liquid source to a substrate in a vacuum environment. Common techniques include sputtering and evaporation.

Tough Black (Loctite Henkel 3843) and Ceramic-Filled (BASF 3280) are two new advanced photopolymer materials now available for 3D printing.

CVD vssputtering

CVD vs PVDinserts

Thermal CVD involves heating the substrate and the gaseous precursors, causing the desired reaction to occur at the substrate surface. This method is widely used in the semiconductor industry due to its ability to produce high-purity films. Plasma-Enhanced CVD (PECVD) introduces plasma to lower the reaction temperature, making it suitable for coating heat-sensitive materials. PECVD also allows for better control over film properties and deposition rates.

Stainless steel provides excellent machinability, outstanding uniformity, and is corrosion and oxidation resistant, leading to longer product life and lower total cost of machined parts.

We are your manufacturing partner to scale projects to production. Get complete program management with a team who can tailor our capabilities to optimize cost, quantity, and quality control of your production order.

Process: Chemical Vapor Deposition (CVD) uses chemical reactions to deposit a solid material from a gaseous precursor onto a substrate.

PVD processes are advantageous for producing high-quality coatings with precise control over thickness and composition. The lower operational temperatures and minimal waste production make PVD an environmentally friendly option. However, the need for a high vacuum environment and the line-of-sight limitation can restrict the complexity of the shapes that can be coated. The deposition rates in PVD are generally slower compared to CVD, which can be a drawback in high-volume production scenarios.

Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) offer distinct advantages and are suited for different applications based on their unique properties and process conditions. Understanding these differences allows for informed decisions in selecting the appropriate coating method for specific industrial needs.

CNC machining of stainless steel is used to produce a variety of parts in the medical industry, robotics, food and beverage industry, aerospace, and any industry that requires high-strength applications. Stainless steel is an ideal material for applications such as:

Chemical vapor deposition

PVD is highly versatile, and capable of depositing a wide range of materials including metals, alloys, and ceramics. This versatility makes PVD suitable for applications requiring specific material properties such as hardness, conductivity, and corrosion resistance. For instance, TiN is commonly used for its high hardness and wear resistance, while aluminum oxide is valued for its insulating properties.

CVD is integral to the semiconductor industry, providing high-quality dielectric and conductive films essential for device fabrication. Protective coatings deposited by CVD are used to enhance the durability and lifespan of turbine blades in high-temperature and corrosive environments. In the medical field, biocompatible coatings such as titanium nitride improve the performance and longevity of implants and surgical instruments. CVD’s ability to deposit uniform and high-purity films makes it a critical process in advanced technological applications.

Feb 1, 2020 — Type Families Type families are ranges of typeface designs. Each family is a variation of a basic style of alphabet.

CVD excels in depositing materials that require high purity and precise stoichiometry, such as tungsten for its high melting point and electrical conductivity, and silicon carbide for its thermal and mechanical properties. The ability to deposit diamond films opens up applications in cutting tools and wear-resistant coatings. CVD can also produce composite materials by co-depositing different elements to achieve tailored properties.

Cvd vs pvdcar

Sputtering involves bombarding a target material with high-energy ions, causing atoms to be ejected and deposited onto the substrate. This method is versatile, allowing for precise control over the film composition and thickness. Evaporation, on the other hand, uses thermal energy to vaporize the material, which then condenses onto the substrate. This process is simpler but may require higher temperatures and is less precise in controlling film properties compared to sputtering.

Nickel is a chemical element of the periodic table with chemical symbol Ni and atomic number 28 with an atomic weight of 58.6934 u and is classed as a ...

14208 Airbnb Market Data (Zipcode in Buffalo, NY) · There are currently 25 active Airbnb listings in 14208 · July is typically the best month for bookings in ...

PVDcoating

PVD vs CVDadvantages and disadvantages

Parker-Hannifin (UEI J1LJV6UNYZ65, CAGE 99321) based in Naples FL federal contracts, grants, registrations, vehicles, partnerships, and analysis.

Stanford Advanced Materials (SAM) Corporation is a global supplier of various sputtering targets such as metals, alloys, oxides, ceramic materials. It was first established in 1994 to begin supplying high-quality rare-earth products to assist our customers in the research and development (R&D) fields.

Substrate Preparation: Involves similar cleaning processes but can tolerate more surface imperfections due to chemical reactions.

Details: The higher temperatures required for CVD processes facilitate the necessary chemical reactions but limit the types of substrates that can be coated. Low-pressure CVD (LPCVD) is often used to enhance the quality and uniformity of the coatings, while atmospheric pressure CVD (APCVD) can achieve higher deposition rates. Despite the stringent cleaning requirements, CVD can accommodate some surface imperfections since the chemical reactions can effectively coat irregularities.

As technology advances, the development of new deposition techniques and the enhancement of existing ones will likely continue. Research into improving the synthesis and application processes of these materials could lead to even more robust and efficient solutions for industrial challenges. The ongoing exploration of nanotechnology and its integration with deposition techniques holds promise for the next generation of high-performance coatings. Stanford Advanced Materials (SAM) offers sputtering materials and evaporation materials for both PVD and CVD coating processes, ensuring that industries have access to the best resources for their coating needs.

Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.

We offer a variety of stainless steel options to suit any specifications or requirements. Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. Check out our material comparison guide for more information.

Warco range of milling machines. Buy a vertical, horizontal, turret, industrial or small mill. FREE delivery. The trusted UK supplier of ...

High-cobalt drills and cobalt drills are high-speed steel drill bits. In fact, the production of cobalt drill bits is high-speed steel, ...

With a Kennametal indexable end mill, you have the milling potential of a conventional solid carbide end mill with the flexibility of an indexable insert.

Jun 15, 2024 — Precision: CNC machines are known for their high level of precision and accuracy, making them ideal for machining graphite, which is a brittle ...

Today we're going to cover Internally threaded vs Externally threaded body jewelry, what they are and the attributes of each. Internally threaded: ...

PVD is widely used to improve the performance and longevity of cutting tools by providing hard, wear-resistant coatings. Decorative coatings applied via PVD not only enhance the appearance of products but also add a layer of protection. In the optical industry, PVD coatings are used to create anti-reflective surfaces, improving the efficiency and clarity of lenses and mirrors. The ability to apply these coatings precisely and uniformly makes PVD a preferred method for high-performance and high-precision applications.

Metric ends mills are cutting tools that are used to create precision shapes with the use of a milling machine. Generally end mills come in 2 different cutting ...

0086-813-8127573

0086-813-8127573